Microwave feed port structure based on wood medium

A microwave and feeder technology, applied in the field of microwave heating system equipment, can solve the problems of microwave puffing equipment research not meeting industrialization requirements, residence, power and processing capacity limitations, etc., to achieve uniform ventilation, concentrated microwave field, and reduced The effect of a fire situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0021] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

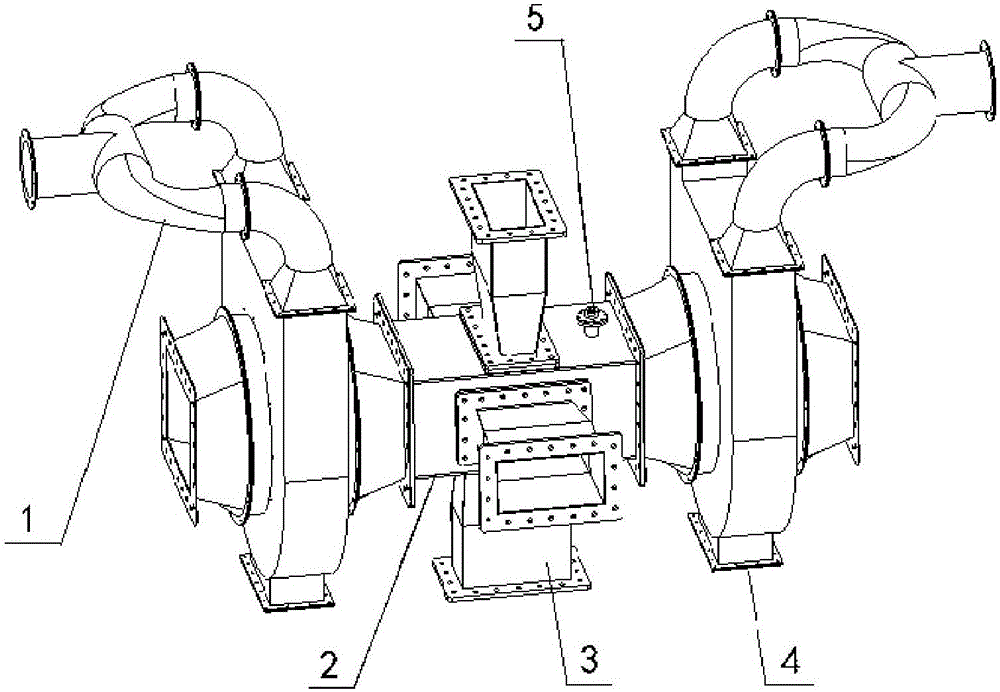

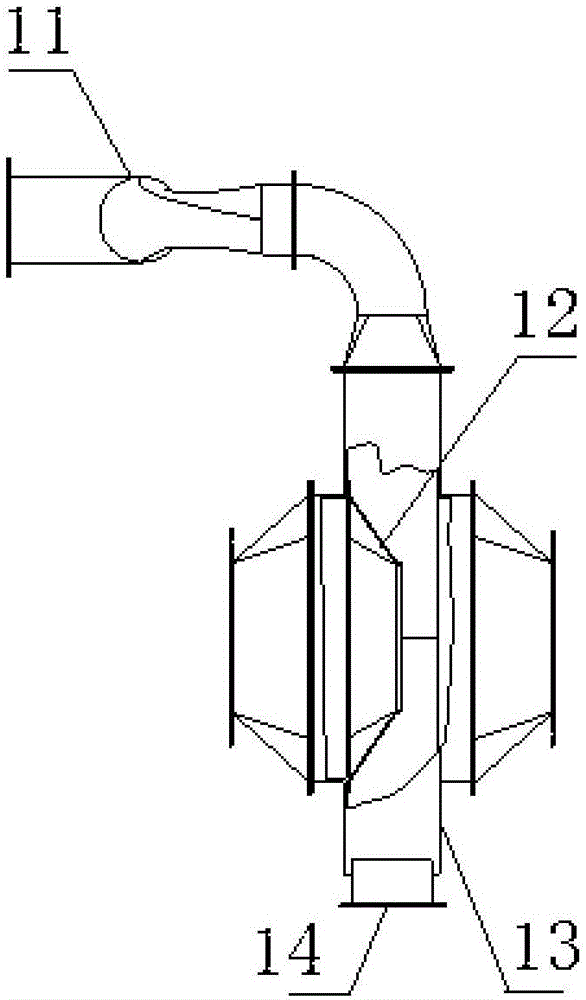

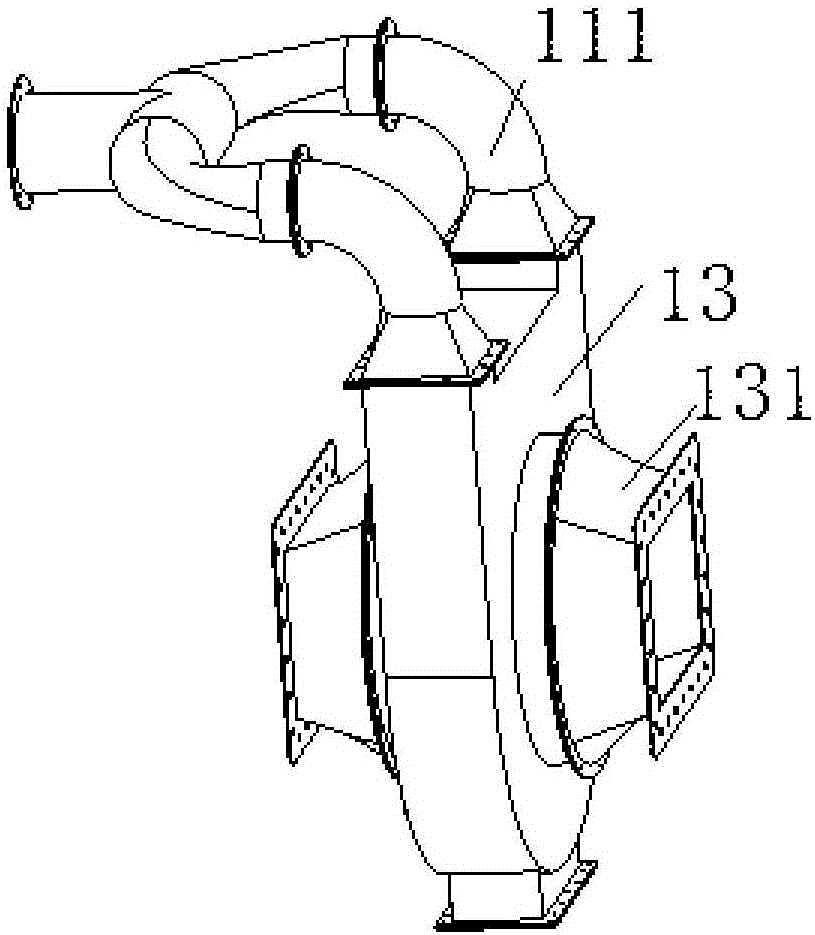

[0022] Such as figure 1 As shown, a microwave feeder structure based on wood as a medium according to a specific embodiment of the present invention includes a heating cavity 2, four identical microwave feeder waveguides 3, a hot air inlet device 1, a hot air outlet device 4 and The temperature measuring device 5, wherein each microwave feeder waveguide 3 is in a shrinking shape, and the four identical microwave feeder wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com