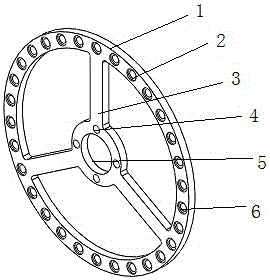

Turnplate of cage shaft

A turntable and disc spoke technology is applied in the field of automatic sweet potato washing machines, which can solve the problems of wasting water, destroying the skin structure of sweet potatoes, and draining sewage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the technical scheme of the present invention, now in conjunction with accompanying drawing, illustrate the specific implementation manner of the present invention; figure 1 In this example, the aluminum alloy material is selected as the material of the disc circumference 1, the disc spokes 3, and the hub 5. In this example, the diameter of the disc circumference 1 is 600 mm as an example, and the width of the disc circumference 1 is 30 mm, and the thickness is 15 mm. The width of the disc 3 is 30 mm, the thickness is 10 mm, and the outer diameter of the hub 5 is 150 mm, the inner diameter is 50 mm, and the thickness is 15 mm; the purpose of this is to reduce the weight of the turntable, reduce the rotational inertia, and at the same time facilitate the movement of sweet potatoes between the spokes. In and out; the diameter of the cage rod mounting hole 2 is selected to be 10 mm, and the spacing is 40 mm; the flange connection hole 4 is sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com