Vacuum dust filtering device realizing convenient cleaning

A dust filter device and filter device technology, which is applied in the field of metallurgy, can solve the problems of affecting the service life of container seals, troubles, and time-consuming problems, and achieve the effects of reducing disassembly, simple cleaning operations, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

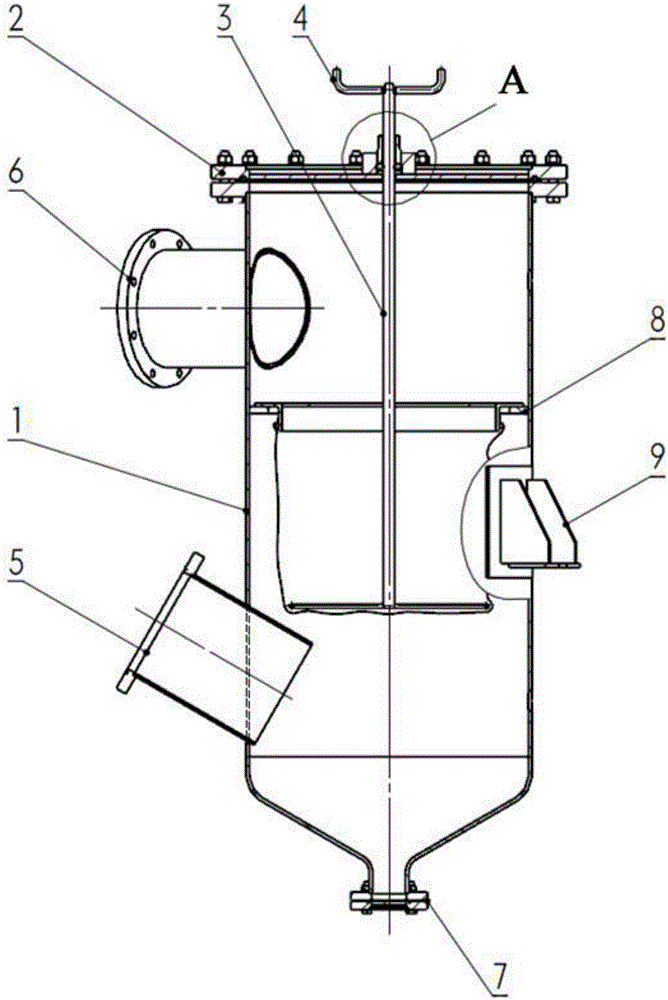

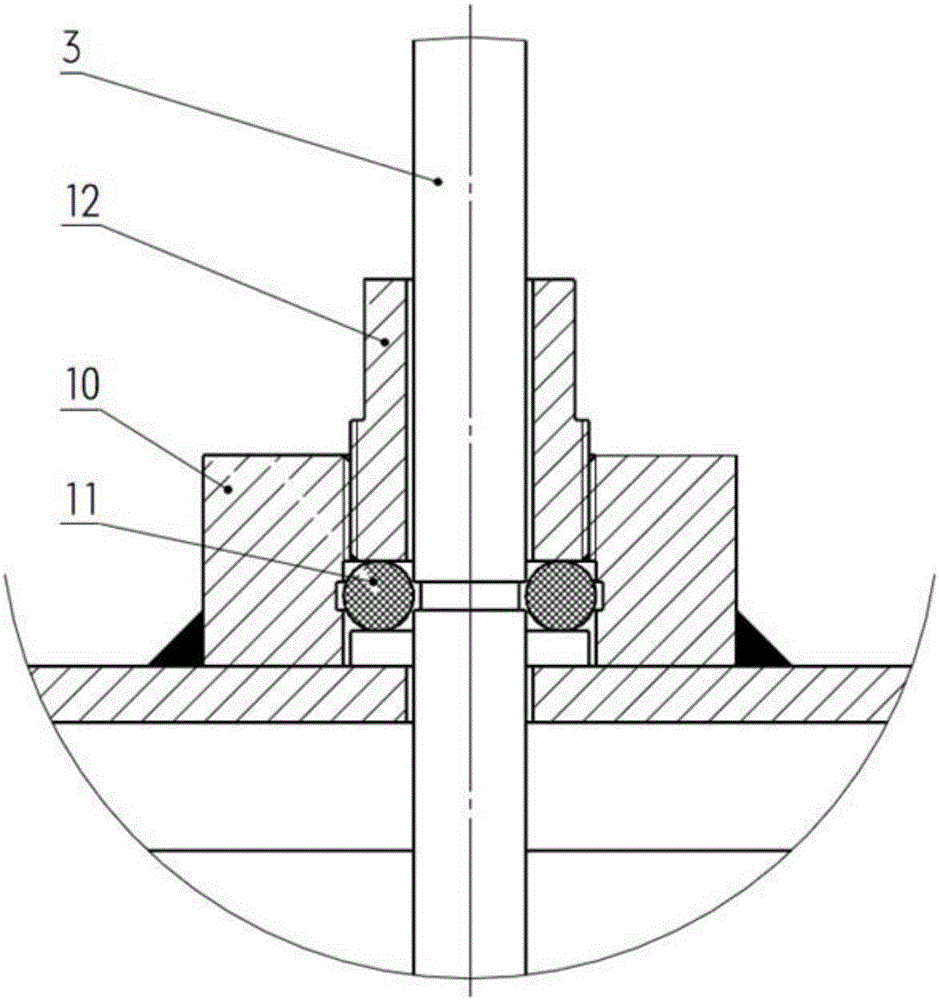

[0021] The present invention is constituted as follows: it is mainly composed of a cylinder body 1, a head flange group 2, a filter device 3, a handle 4, an air inlet 5, an air outlet 6, a sewage outlet 7, a ring plate 8, an ear seat 9, The sealing seat 10, the sealing ring 11, and the nut 12 are composed, such as figure 1 , figure 2 shown.

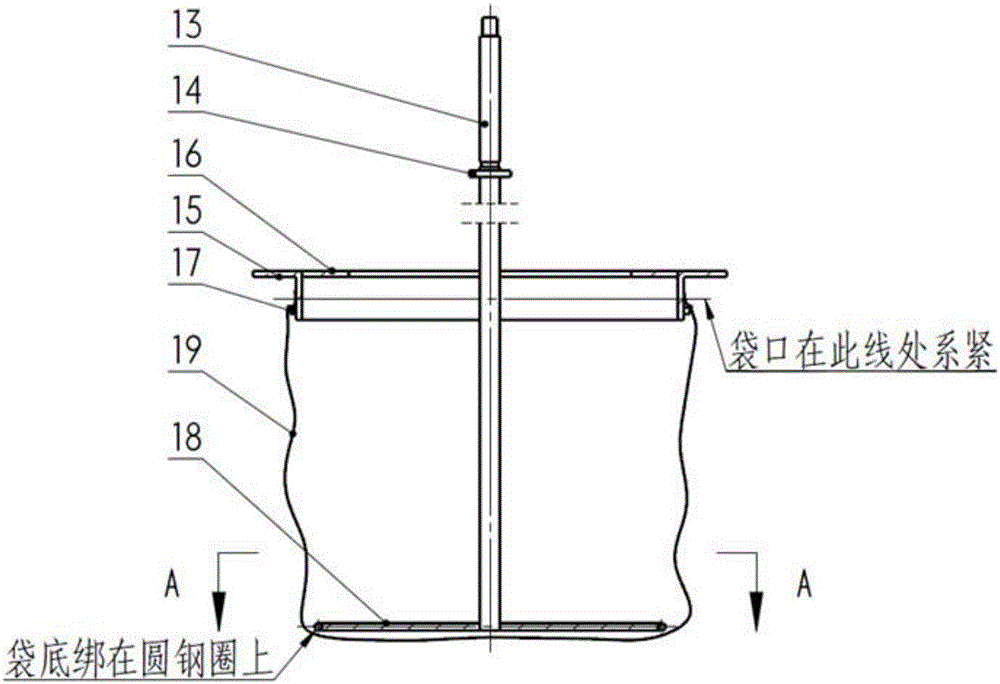

[0022] Among them, the head flange group 2 is composed of two vacuum flanges, one vacuum flange is welded with the cylinder body 1, the other vacuum flange is sealed with a blind plate, and the two flanges are connected by sealing gaskets and fasteners. Filtration device 3 is made up of pull rod 13, steel ring 14, angle steel ring 15, ring plate two 16, snap ring 17, round steel ring 18, PTFE filter cloth 19, as image 3 , Figure 4 shown. Angle steel ring 15, ring plate 2 16, and snap ring 17 need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com