A method of welding and swinging of robotics

A technology of robot welding and setting method, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. User experience with good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

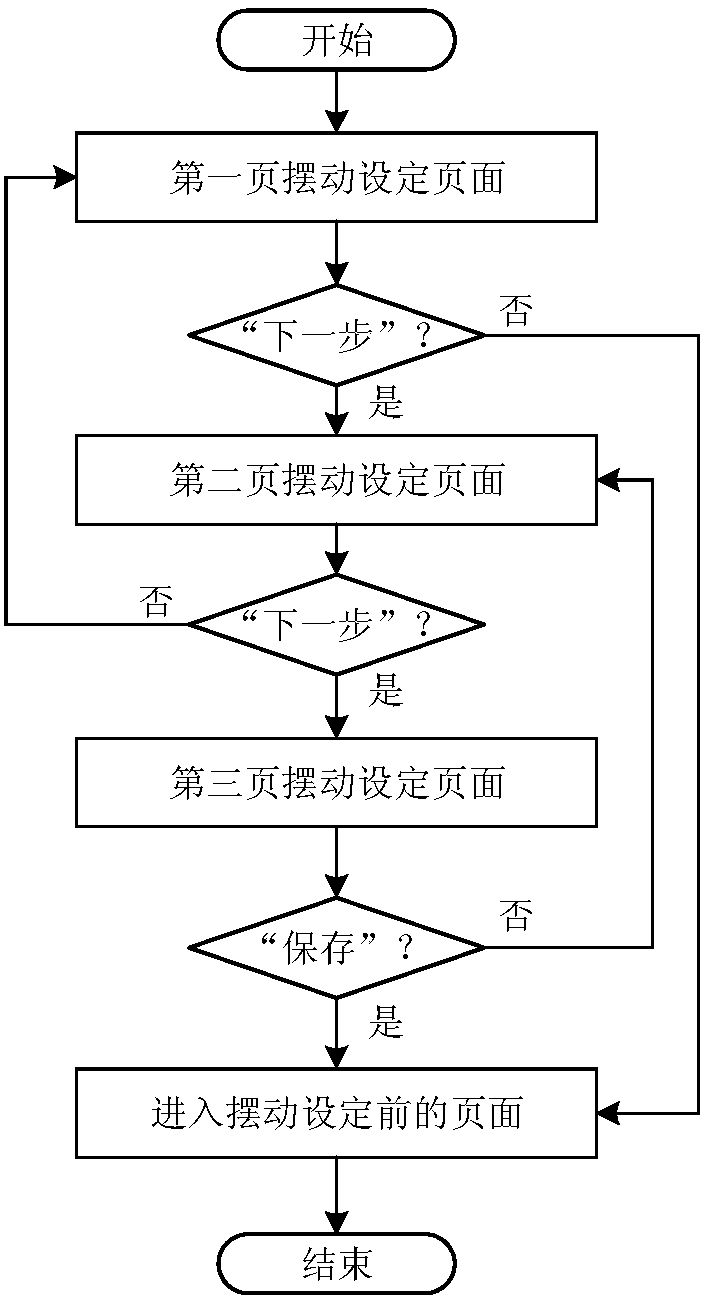

[0017] Such as figure 1 , 2 , 3 and 4, a robot welding swing setting method includes the following steps:

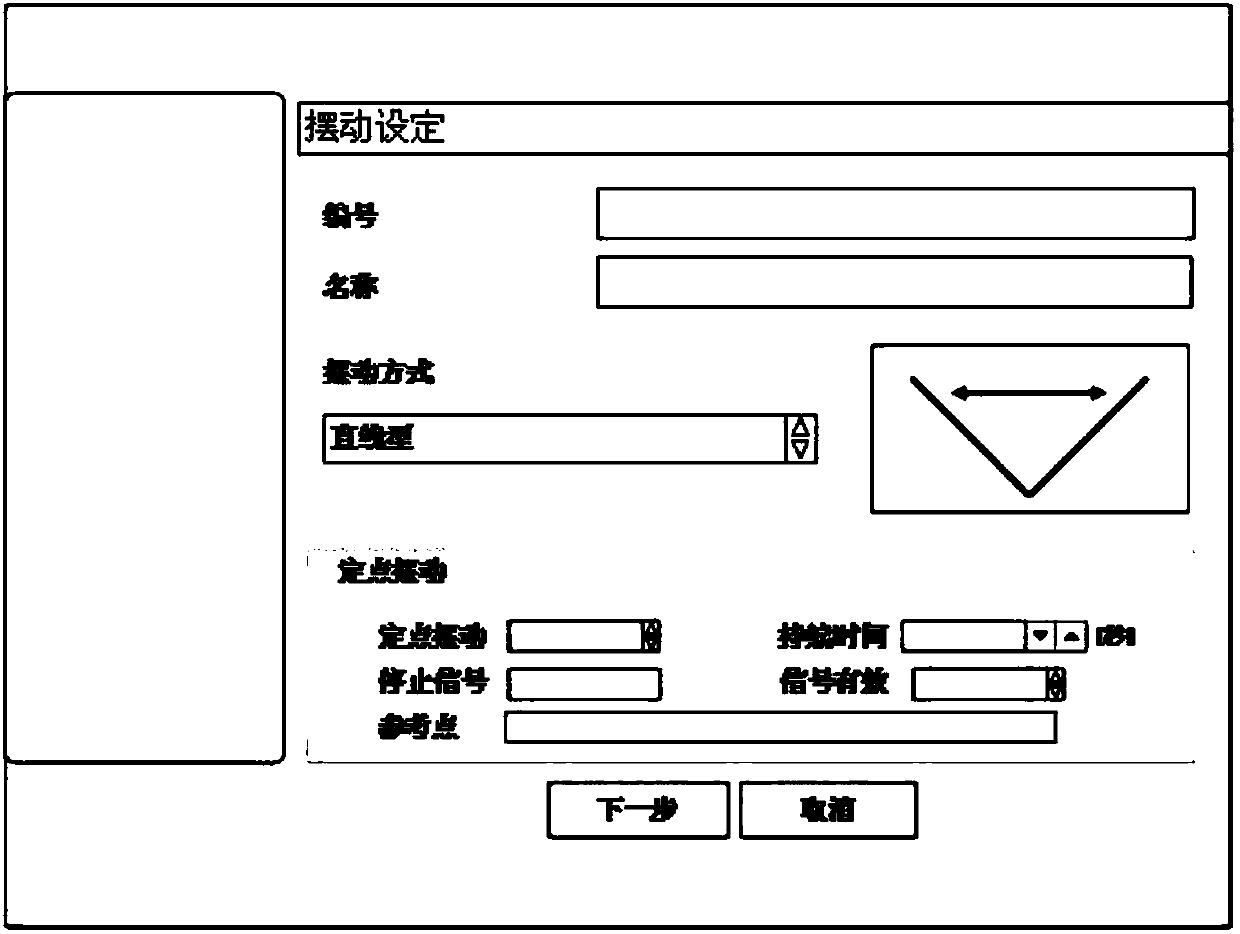

[0018] (1) Set the number and name of the swing condition on the first page, select a swing mode, and determine whether to enable fixed-point swing;

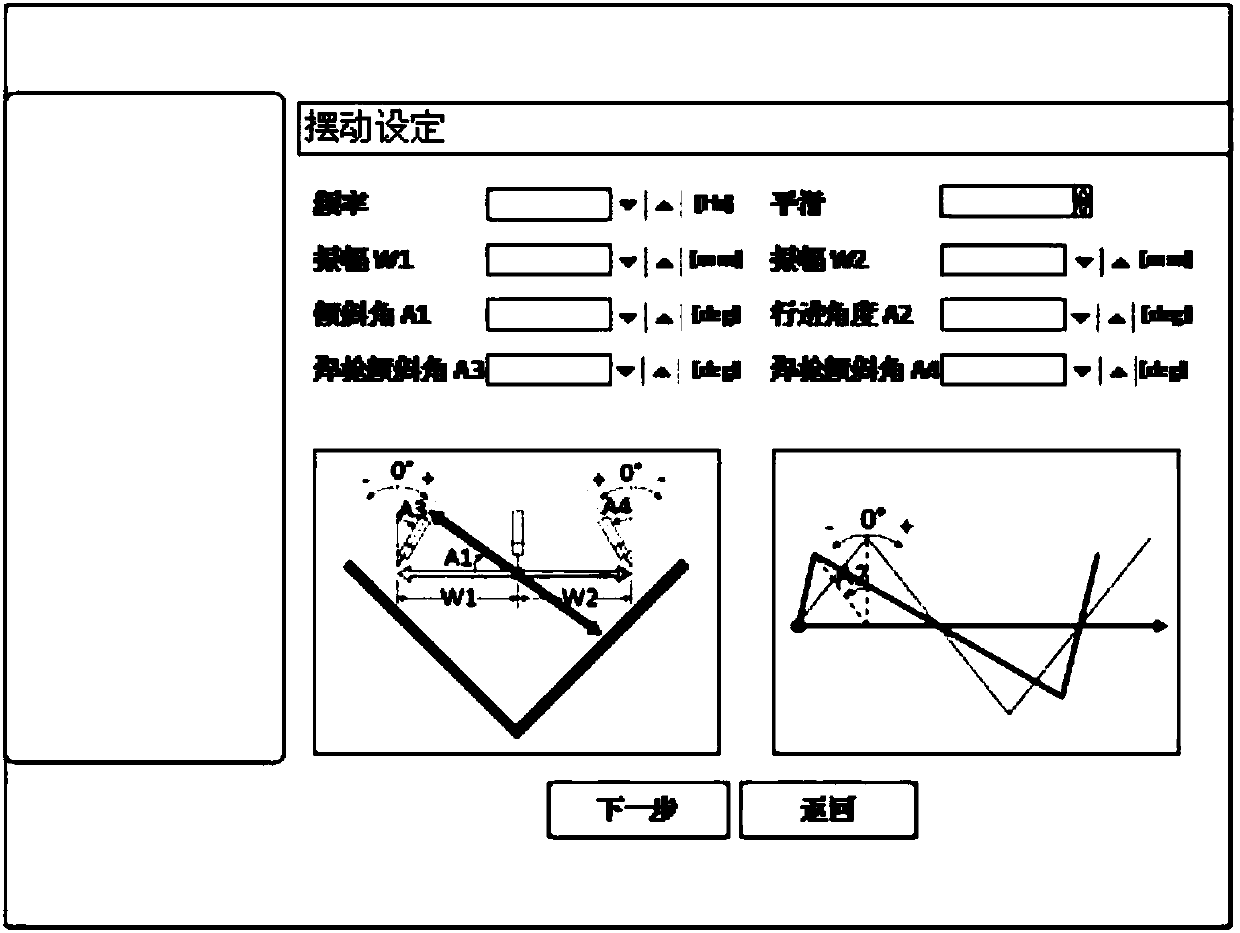

[0019] (2) The second page is the parameter setting page of the swing mode selected on the first page, setting parameters related to the shape of the swing track;

[0020] (3) The third page is the parameter setting page of the swing mode selected on the first page, set the swing start phase, swing delay time, stop position and stop time, save the swing setting, and the swing setting is completed.

[0021] The robot welding swing setting method adopts a multi-page display parameter mode. After selecting the swing mode on the first page, click the next page to enter the parameter setting page of the selected swing mode, and reasonably allocate the parameters of each page. A proper amount of parameters are arranged on eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com