Universal clamp device for total-length finish milling of turbine blades

A technology for steam turbine blades and fixtures, which can be used in positioning devices, manufacturing tools, metal processing equipment, etc., and can solve the problems of high tooling costs and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

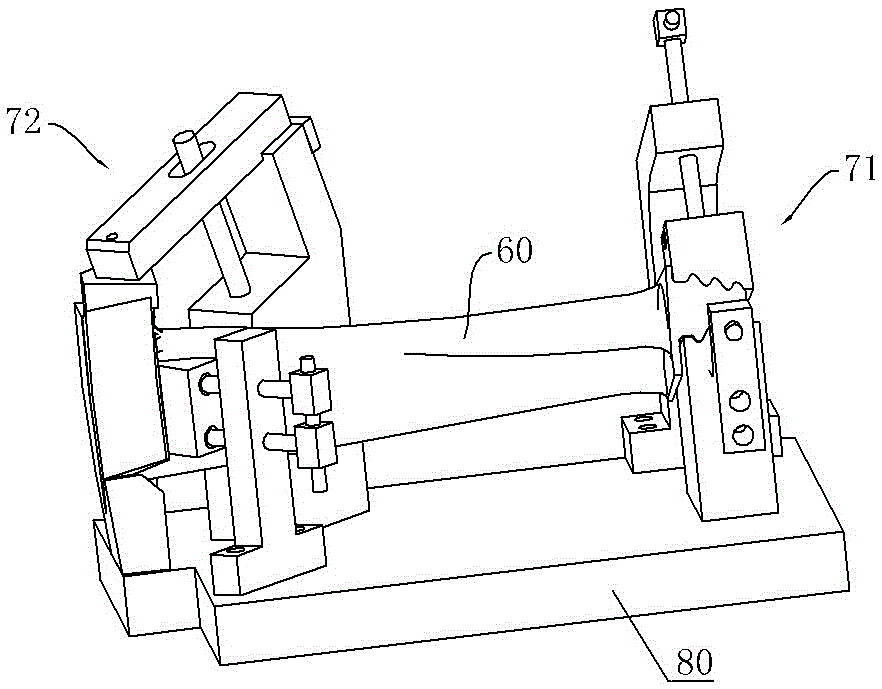

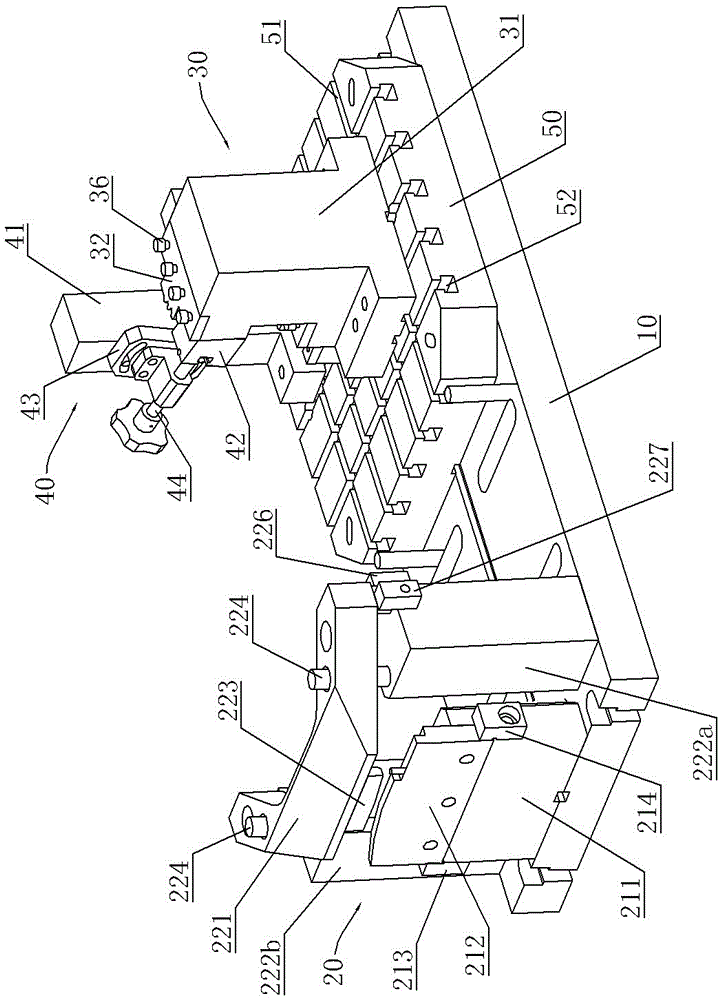

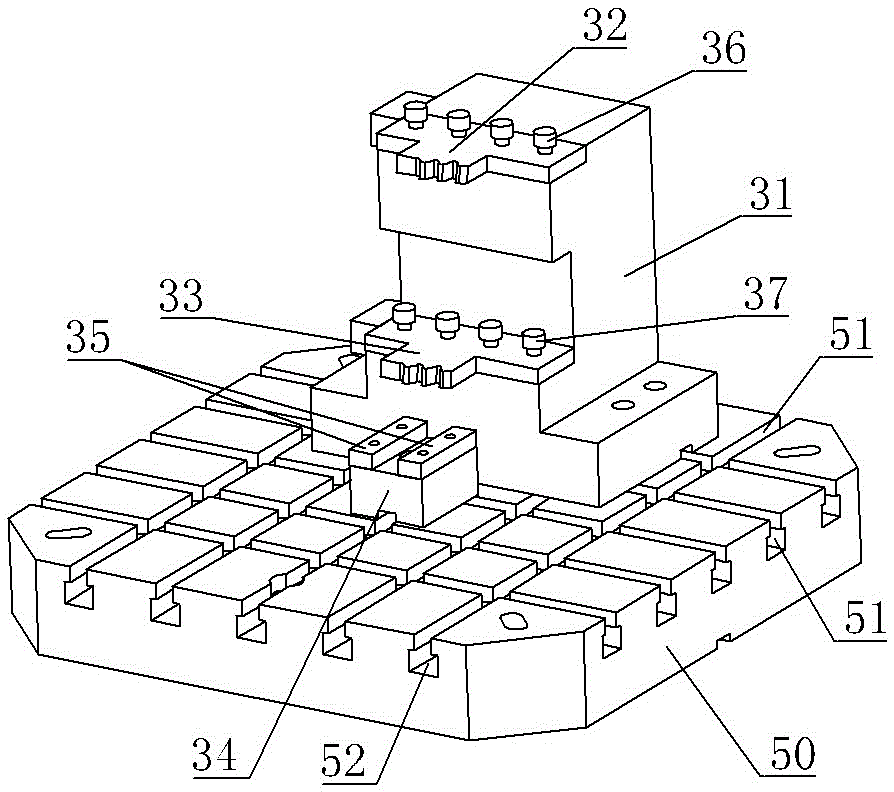

[0022] See figure 2 , the present invention is used for the universal clamping device of steam turbine blade total length finish milling, and it comprises base plate 10, and the horizontal end on base plate 10 is fixed with blade crown positioning and pressing assembly 20, and the other end is provided with blade root tooth shape positioning assembly 30 and the blade root tooth-shaped pressing assembly 40; the base plate 10 is fixed with a universal base plate 50, and the universal base plate 50 is provided with keyways 51 and 52 distributed in a grid shape that are vertically staggered and connected along the horizontal and vertical directions, wherein the keyways 51 are The keyway 52 is set along the horizontal direction, and the blade root tooth-shaped positioning assembly 30 and the blade root tooth-shaped pressing assembly 40 are assembled and connected with the keyways 51 and 52 on the general base plate 50 through positioning keys. 50 to adapt to the location and clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com