New unscrewing pliers for drill pipe

A new type of drill pipe technology, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of poor unscrewing effect and heavy manual working pliers, and achieve the effects of wide application range, light portability, and adjustable diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

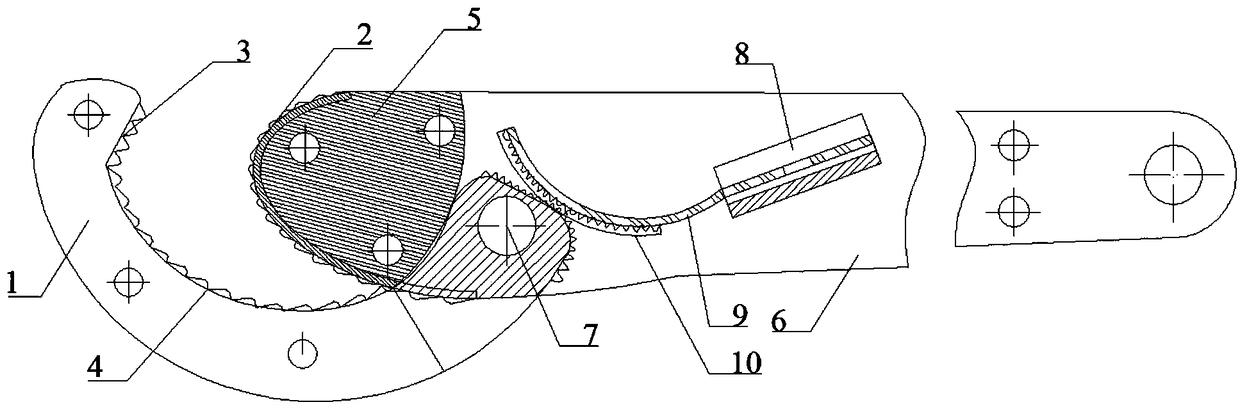

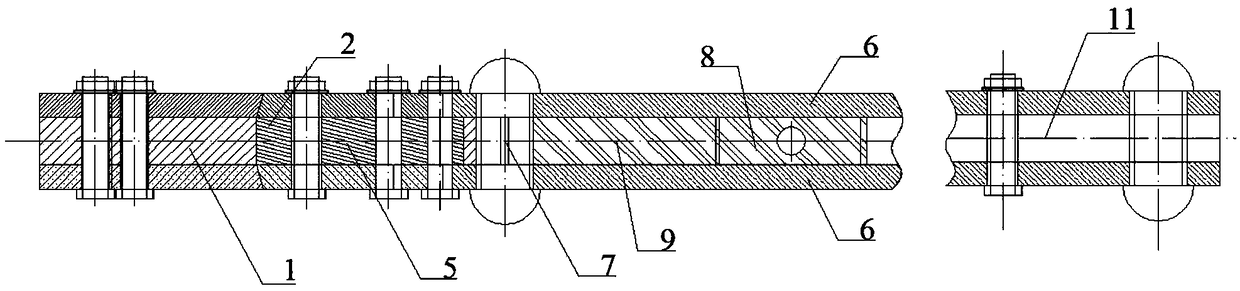

[0020] Below in conjunction with embodiment and its Figure 1-2 The present invention is described in further detail. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0021] like Figure 1-2 as shown, figure 1 It is the structural representation of the novel unscrewing pliers for drill pipe of the present invention, figure 2 for figure 1 top view.

[0022] A new type of unscrewing pliers for drill rods, including a movable jaw 1 and a fixed jaw 2; the inner jaw of the movable jaw 1 includes a planar occlusal end surface 3 and an arc-shaped concave clamping inner surface 4, the The angle between the plane where the opening of the clamping inner surface 4 is located (that is, the plane where the line between the two opening ends of the arc-shaped concave surface is located) and the occlusal end surface 3 is 65° to 80°, and the movable jaw 1 The rear end is hinged on the fixed jaw 2; the fixed ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com