Using method of tool

A tool and tool head technology, applied in the field of tool use, can solve problems such as low cutting efficiency, and achieve the effects of improving cutting efficiency, saving complicated steps and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

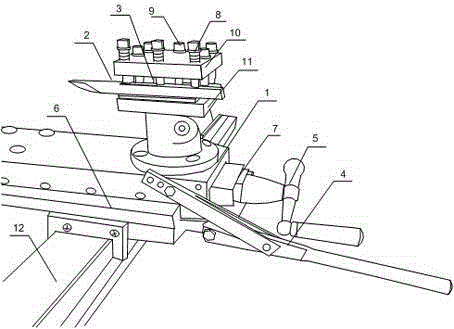

[0019] Such as figure 1 As shown, the present invention first places wood on the clamping device on the cutter, and the cutter head is placed on the base, the base is located on the slideway, and the slideway is placed on the clamping device or the guide rail of the machine tool. Under the adjustment of the push device, the blade is fixed in the tool head and moves on the slide along with the base, so that the blade is close to the wood for processing and polishing wood, and the hand push device is adjusted again so that the tool head and the base move along the slide in the clamping device or It moves on the guide rail of the machine tool to facilitate the grinding of different parts of the wood; it includes the base 1, the blade 2, the tool head 3, the slideway 6 and the hand pushing device. The hand pushing device is connected to the base 1 and the slideway 6 respectively. The cutter head 3 is connected to the base 1 , the base 1 is arranged on the slideway 6 , and the blad...

Embodiment 2

[0021] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment includes a handle 5, a screw rod 7 and an automatic rod 4. The handle 5 is screwed to the slideway 6 through a bolt 7, and the automatic rod 4 is connected to the base 1 hinged connection. Rotate the handle 5, through the threaded cooperation between the screw rod 7 and the slideway 6, the base 1 moves along with the slideway 6 on the guide rail 12 of the machine tool or the clamping device; push the automatic rod 4 up and down to make the base 1 move on the slide Do linear motion on the road 6.

Embodiment 3

[0023] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the cutter head 3 includes an upper baffle 10 and a lower baffle 11, the lower baffle 11 is provided with a connecting column 9, and the upper baffle 10 is fixed on the connecting column 9, Fastening bolts 8 are arranged between the two plates, and the blade 2 is placed between the upper baffle 10 and the lower baffle 11 . The upper baffle 10 and the lower baffle 11 are fixed by the connecting column 9 to form a space, adjust the position of the blade 2, and then fix the blade 2 on the tool head 3 by rotating the fastening bolt 8; the fastening can be adjusted according to different situations Bolts 8 are used to replace blades 2 of different types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com