Connection structure and method of electric motor coach overhead type battery

An electric passenger car and connection structure technology, applied in the superstructure of passenger cars, battery/battery traction, electric vehicles, etc., can solve the problems of low connection strength and can not meet engineering needs, and achieve the effect of sufficient heat dissipation and enhanced connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

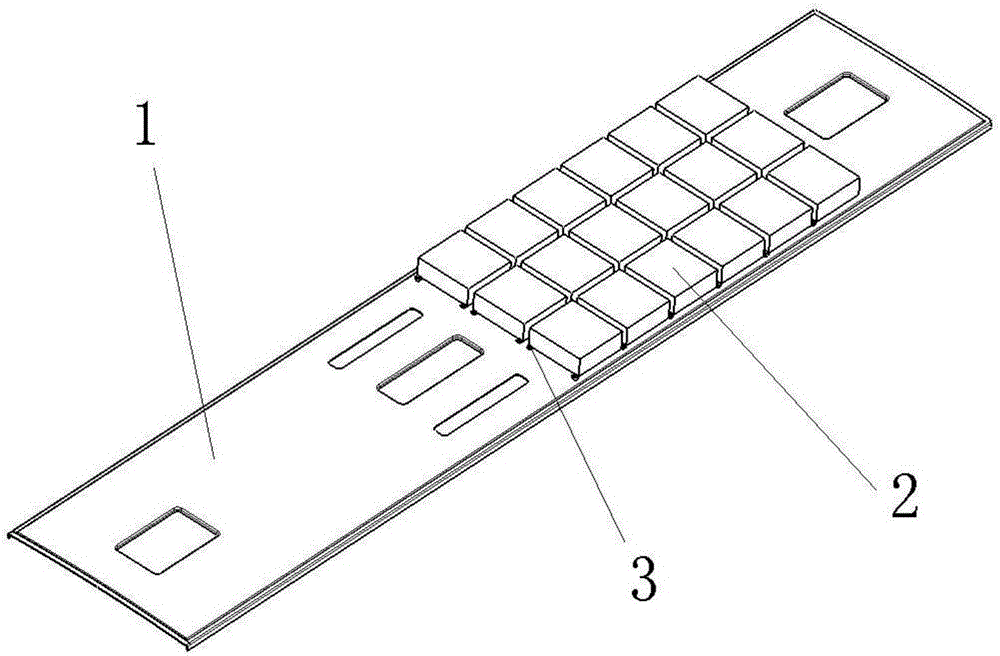

[0024] A connection structure for a top-mounted battery of an electric bus, the body of the electric bus is made of composite materials, the top-mounted battery is the main power source of the electric bus, and the connection structure includes a top-mounted battery, a battery support seat group and a composite material vehicle Top; the top-mounted battery includes a plurality of battery units, each battery unit weighs no more than 100 kilograms, and each battery unit is provided with a connecting tab; the plurality of battery units are arranged in a matrix; the battery The supporting base group includes a plurality of battery supporting bases, and the multiple battery supporting bases are arranged in a matrix;

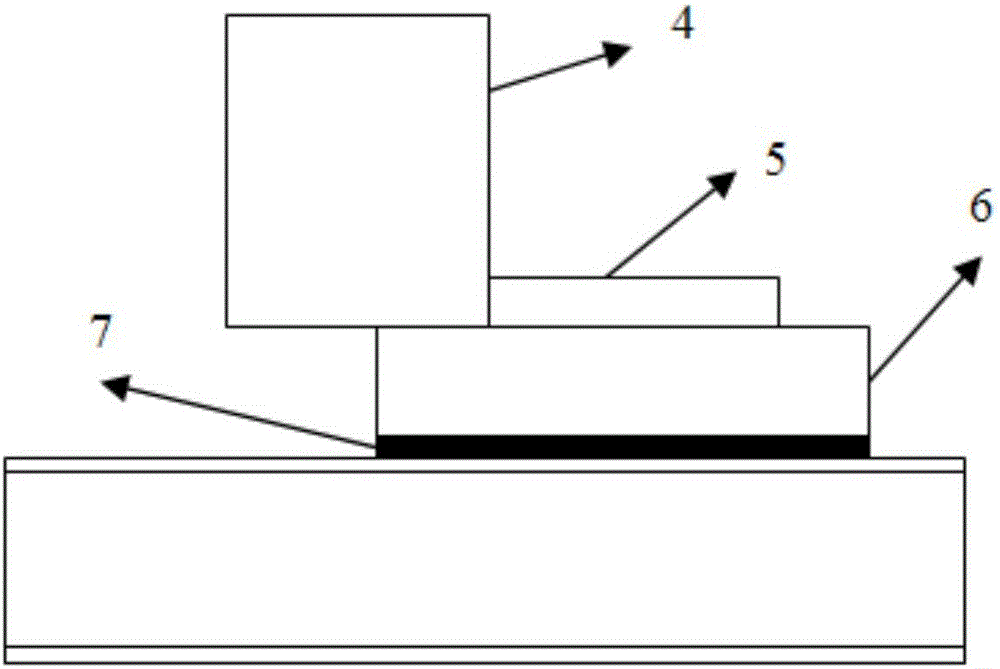

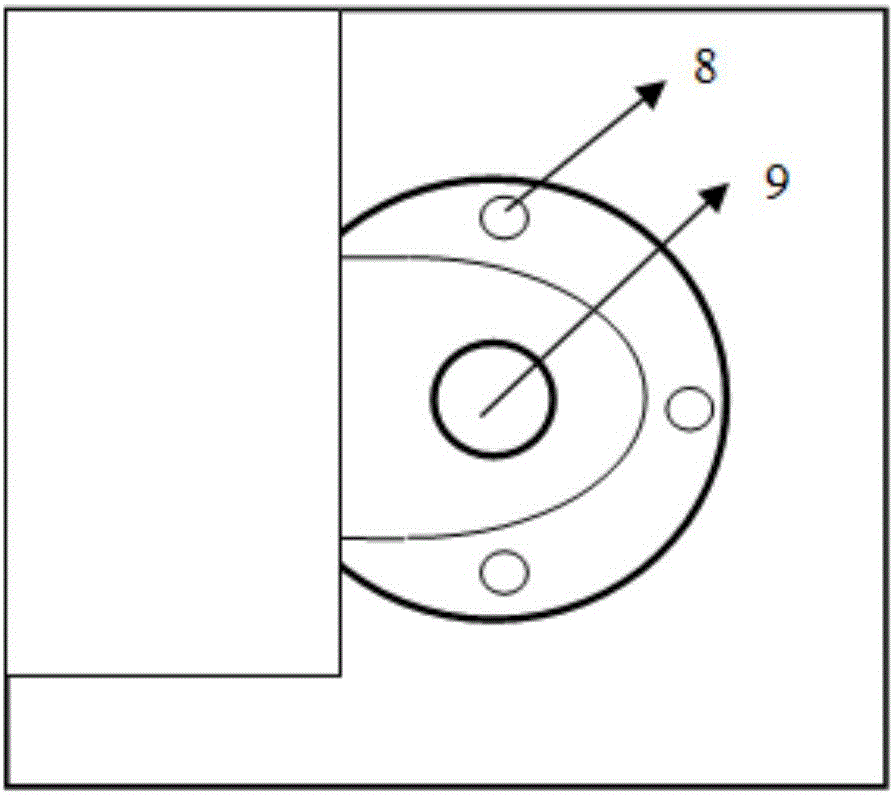

[0025] The roof of the electric passenger car is a composite material sandwich panel, and the lower surface of each battery support seat is ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com