Bumper system imitating bamboo structure

A technology of bumper and bamboo, which is applied in the direction of bumper, vehicle safety arrangement, transportation and packaging, etc. It can solve the problems of high manufacturing cost, inconvenient installation, low energy absorption efficiency, etc., and achieve good energy absorption effect and good integrity , the effect of enhancing the ability to absorb energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

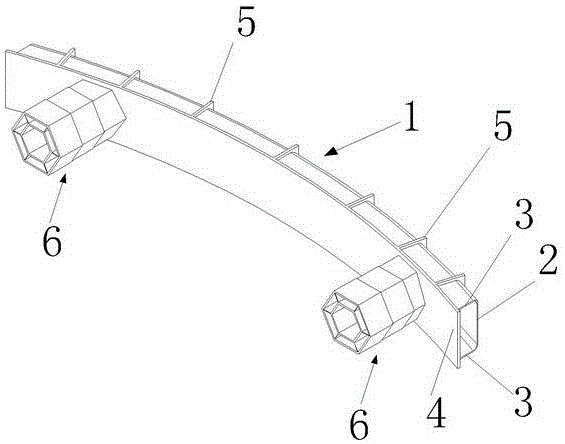

[0017] see figure 1 As shown, the present invention is composed of a bumper beam 1 and a bionic energy-absorbing box 6. The bumper beam 1 is composed of a front arc-shaped panel 2, a rear arc-shaped panel 4 and a cover plate 3. The bionic reinforcing rib 5 is welded, and several bionic reinforcing ribs 5 are distributed on the outline of the bumper beam 1. The existence of the bionic reinforcing rib 5 can ensure a certain rigidity of the bumper beam 1 while improving its bending resistance. Stablize. The crash box 6 is arranged on the rear arc-shaped panel 4 .

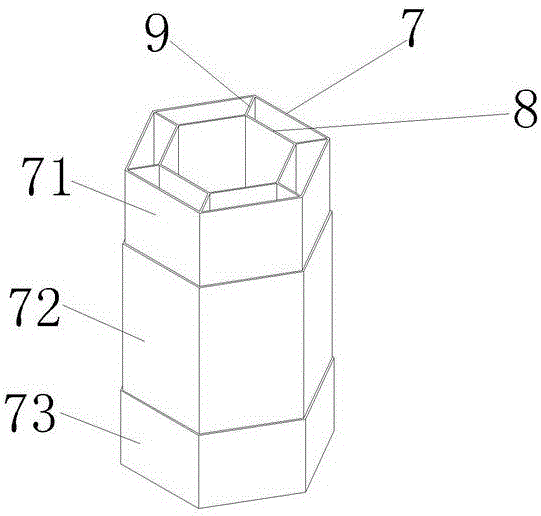

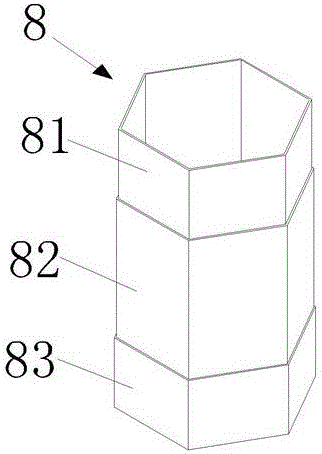

[0018] see figure 2 As shown, the bionic energy-absorbing box 6 is composed of a bionic shell 7, a bionic inner tube 8 and a restraint rib 9. The bionic shell 7 is a variable-wall hexagonal tube with the same inner diameter and different wall thickness, and the wall thickness is from top to bottom. Gradually increasing, the bionic shell 7 is composed of a first section shell 71, a second section shell 72, and a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com