Full-automatic packaging equipment

A fully automatic packaging and equipment technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of low packaging efficiency, inconvenient film cutting, poor packaging effect, etc., and achieve high efficiency and good packaging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

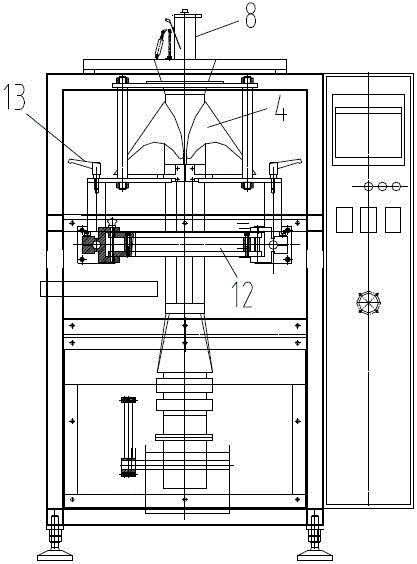

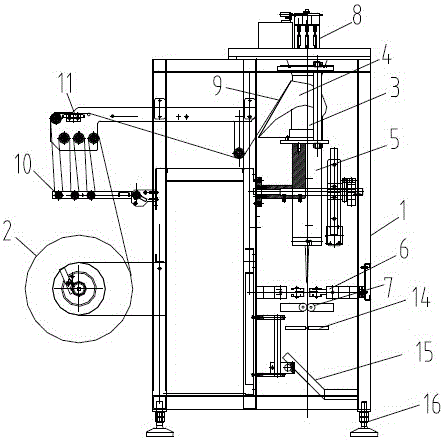

[0014] As shown in the figure, a fully automatic packaging equipment includes a frame 1, a reel film roll 2 is arranged on the rear side of the frame, a filling cylinder 3 is arranged on the upper part of the frame, and a film is arranged on the filling cylinder Slitting guide block 4, the lower part of the filling cylinder is provided with a longitudinal edge banding device 5, the lower part of the longitudinal edge banding device is provided with a transverse edge banding device 6, and the lower part of the transverse edge banding device is provided with a device that drives the packaging bag forward and simultaneously drives The reel film roll continuously rotates a power roll 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com