Conversion method for five blanking stock bins of lifter

A conversion method, hoist technology, applied in the direction of conveyor, transportation and packaging, etc., to achieve the effect of saving equipment investment, less investment and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

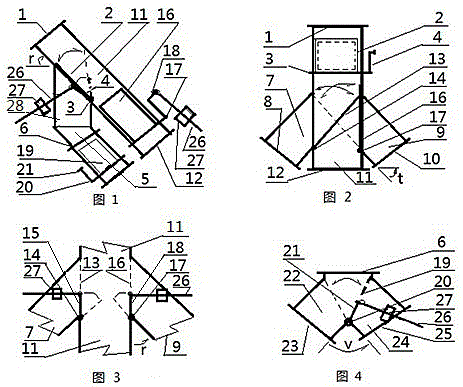

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] The conversion method of feeding five silos with one elevator, including: feeding port 1 of the feeding converter, opening and closing door 2 of A, door shaft 3 of door A, crank arm of door shaft A 4, and feeding pipe 5 , Flange 6 attached to the feeding pipe, left pants pipe 7 of the main feeding pipe, flange 8 of the feeding pipe of No. Feeding pipe 11, feeding pipe flange 12 of No. 2 silo, No. B opening and closing door 13, No. B door shaft 14, No. B door shaft crank arm 15, No. C opening and closing door 16, No. C door shaft 17, and No. C door shaft Door hinge arm 18, D conversion door 19, D door hinge 20, D door hinge arm 21, left underpants tube 22 with feeding pipe, feeding pipe flange 23 of No. 4 silo, feeding pipe attached Right underpants pipe 24, No. 5 material bin feeding pipe flange 25, electric screw rod 26, screw motor 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com