Part tray lifter

A technology for lifting pallets and parts, which is applied to conveyors, mechanical conveyors, rollers, etc., and can solve problems that affect production beats, poor safety, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

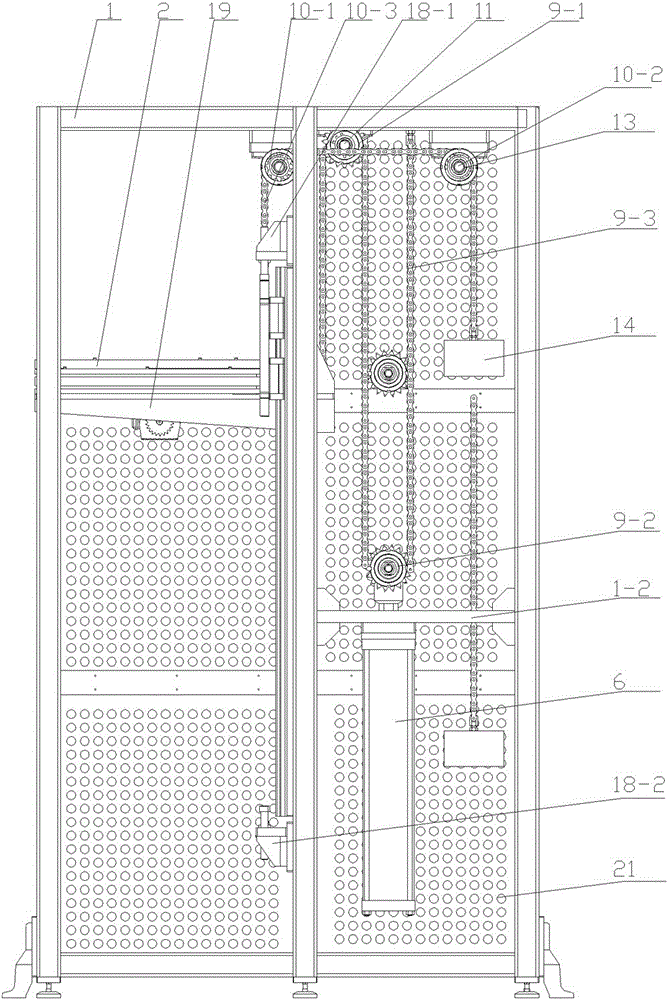

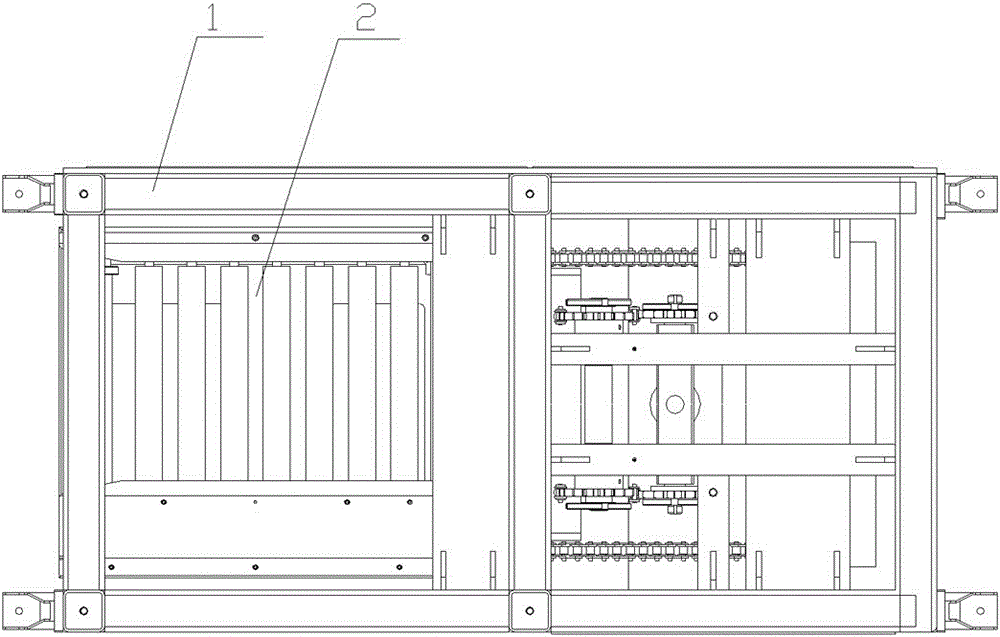

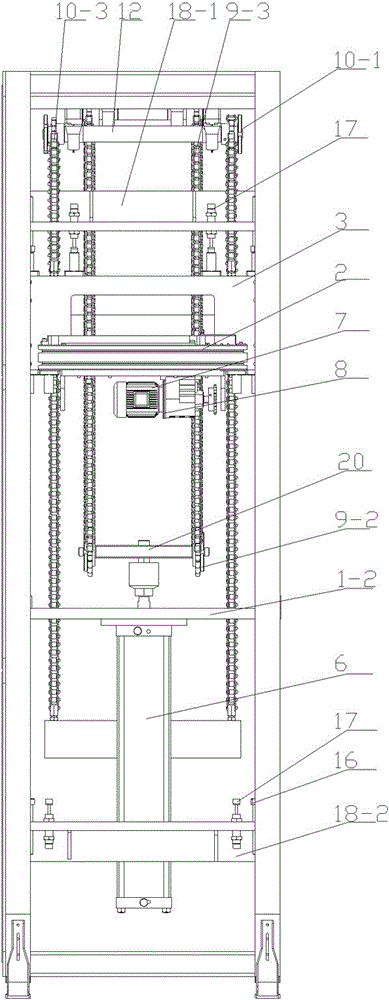

[0025] figure 1 , figure 2 , image 3 , Figure 4 Middle: frame 1, support frame 1-1, support plate 1-2; roller conveying seat 2, roller 2-1, inclined guide plate 2-2; lifting seat 3; guide rail 4; slider 5; cylinder 6; transmission Motor 7; mounting frame 8; first chain structure 9, first sprocket wheel 9-1, second sprocket wheel 9-2, first chain 9-3; second chain structure 10, third sprocket wheel 10-1, Fourth sprocket 10-2, second chain 10-3; first connecting shaft 11, second connecting shaft 12, third connecting shaft 13; counterweight 14; sleeve 15; limit post 16, buffer limit Column 17; upper limit installation plate 18-1, lower limit installation plate 18-2; fixed plate 19; connecting plate 20; protective plate 21.

[0026] See Figure 1-Figure 4 As shown, a parts tray hoist includes a frame 1, a roller conveying seat 2, and rollers 2-1 are arranged on the roller conveying seat 2, and a plurality of parallel rollers 2-1 arranged side by side pass through sprockets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com