Cold wall furnace for preparation of graphene through CVD method and continuous production method

A graphene and fireplace technology, applied in the field of graphene preparation, can solve the problems of quartz tube bursting, high cost, safety production accidents, etc., and achieve the effects of saving costs, improving efficiency, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

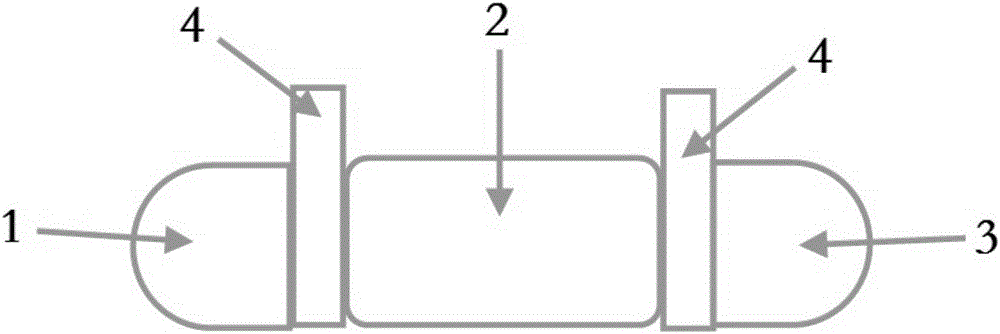

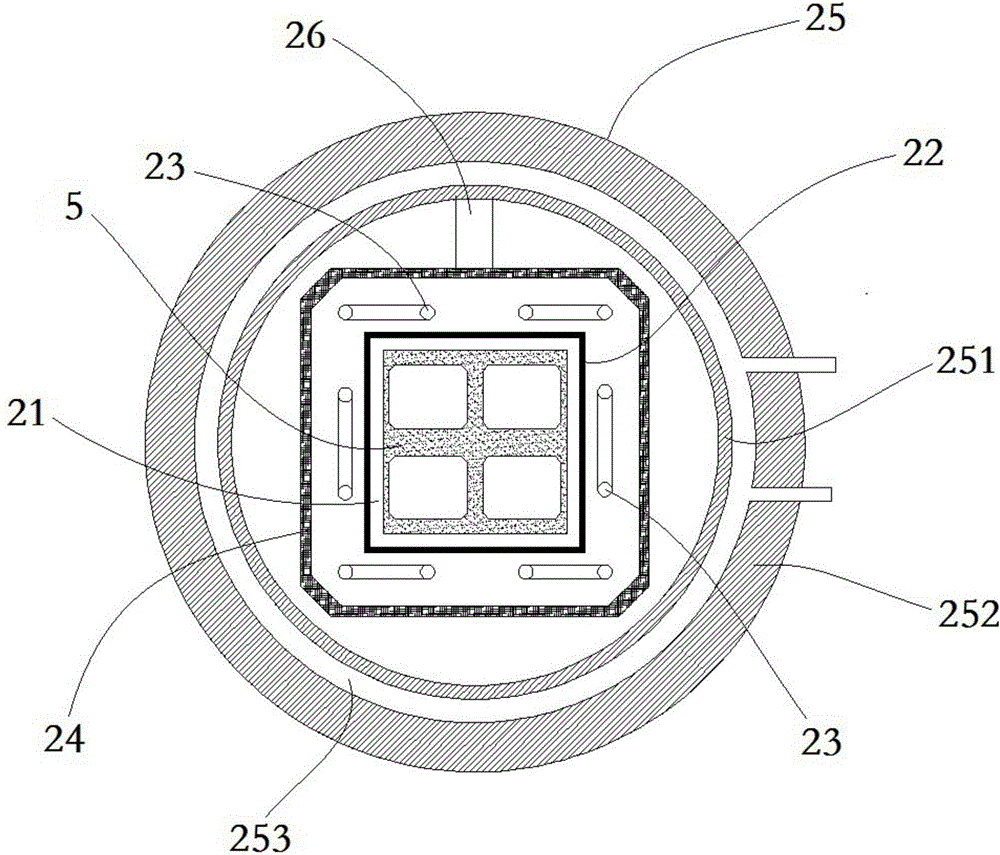

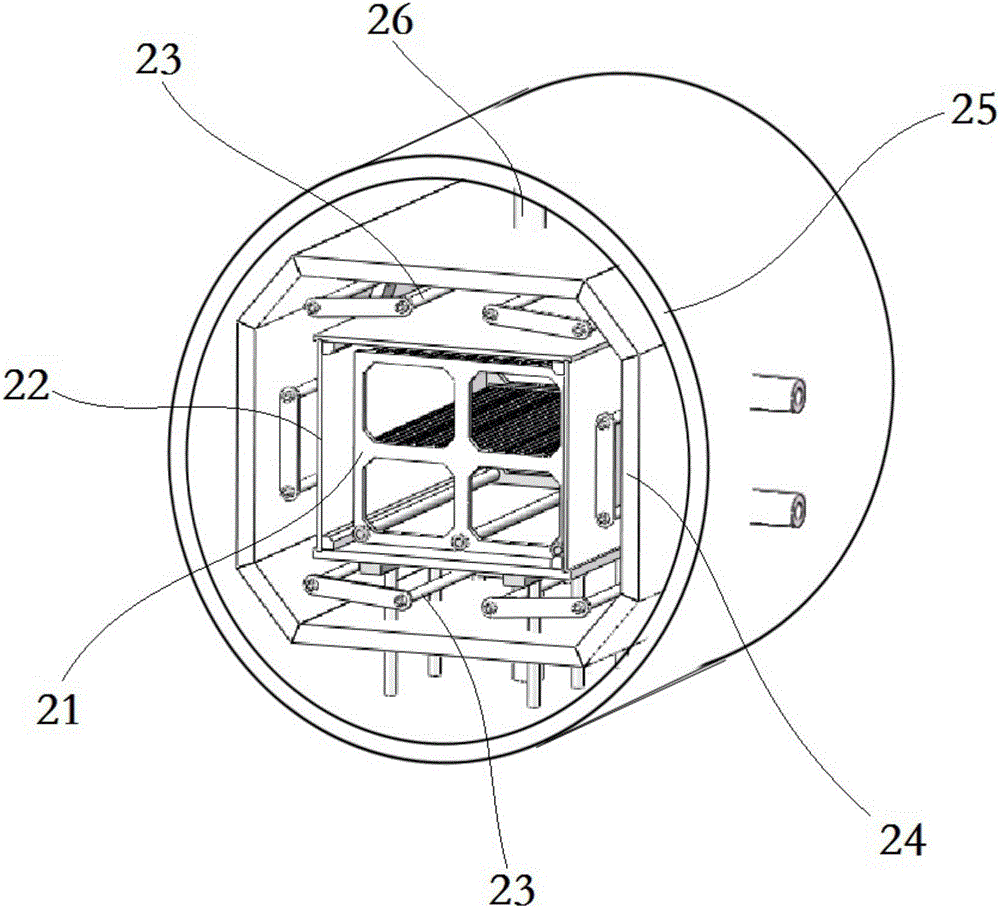

[0048] A cold fireplace for preparing graphene by the CVD method, comprising a sample inlet cabin 1, a process cabin 2, and a sample outlet cabin 3, the sample inlet cabin 1, the process cabin 2, and the sample outlet cabin are sequentially connected 3, and adjacent cabins are arranged There are flapper valves 4 for connecting or isolating adjacent compartments. The dimensions of the sample chambers 1 and 3 are Φ1500mm×1300mm, and the size of the process chamber 2 is Φ1500mm×1500mm. These three chambers are connected by two vacuum gate valves 4 with a diameter of 1500mm. Wherein, the process chamber 2 includes a reaction chamber 21 , a soaking plate 22 , a heating layer, an insulation layer 24 , and a condensation wall 25 sequentially from the center to the periphery, and the reaction chamber is used for accommodating the hanger 5 .

[0049] The heating layer adopts heating rods 23 evenly arranged on the periphery of the vapor chamber 22. Preferably, the heating rods 23 adopt ...

Embodiment 2

[0055] A continuous production method for preparing graphene by CVD method. First, vacuumize the equipment. When the pressure in the process chamber is lower than 1Pa, the carbon rod starts to be heated. Plug-in valve, the manipulator sends the hanger 5 containing the sample from the sampling cabin 1 to the process cabin 2, closes the plug-in valve 4 between the sampling cabin 1 and the process cabin 2, and starts to pass H 2 、CH 4 , Ar to carry out graphene film growth, at this time the pressure of the process cabin is about 500-1000pa, stop the ventilation after the growth is over, make the pressure <10pa, open the flapper valve 4 between the sample cabin 3 and the process cabin 2, and the manipulator will The hanger 5 with the deposited graphene sample is taken out from the process cabin 2, put into the sample delivery cabin 3, then close the plug valve 4 between the sample delivery cabin 3 and the process cabin 2, and pass argon into the sample delivery cabin 3 gas or nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com