Patents

Literature

51 results about "Injection rooms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

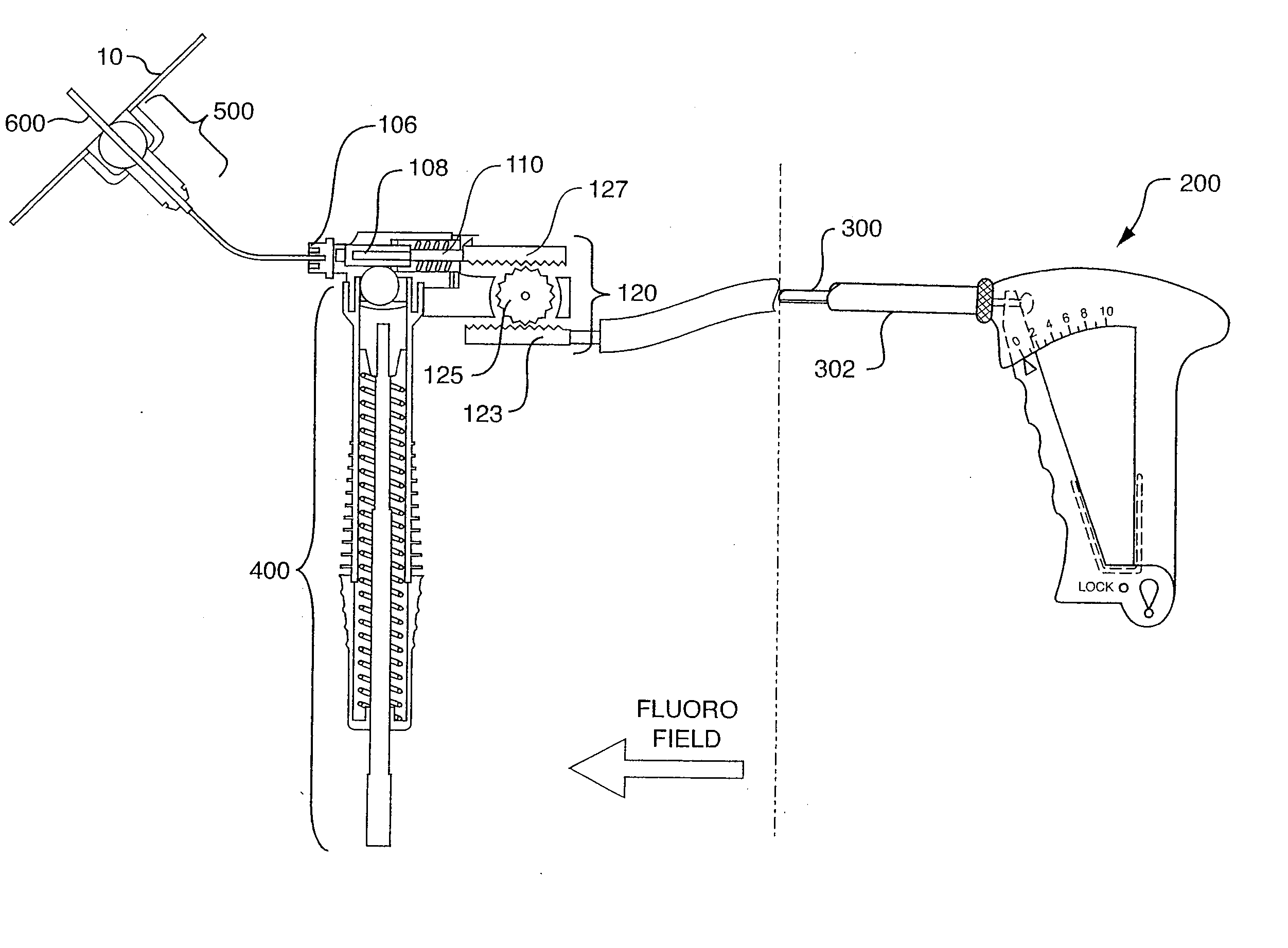

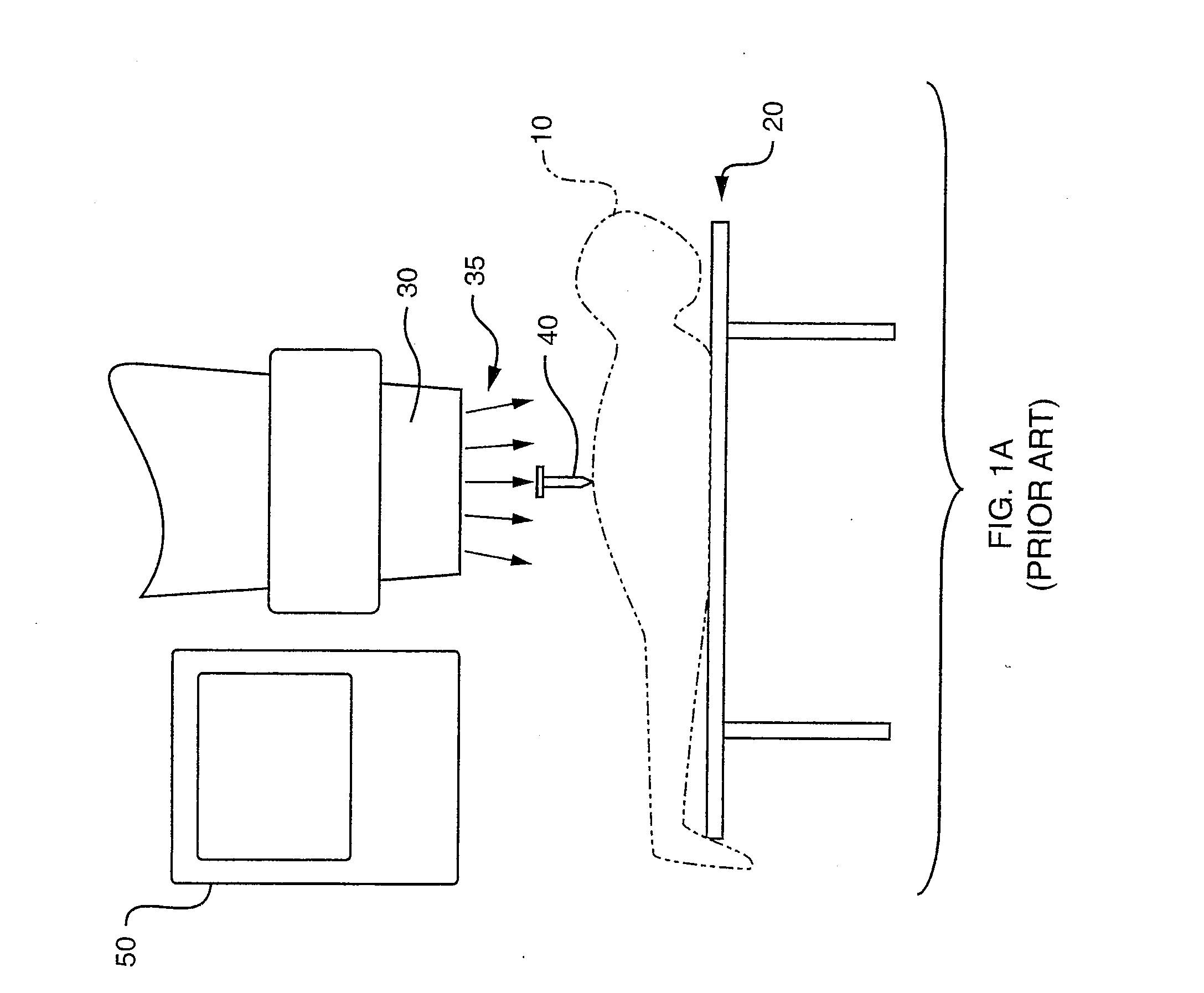

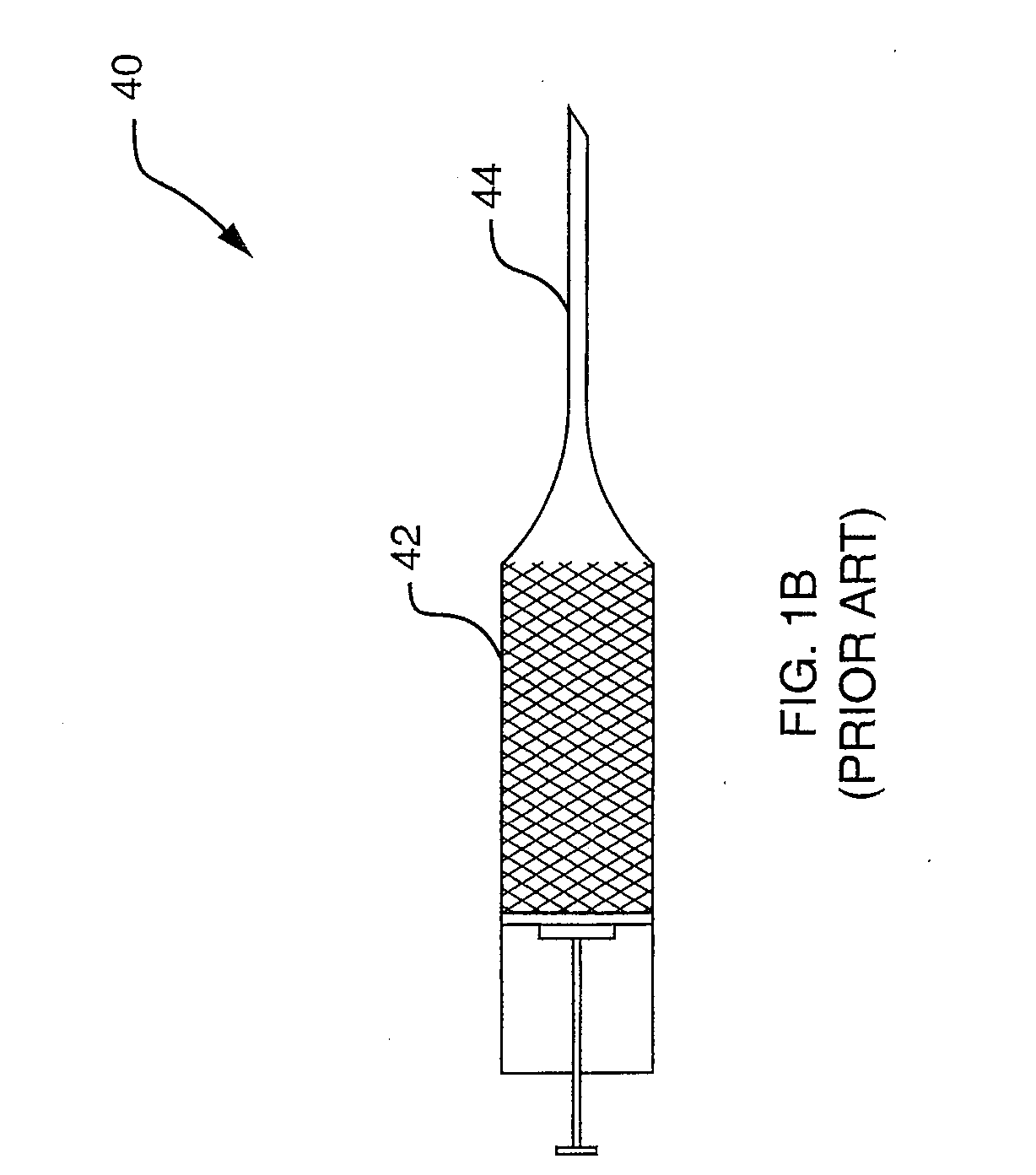

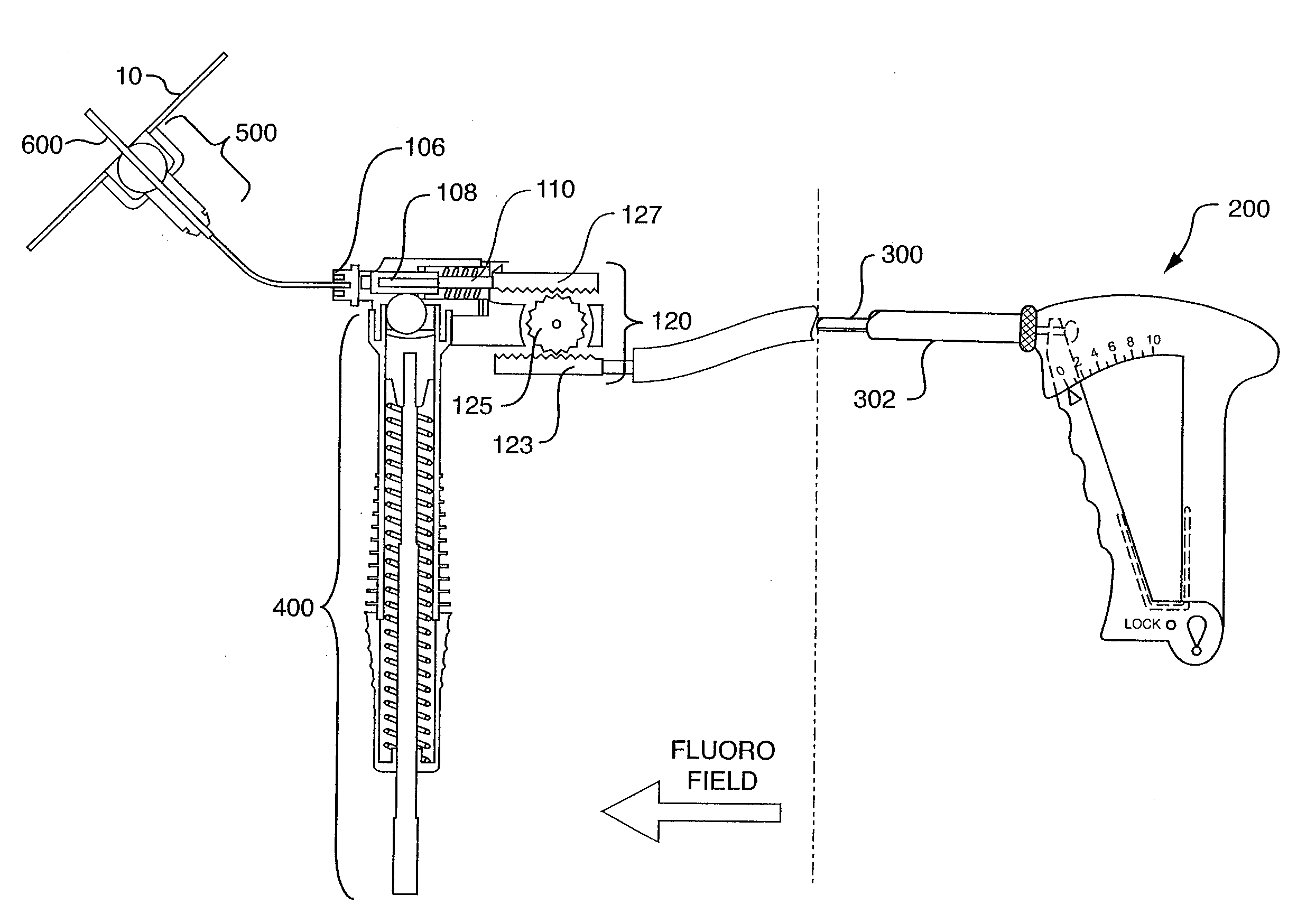

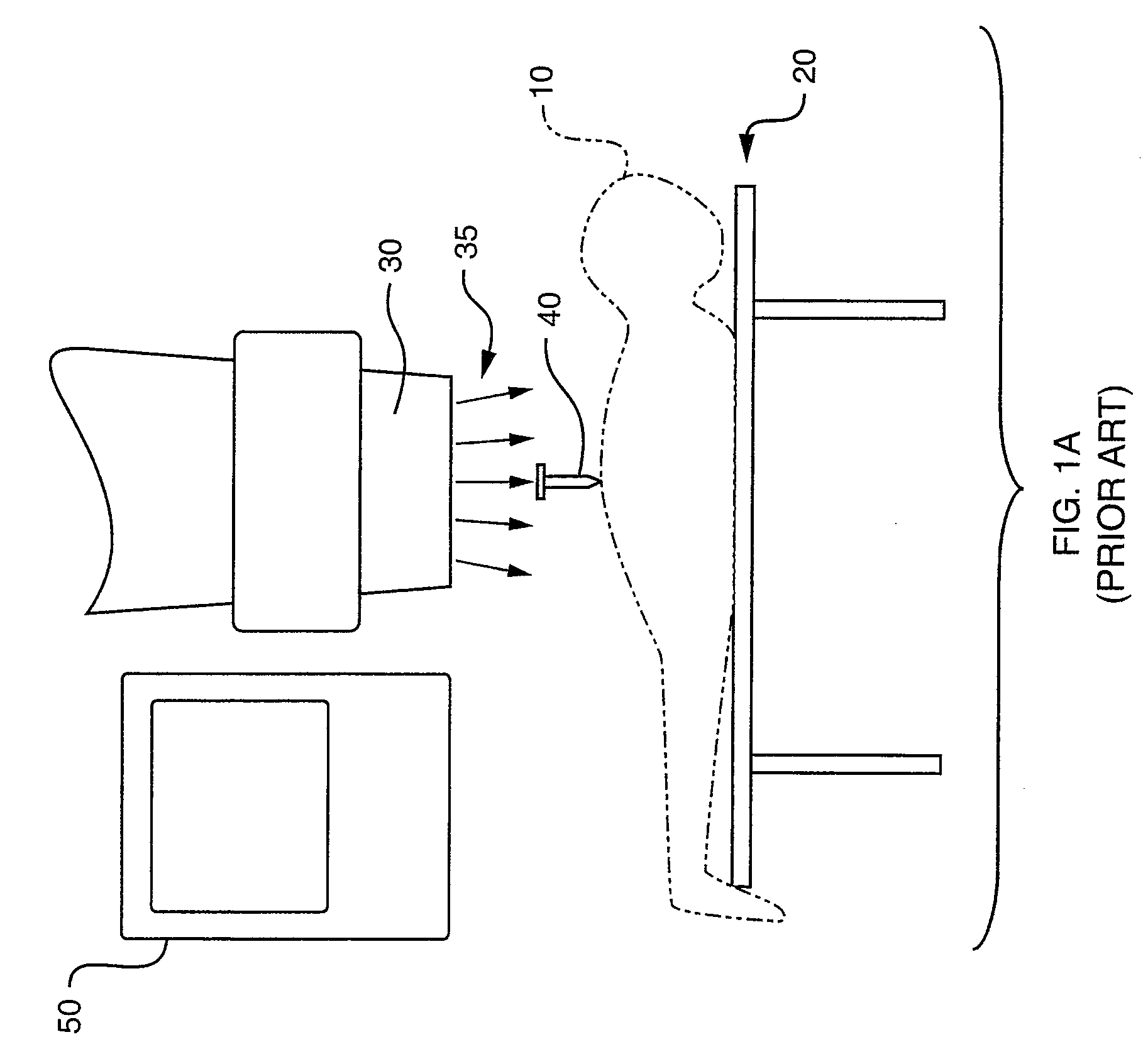

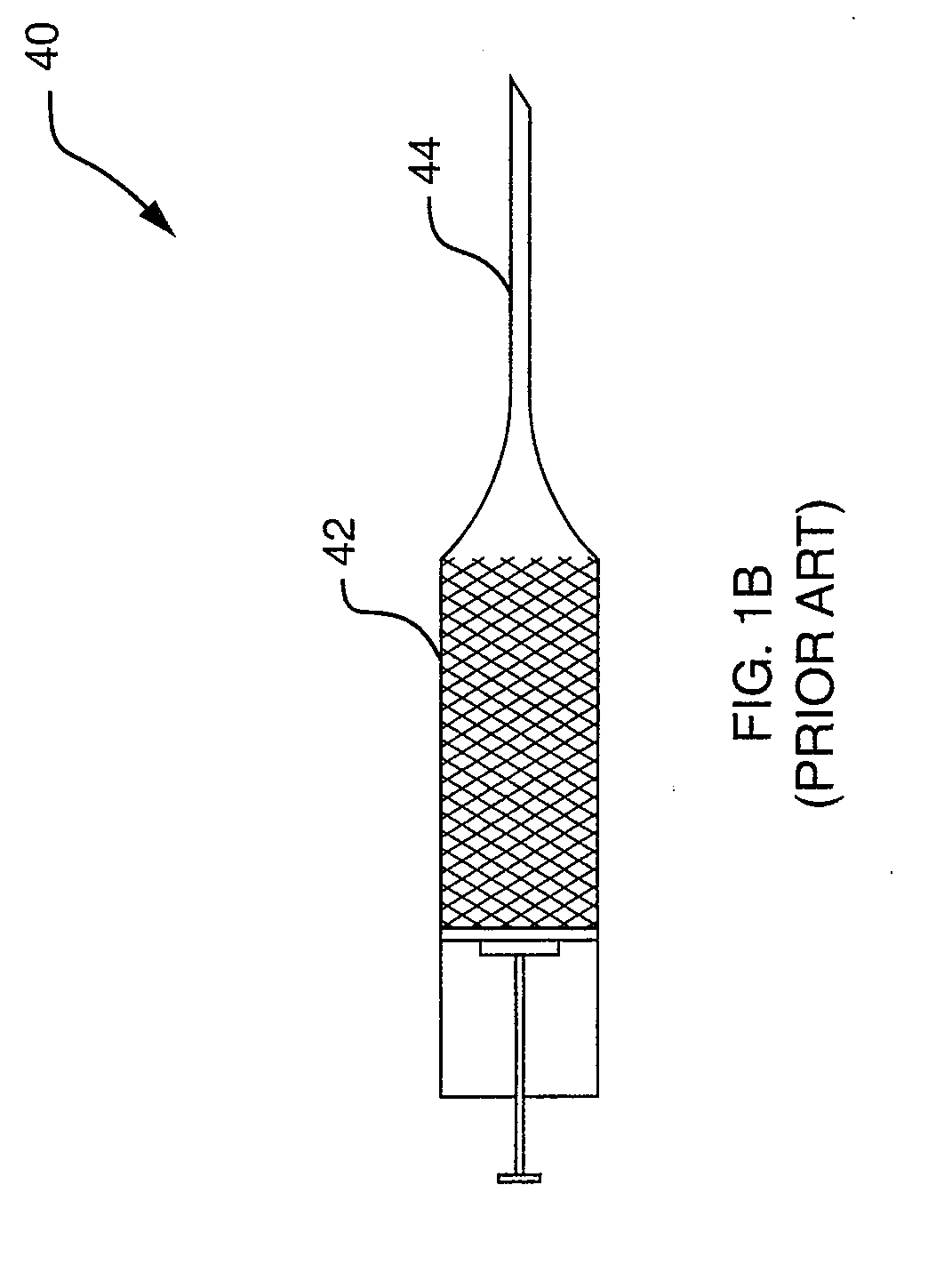

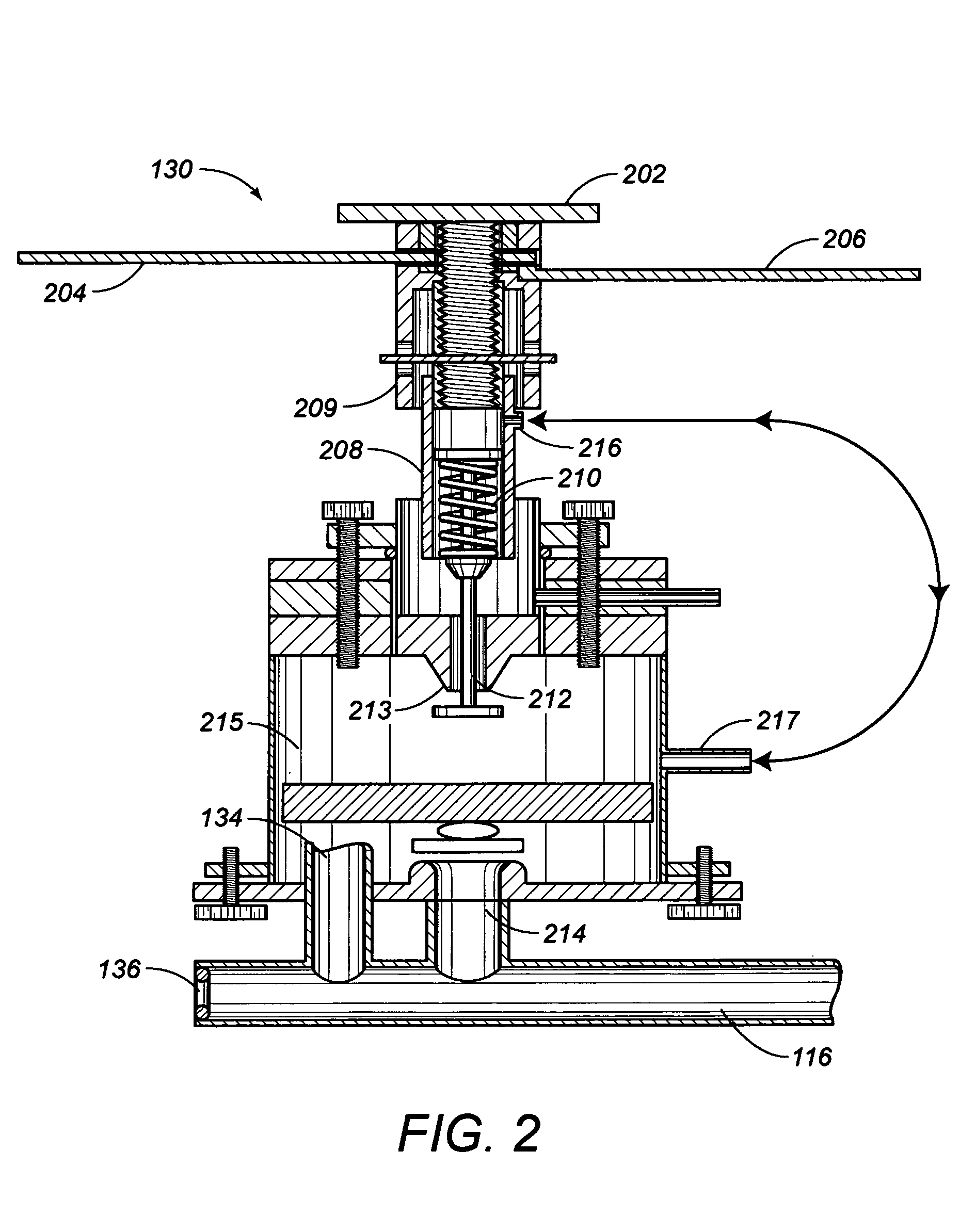

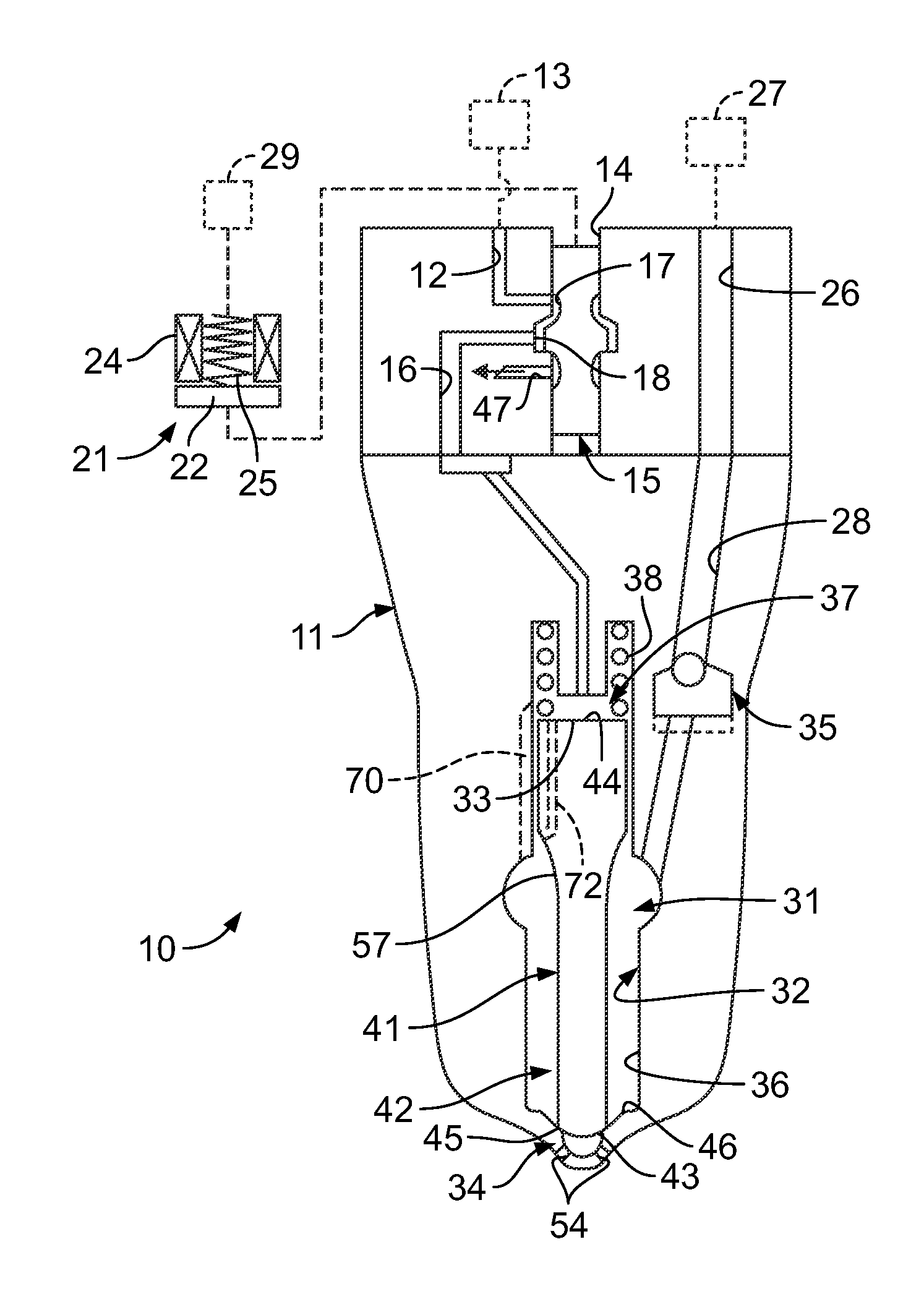

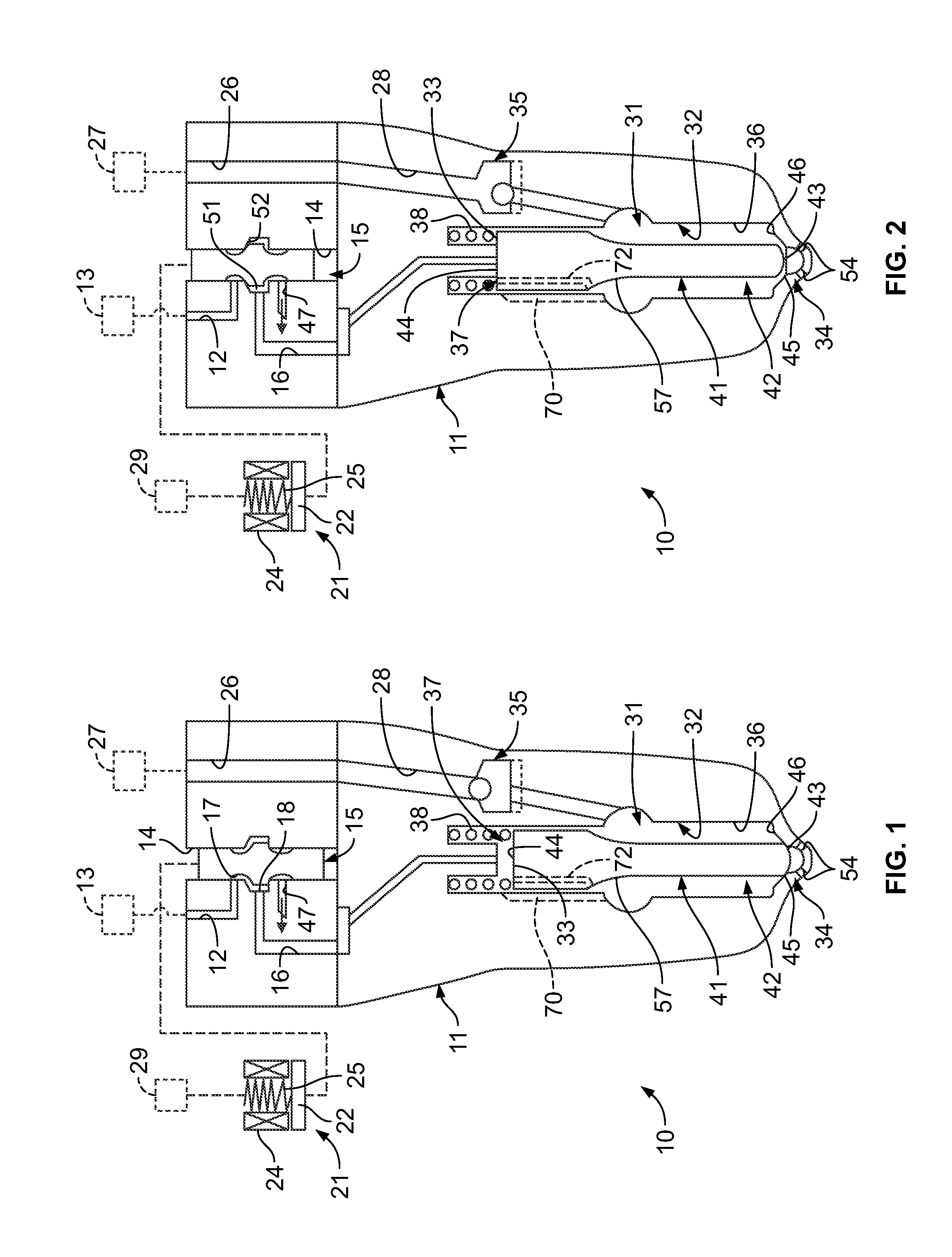

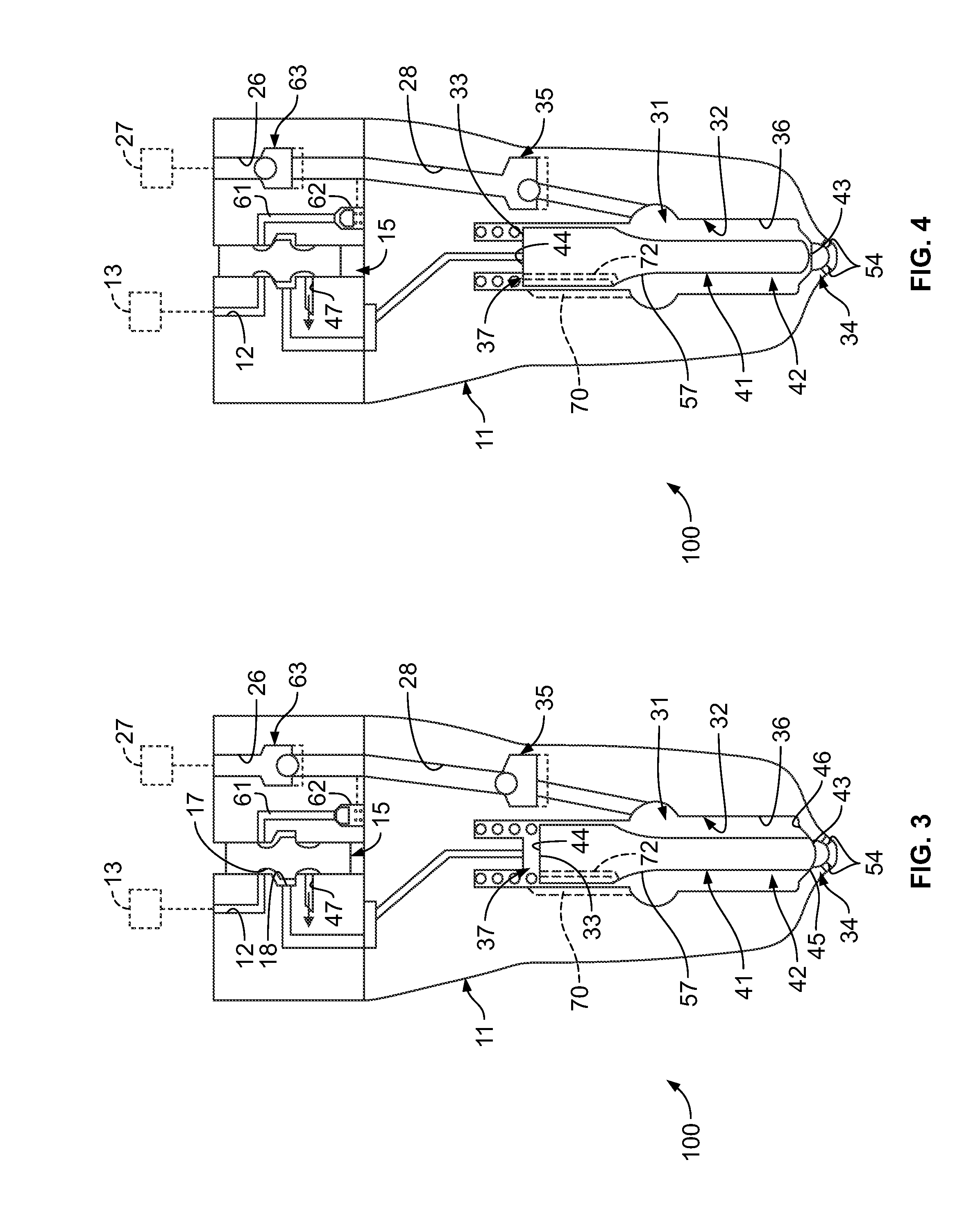

Remotely-activated vertebroplasty injection device

InactiveUS20080039856A1Eliminate the problemImprove clinician safetyJoint implantsOsteosynthesis devicesEngineeringActuator

A remotely-activated injection device for use in vertebroplasty is provided to inject a flourescent probe material into a patient. The injection device includes a pump defining an injection chamber having an exit opening; an actuator; and a cable having a first end coupled to the actuator, and a second end remotely engaging the pump. The actuator remotely controls the pump by responsive movement of the cable to thereby cause injection of a flourescent probe material from the injection chamber of the pump through the exit opening to the patient.

Owner:DEPUY SPINE INC (US) +1

Remotely-activated vertebroplasty injection device

ActiveUS20090270872A1Eliminate the problemImprove securityJoint implantsSuction devicesEngineeringActuator

A remotely-activated injection device for use in vertebroplasty is provided to inject a flourescent probe material into a patient. The injection device includes a pump defining an injection chamber having an exit opening; an actuator; and a cable having a first end coupled to the actuator, and a second end remotely engaging the pump. The actuator remotely controls the pump by responsive movement of the cable to thereby cause injection of a flourescent probe material from the injection chamber of the pump through the exit opening to the patient.

Owner:DEPUY SYNTHES PROD INC +1

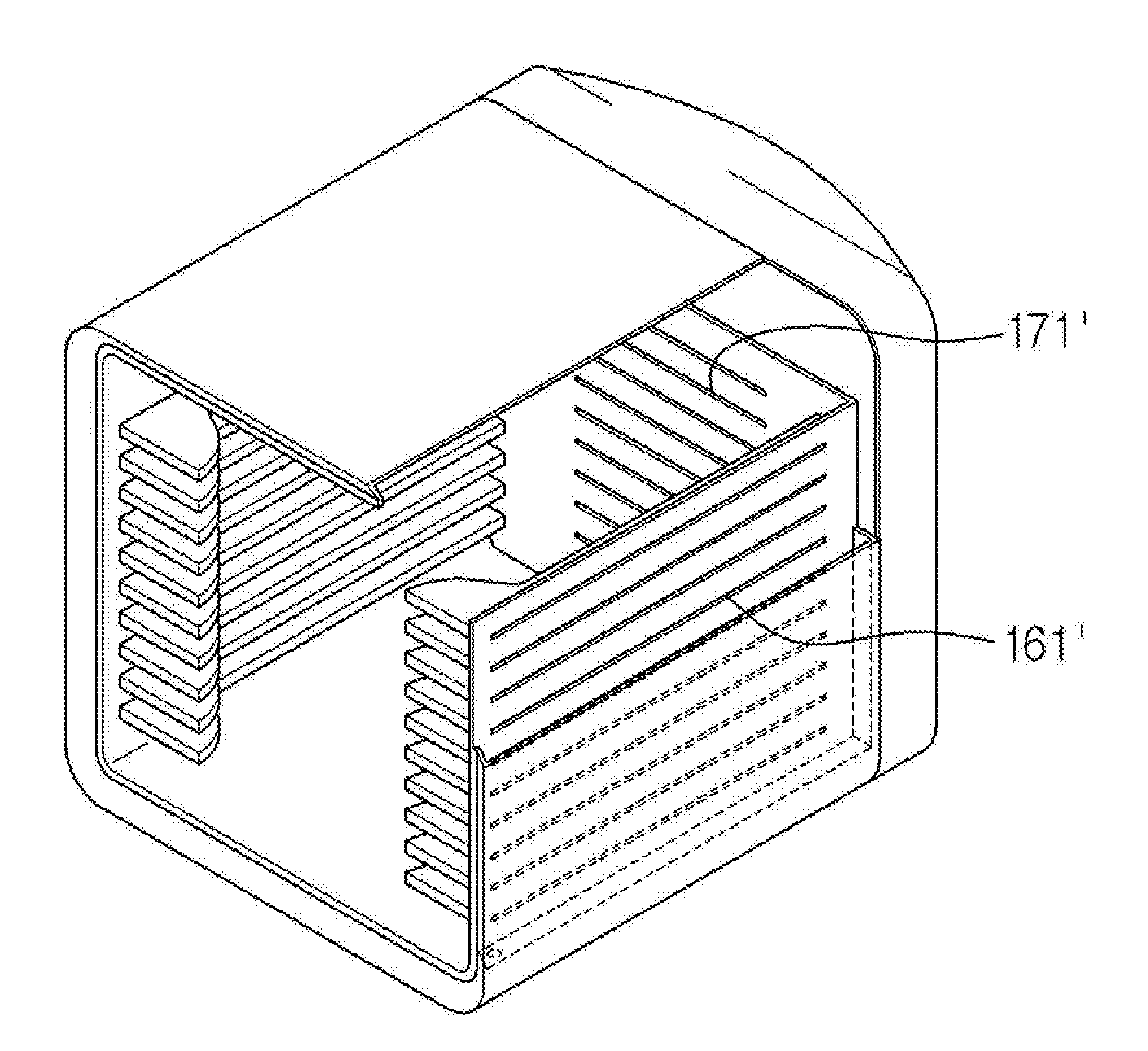

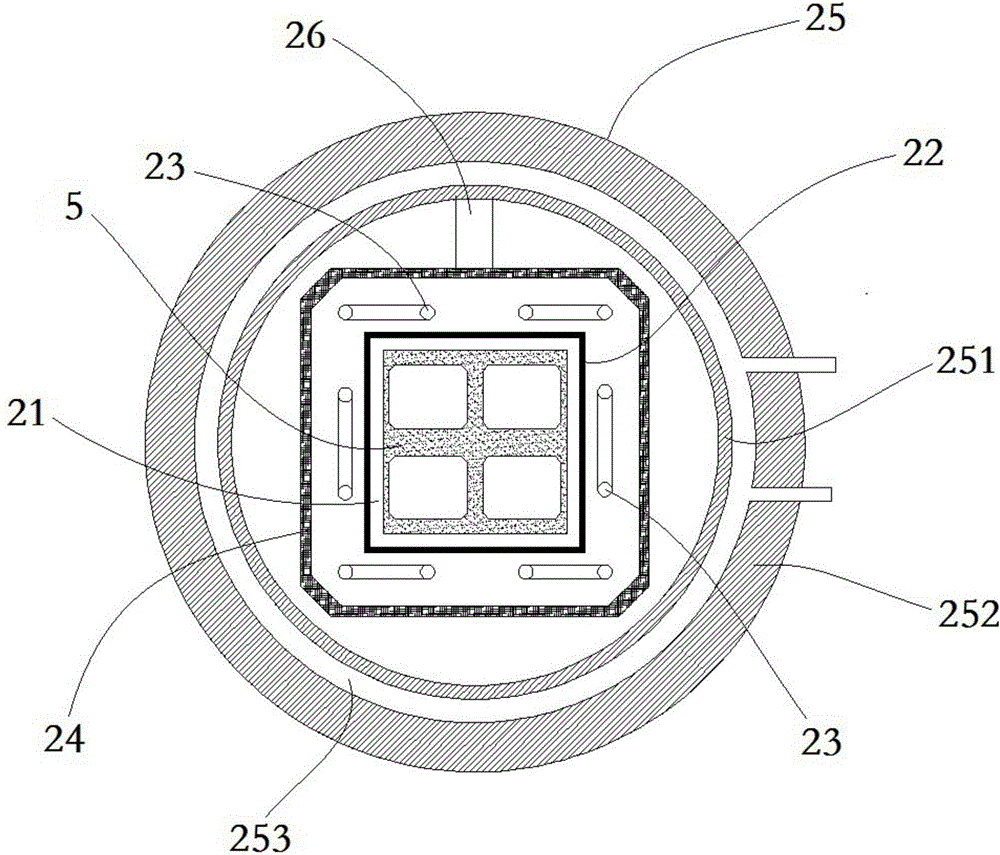

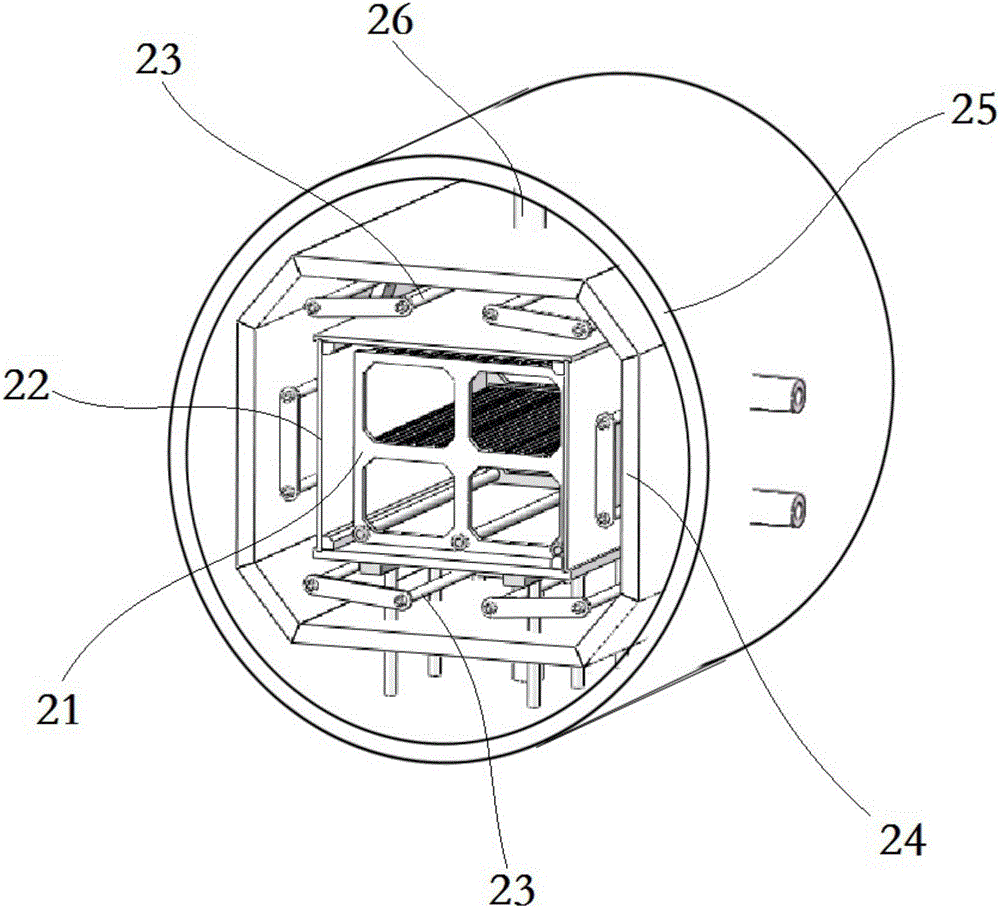

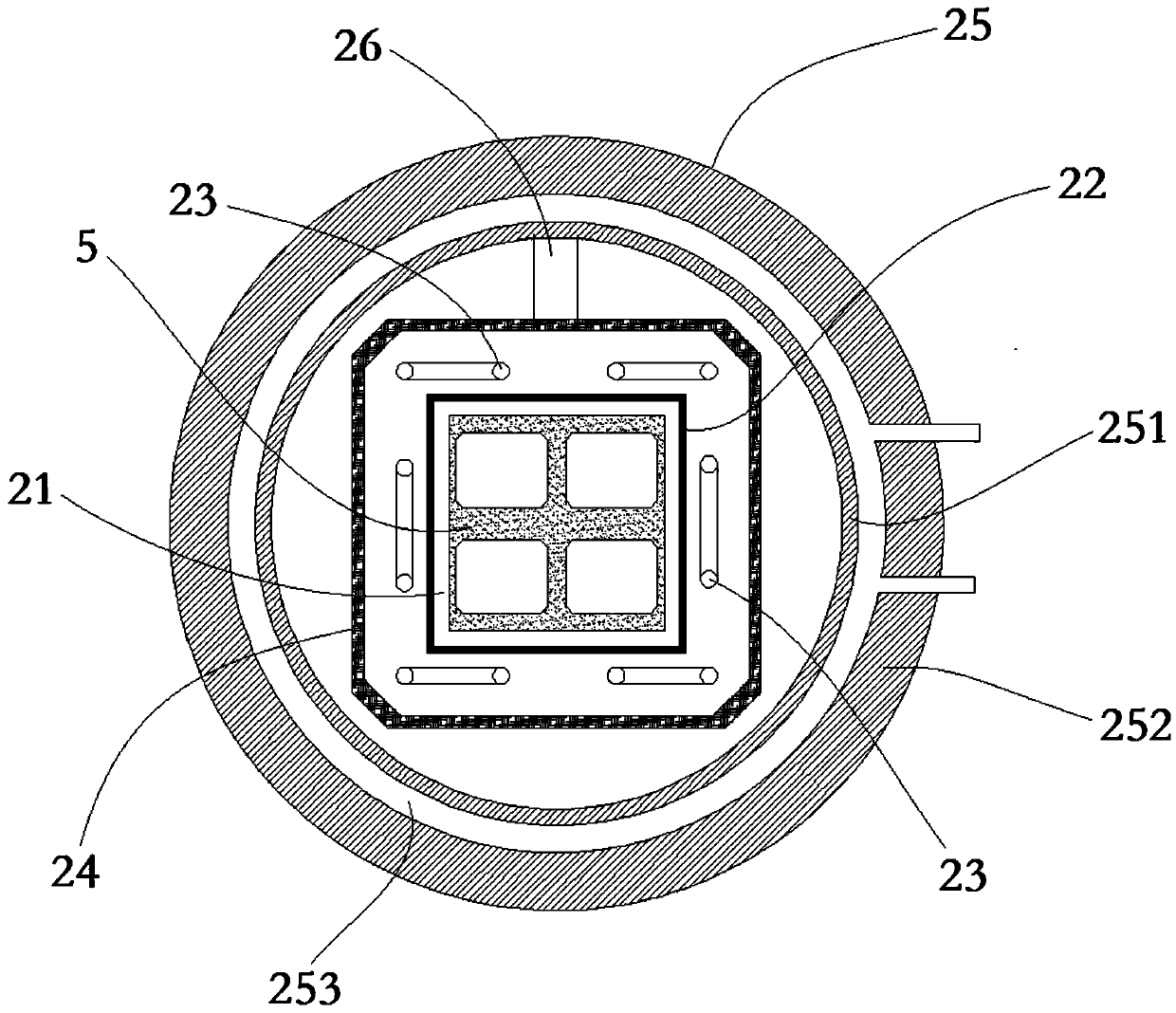

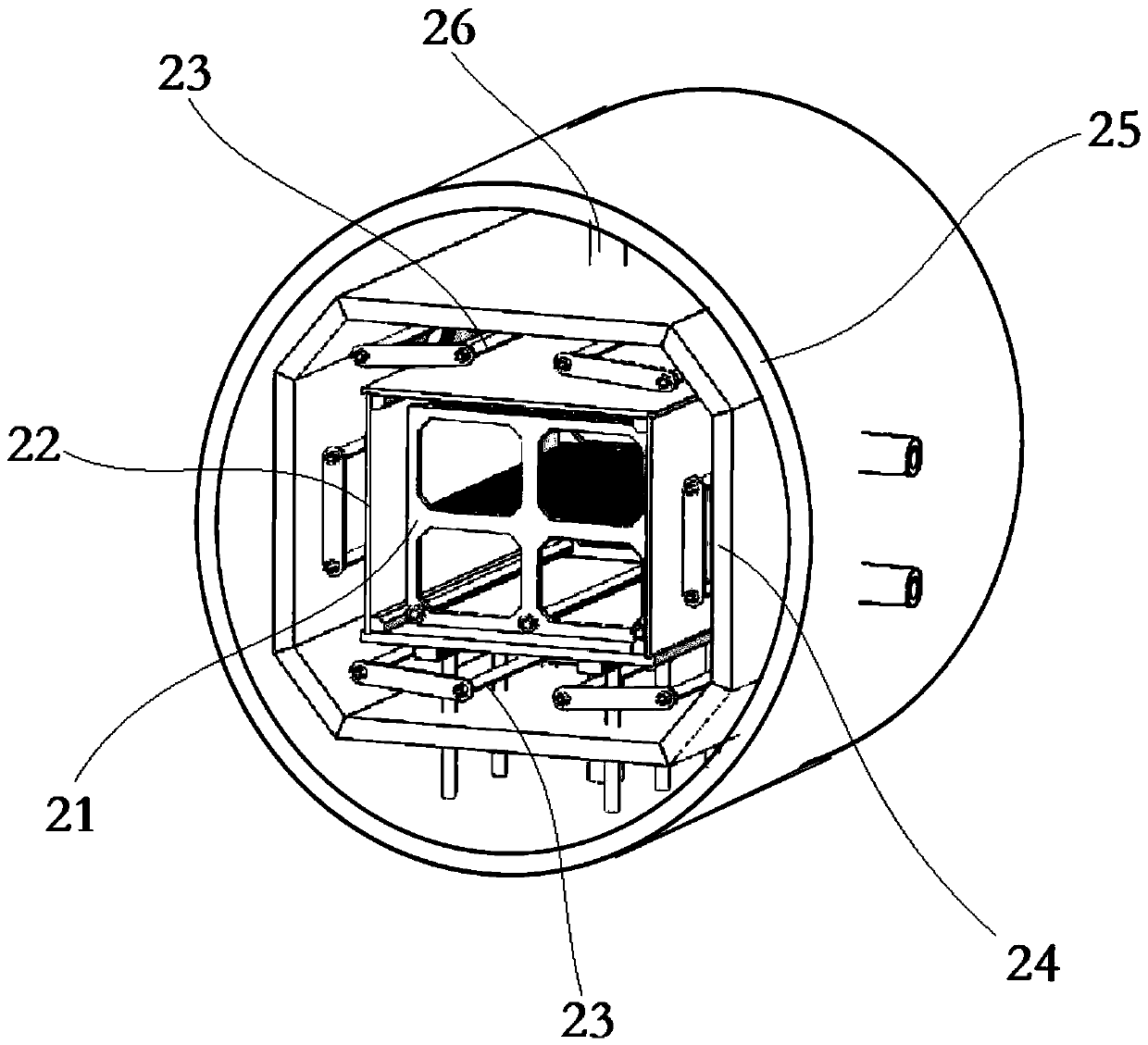

Wafer storage container

ActiveUS20160284580A1Efficient removalSmooth exhaustSemiconductor/solid-state device manufacturingEngineeringHolding room

The present invention relates to a wafer storage container, more particularly, relates to a wafer storage container wherein the space of the wafer storage container is divided into the spaces, namely a storage room, a gas injection room, and a gas exhausting room, which are independent and separate from each other, so when the wafer storage container is transported to the load port and being coupled therewith, the purge gas is injected / exhausted through the separating walls inside the storage room, thereby efficiently removing the remaining fumes on the surface of the wafer.

Owner:PICO & TERA CO LTD +1

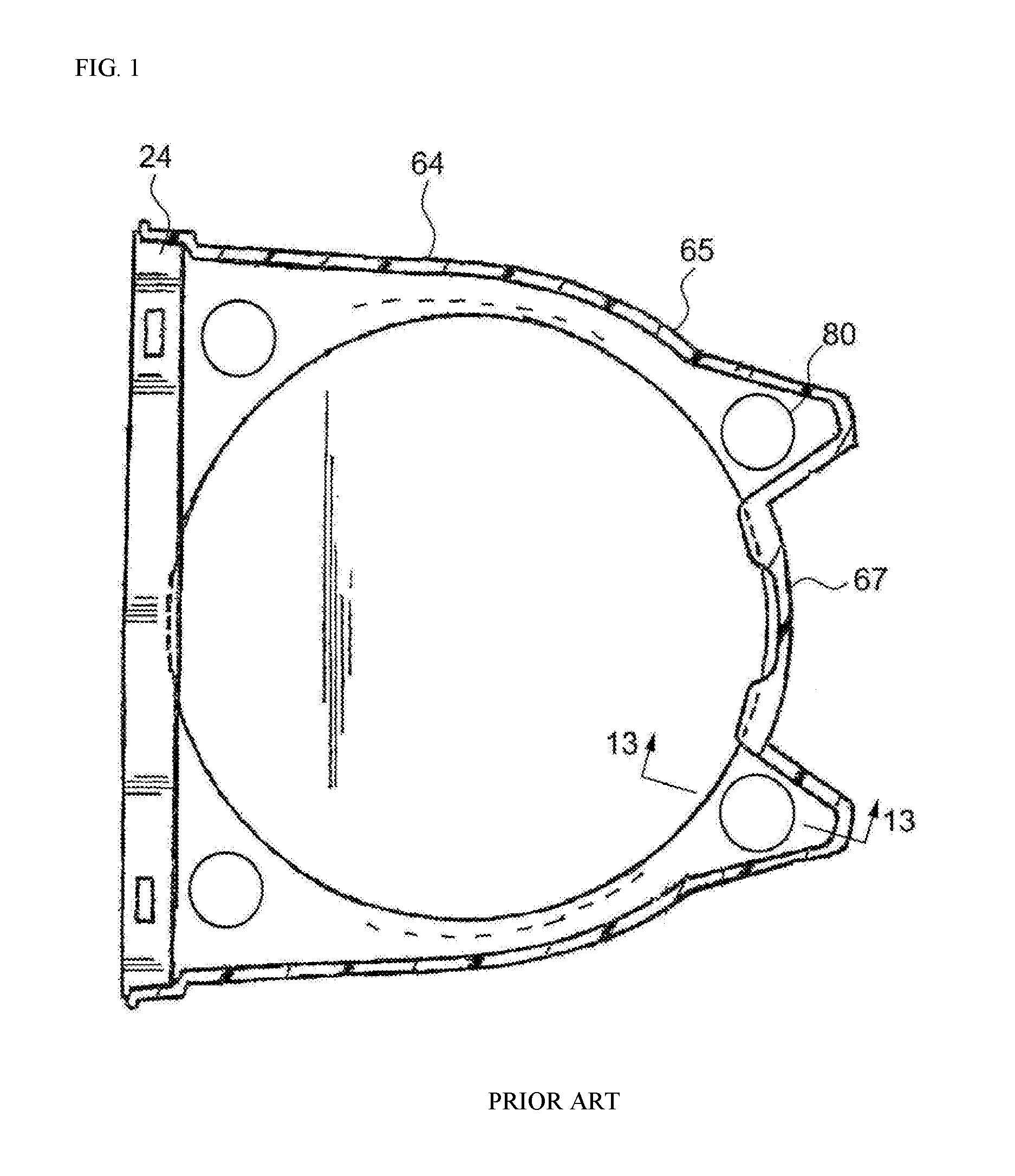

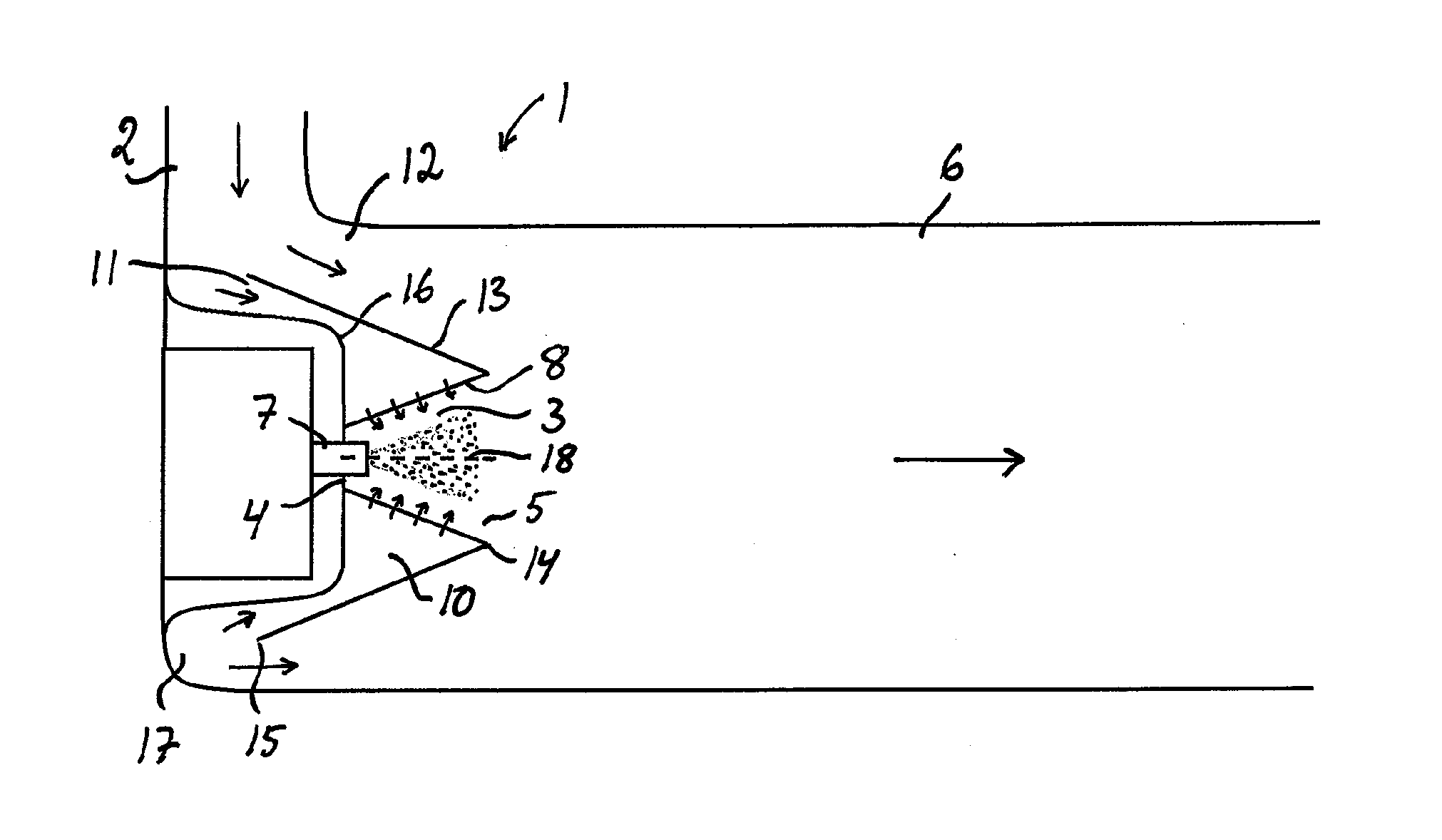

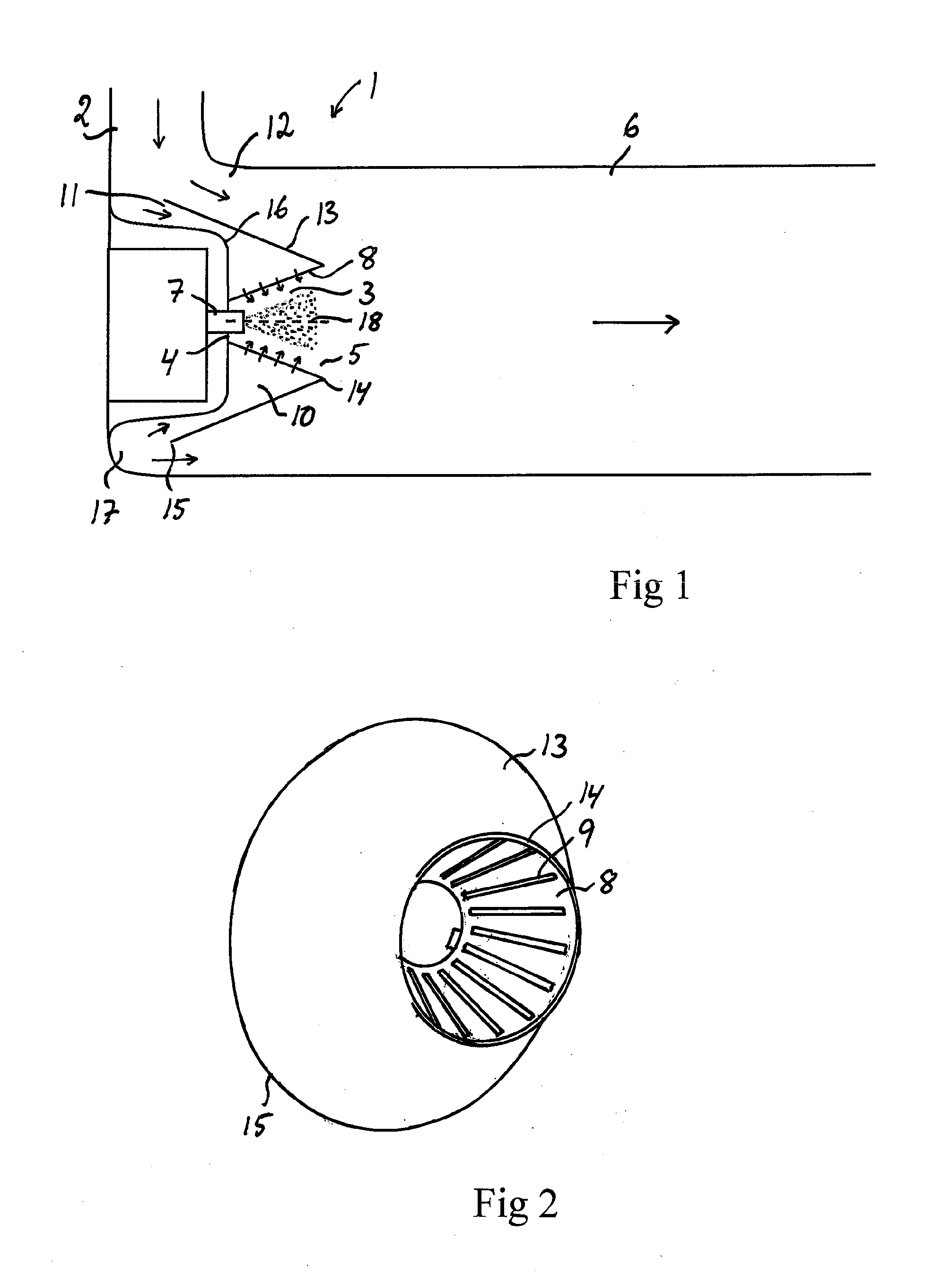

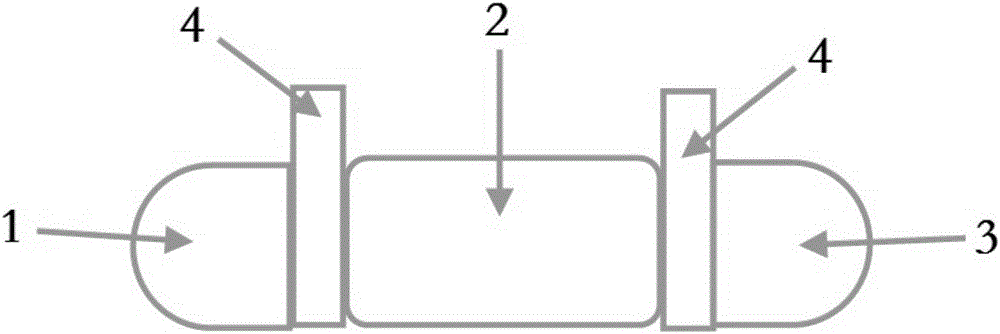

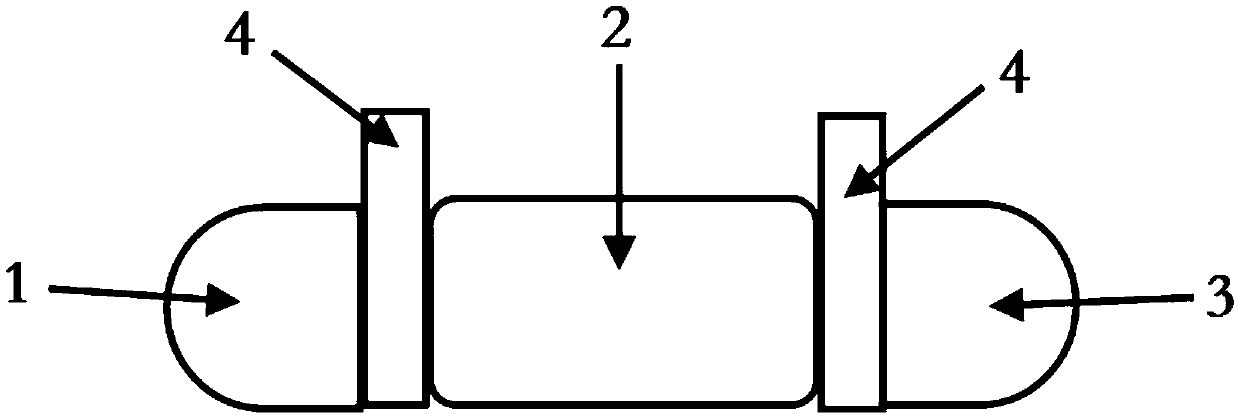

Arrangement for introducing a liquid medium into exhaust gases from a combustion engine

ActiveUS20130152558A1Reduce riskContribution can be suppressedInternal combustion piston enginesFlow mixersLiquid mediumCombustion

Arrangement for introducing a liquid medium into exhaust gases from a combustion engine: an injector for injecting the liquid medium into an injection chamber (3), a casing (8) which surrounds the injection chamber, a mixing duct (6), a gathering chamber (10) which surrounds the casing and is connected to the injection chamber via throughflow apertures of the casing, and a bypass duct (12) for leading exhaust gases into the mixing duct without passing through the gathering chamber and the injection chamber. The inlet (11) of the gathering chamber diverts a portion of the exhaust gases to flow into the gathering chamber, and then into the injection chamber via the throughflow apertures, and thereafter into the mixing duct, while the bypass duct leads another portion of the exhaust gases into the mixing duct in order to be mixed there with the diverted exhaust gases.

Owner:SCANIA CV AB

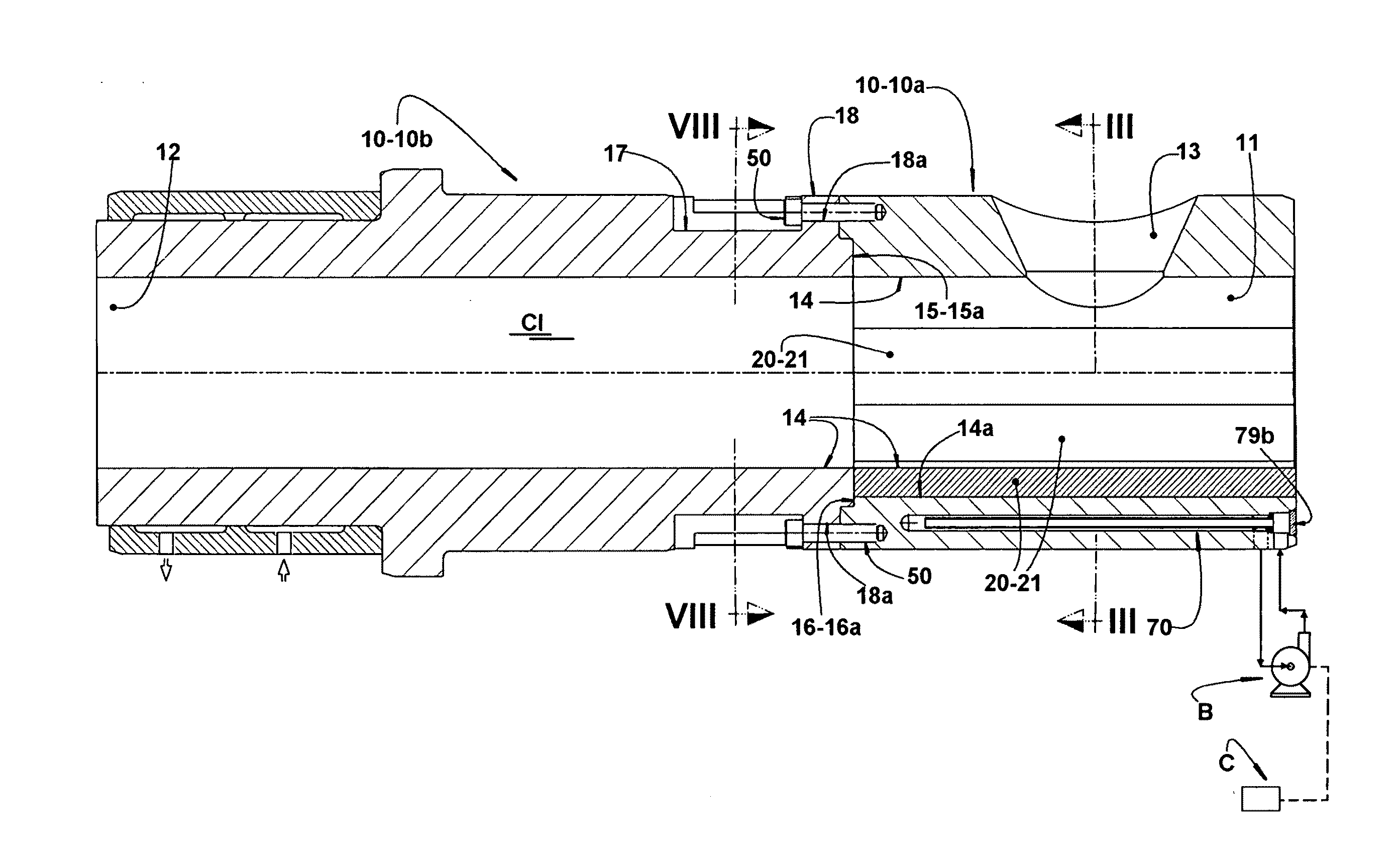

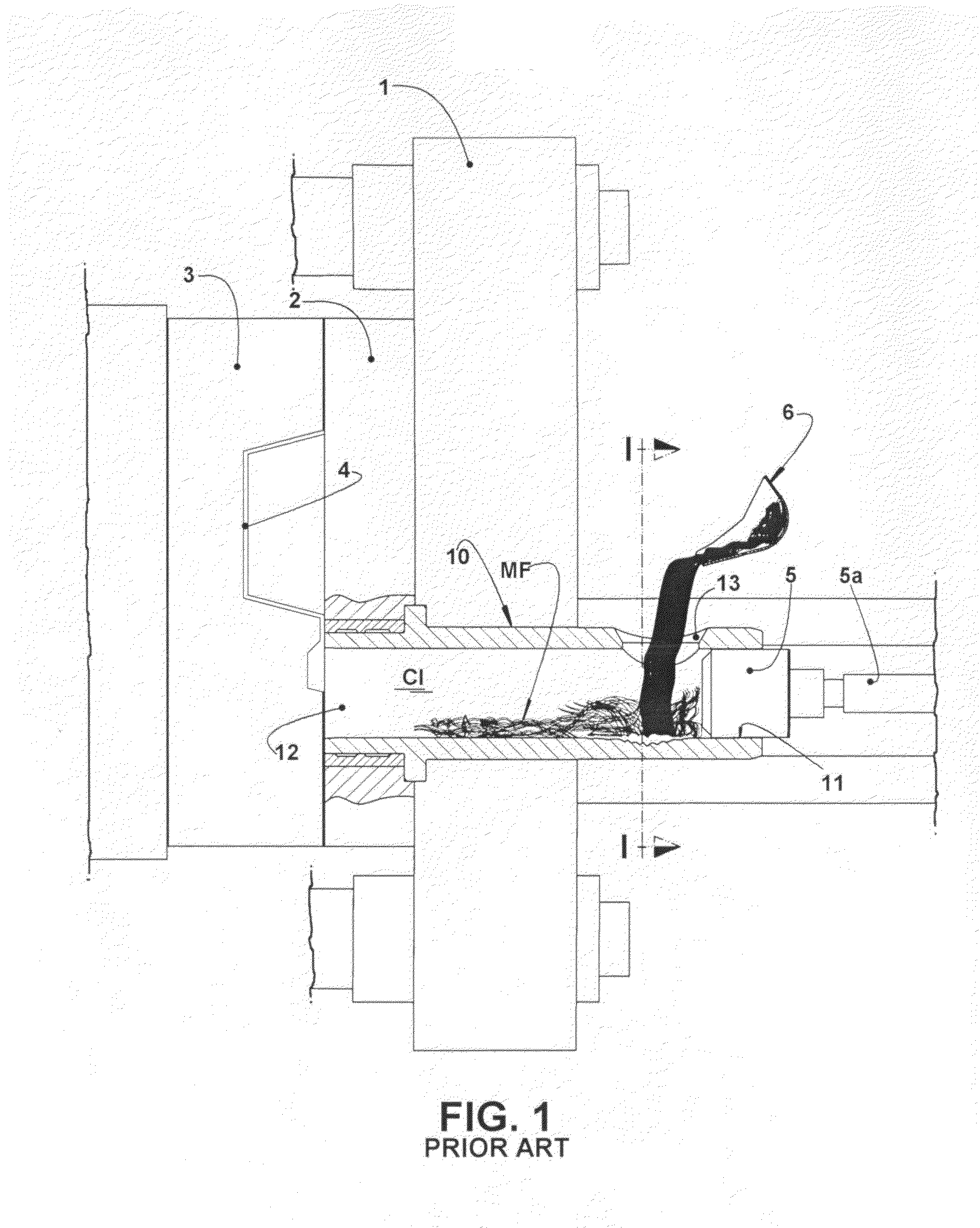

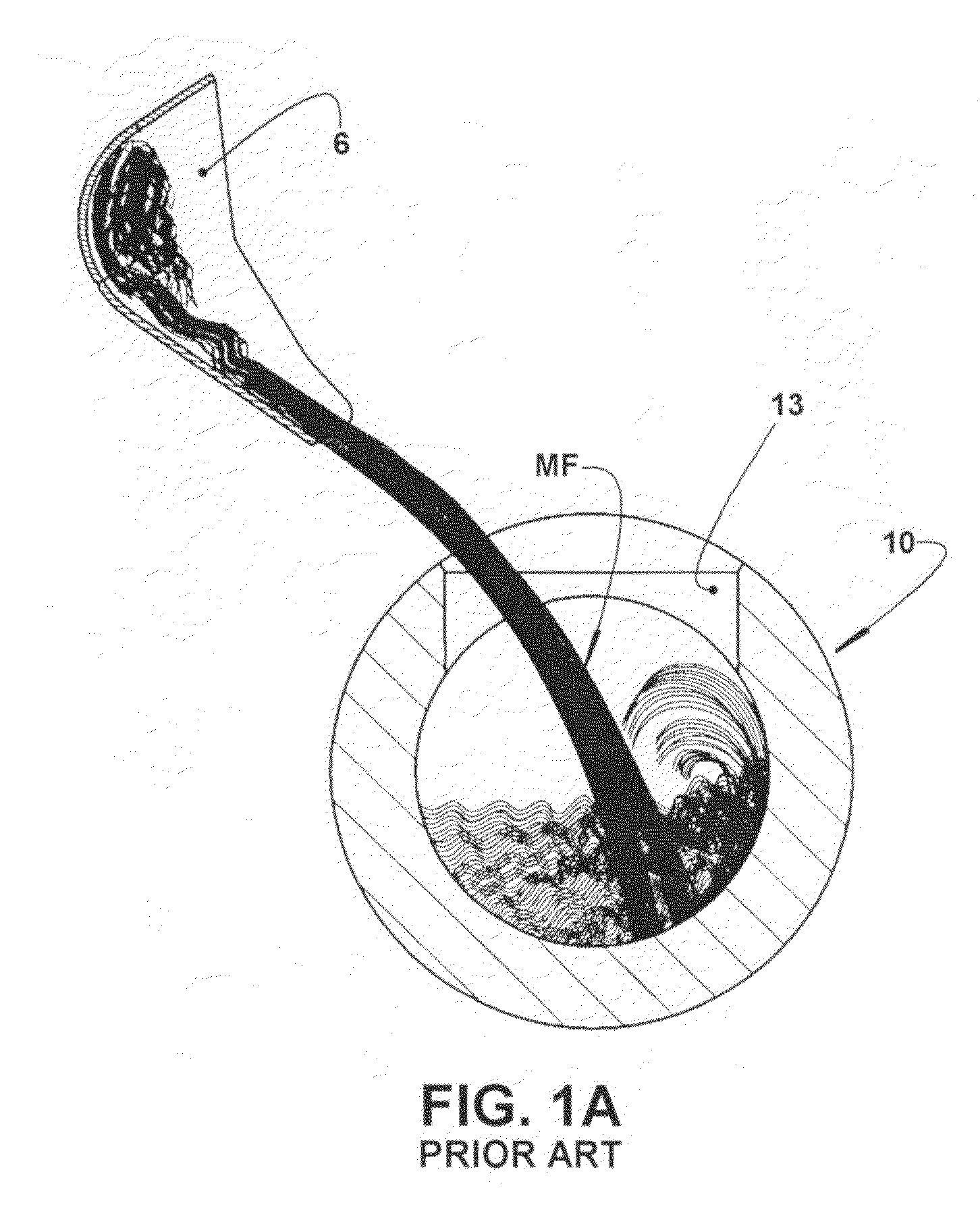

Injection chamber for a metal injection machine

InactiveUS20110011900A1Cooling becomes necessaryNegative consequences on the quality of the injected end-pieceMelt-holding vesselsLiquid flow controllersMetallurgyPiston

The injection chamber (CI) includes a tubular body formed by a supply portion, having a radial supply window to receive a charge of molten metal (MF) and in which is incorporated an injection portion provided with an outlet end opened to the interior of a molding cavity. A piston is provided to be displaced in the interior of the tubular body to inject the molten metal (MF) in the molding cavity. The supply portion has its inner region, which receives the pouring impact of the charge of molten metal (MF), lined by an insert formed in a high melting point material and presenting an inner contour in the form of a circle arc coinciding with that of the supply and injection portions.

Owner:W FISCHER TECNICA

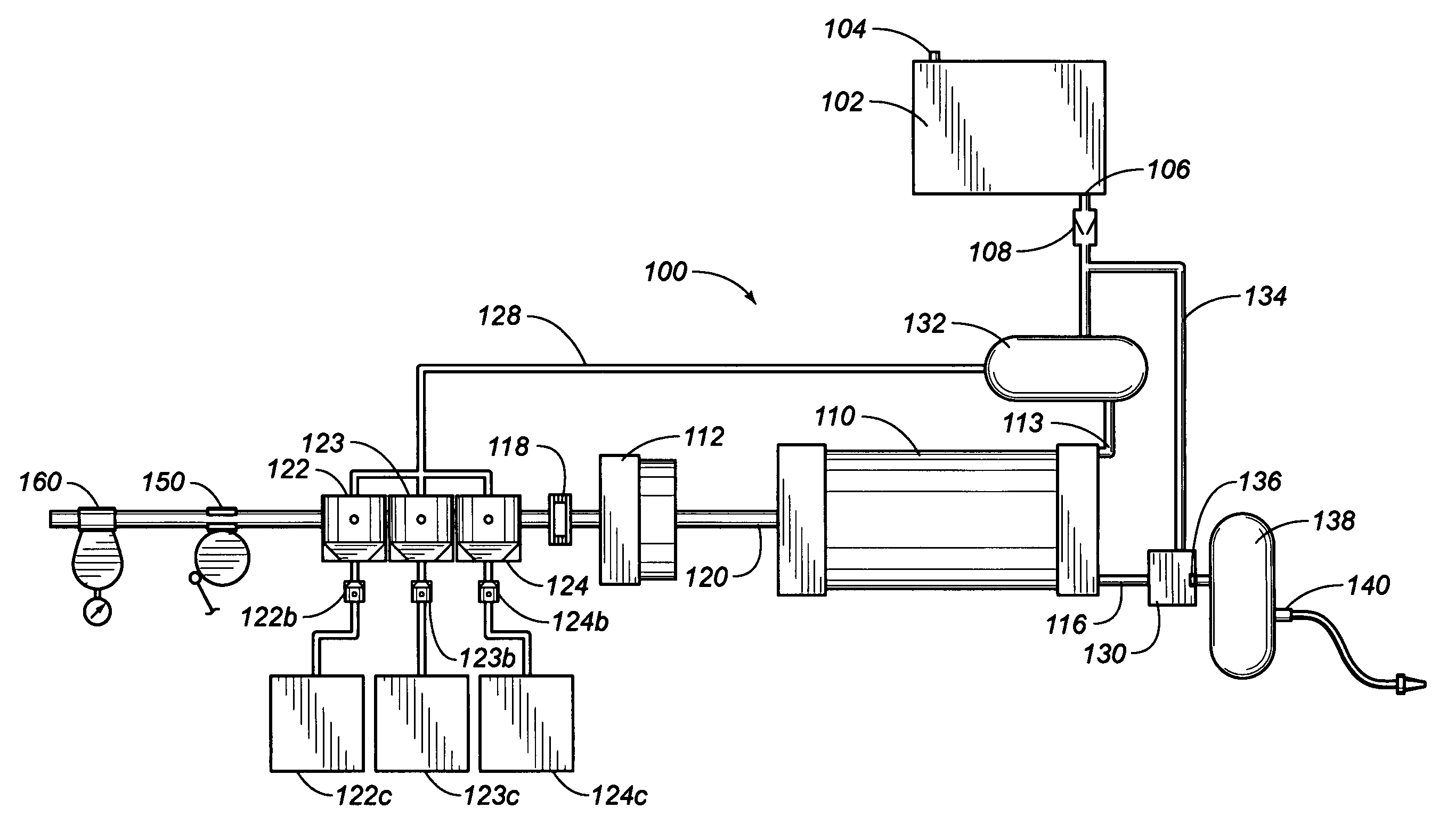

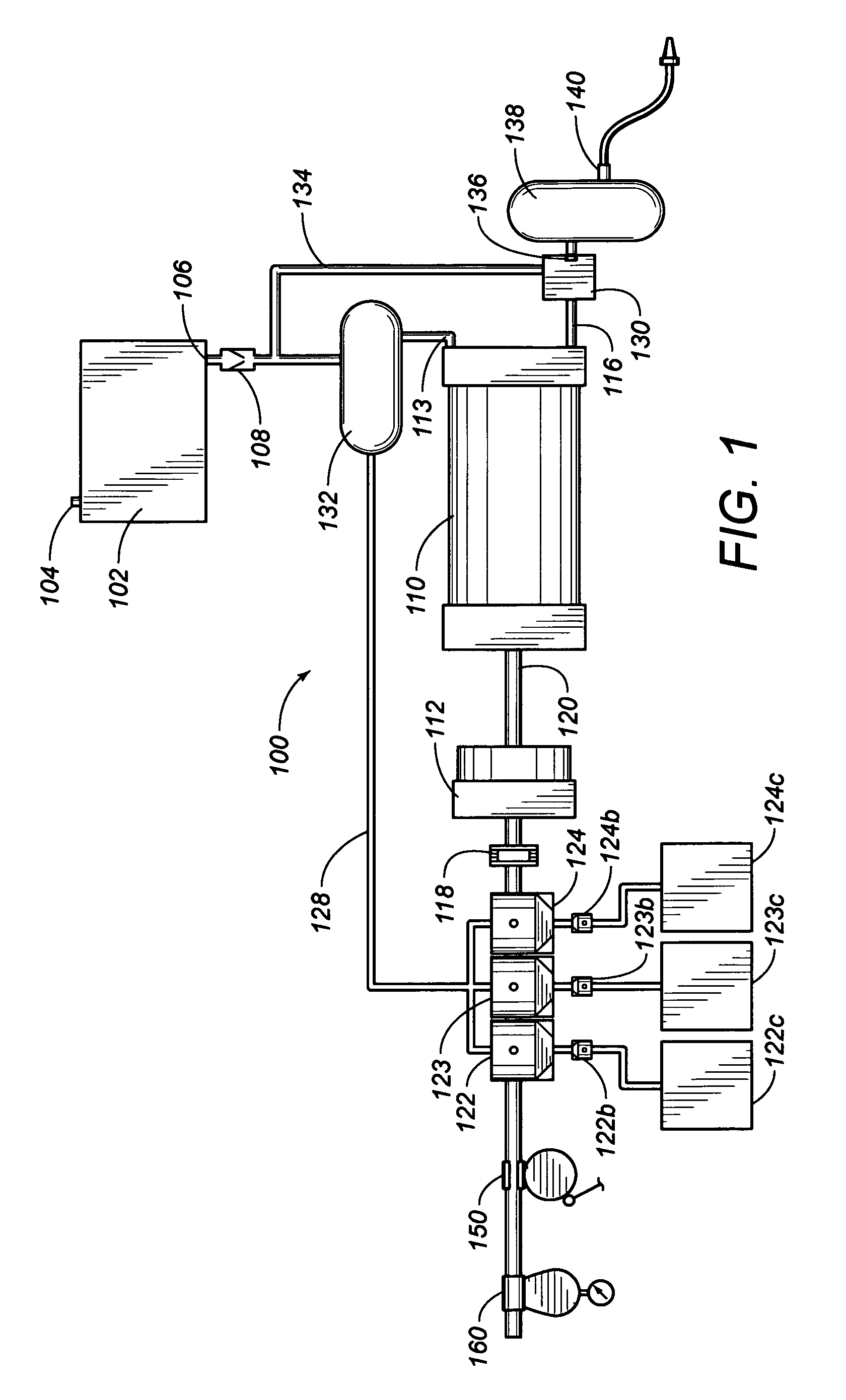

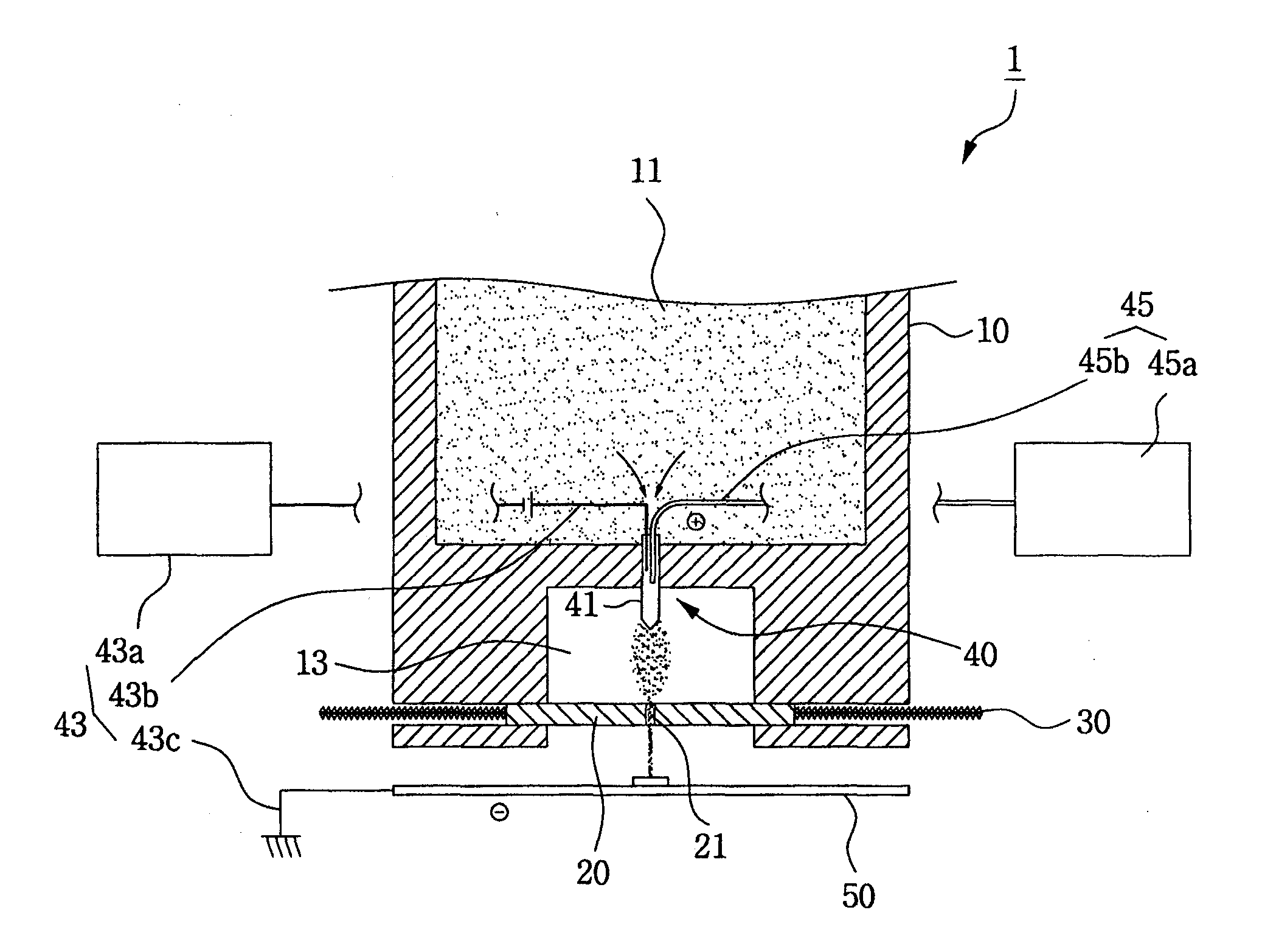

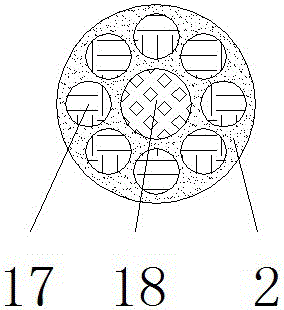

Injection spraying system

InactiveUS6899282B1Improve handlingEasy CalibrationMixer accessoriesFire rescueClutchInjection rooms

An injection spraying system for mixing additives in controlled amounts to water for spraying, which improves handling and calibrating of the concentration of the mixture. The system includes a water tank, mixing globe, pump device, unloader chamber and a worm reduction element for reducing pumping of one gallon of water into one revolution of a drive shaft. The shaft extends through a clutch device and a plurality of injection chambers. The injection chambers supply and meter the amount of additives injected. Rotation of the shaft through the injection chambers loads a set amount of additives for suction into a mixing globe. The unloader chamber controls the spraying cycle and by-pass cycle of fluid flow through the system. The present invention provides a versatile injection spraying system for multiple tasks. The types and amounts of additives sprayed can be easily adjusted without requiring adjustments to sensitive metering or measuring devices.

Owner:HILL RAYMOND G

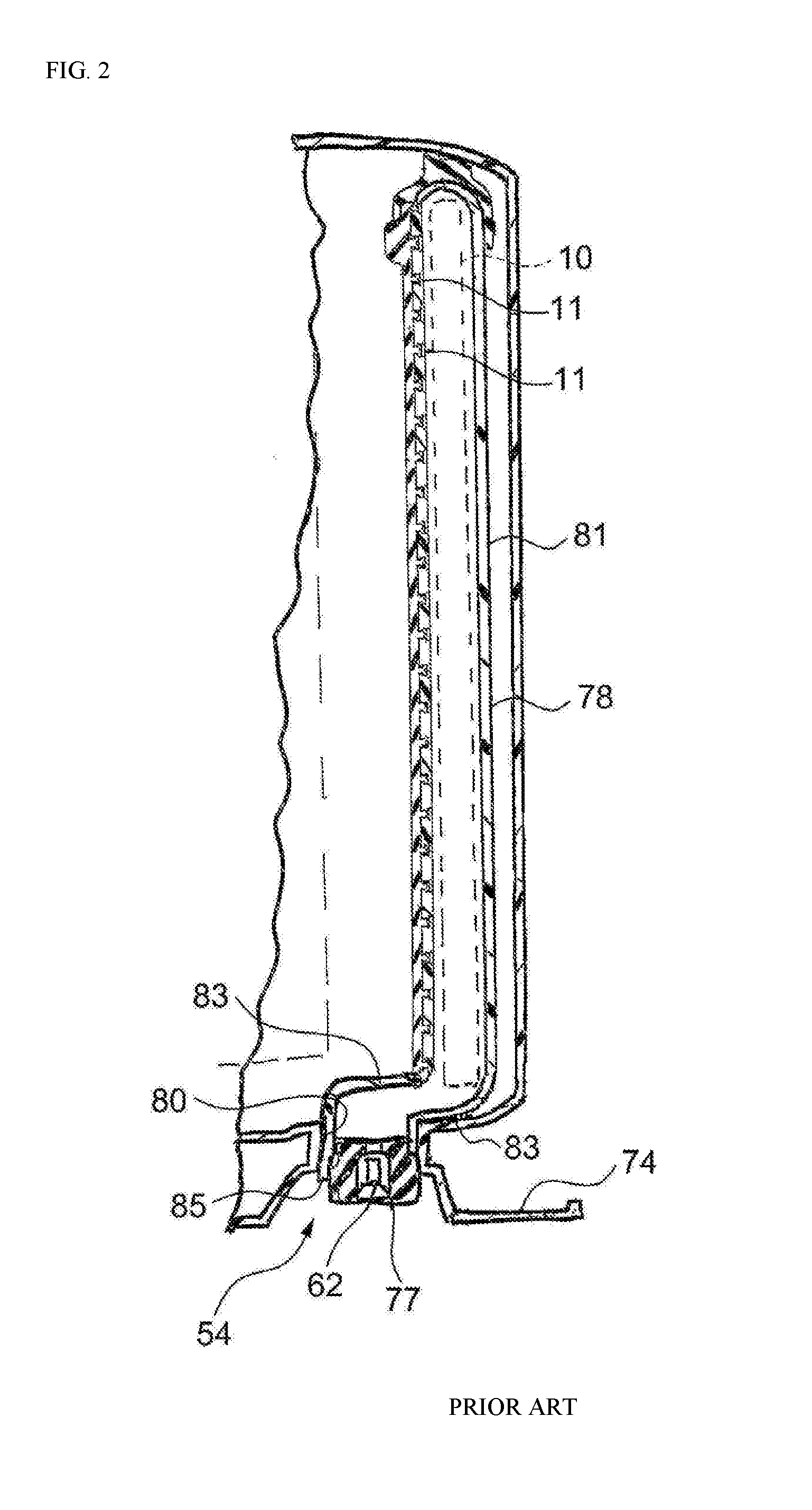

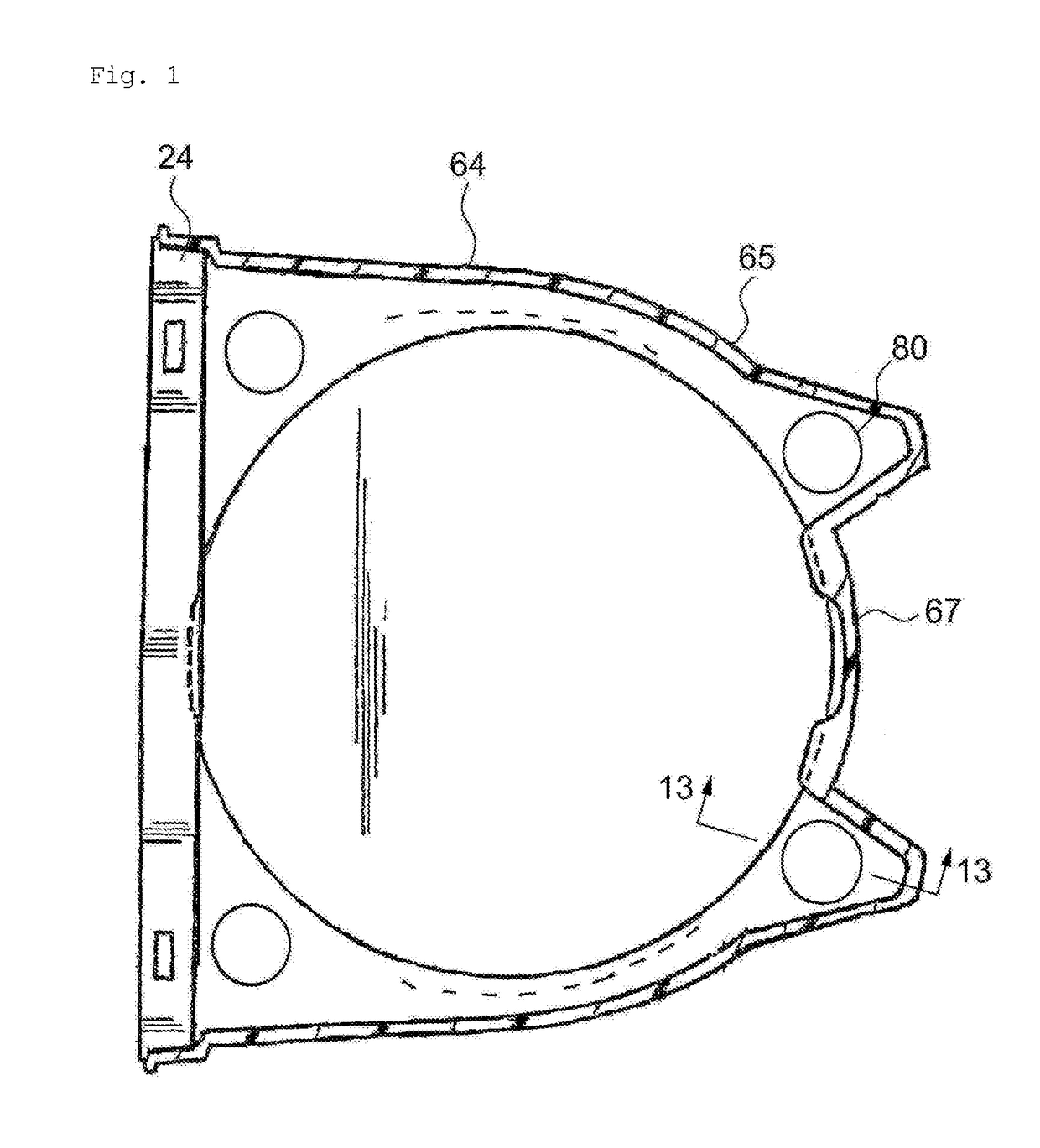

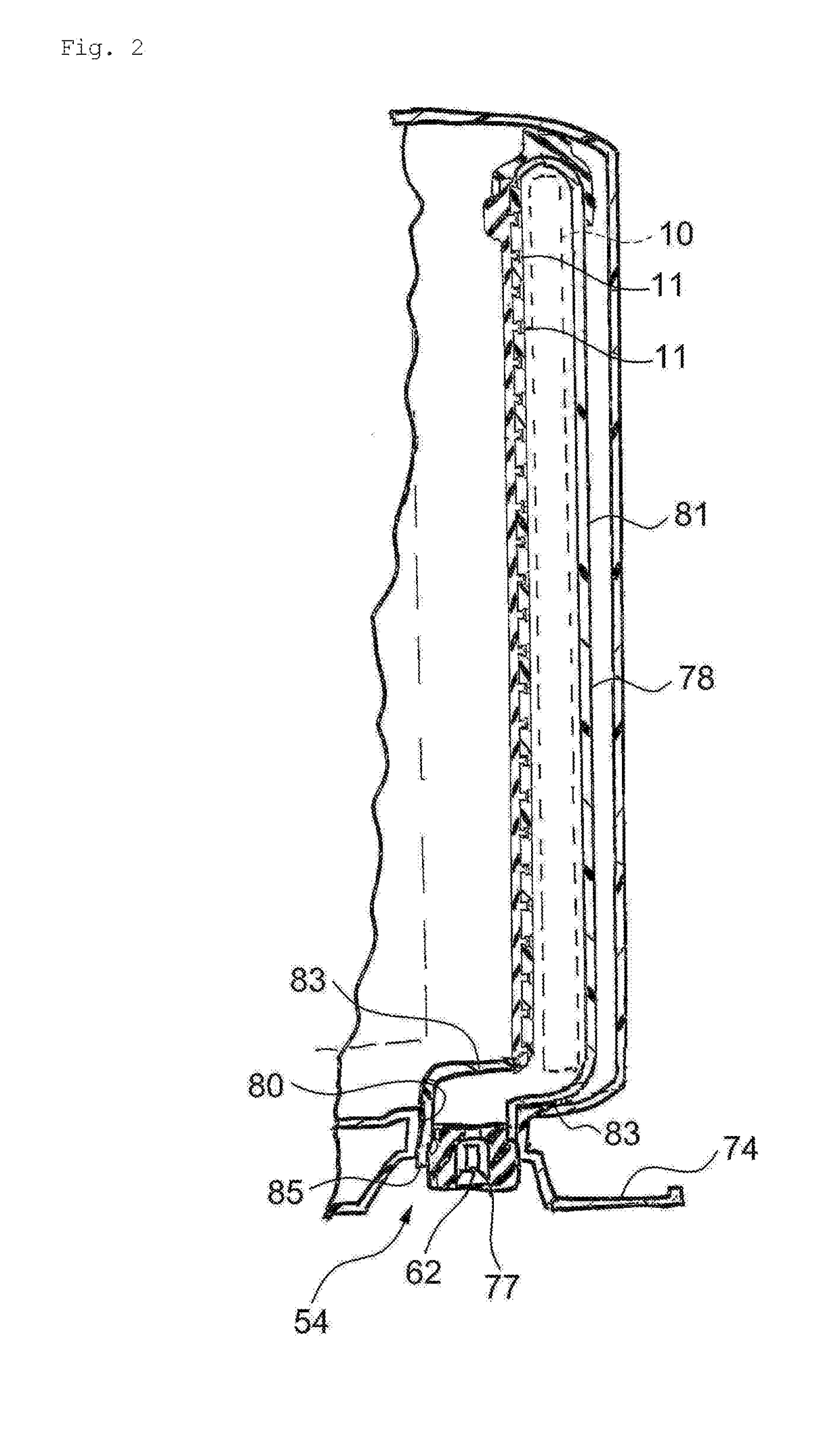

Rubber injection molding device and rubber product manufacturing method

InactiveUS20060061015A1Eliminate generationShorten vulcanization timePlastic recyclingFood shapingEngineeringPlunger

A rubber injection molding device comprising: a mold hang a molding cavity therein; an injecting machine including an injection cylinder having an injection chamber for storing a rubber therein, and an injection plunger for injecting the rubber from the injection chamber into the molding cavity by means of an advancement of the injection plunger; a feed machine having a feed cylinder with a feed aperture formed at a tip end thereof and connected with the injection chamber through a feed duct, and being adapted to feed into the injection chamber, through the feed duct the rubber in a mixed state, and a pushing assembly which pushes into the injection chamber the rubber that remains within the feed duct after a feed operation of the rubber by the feed machine. A manufacturing method of a rubber product by using the molding device is also disclosed.

Owner:SUMITOMO RIKO CO LTD +1

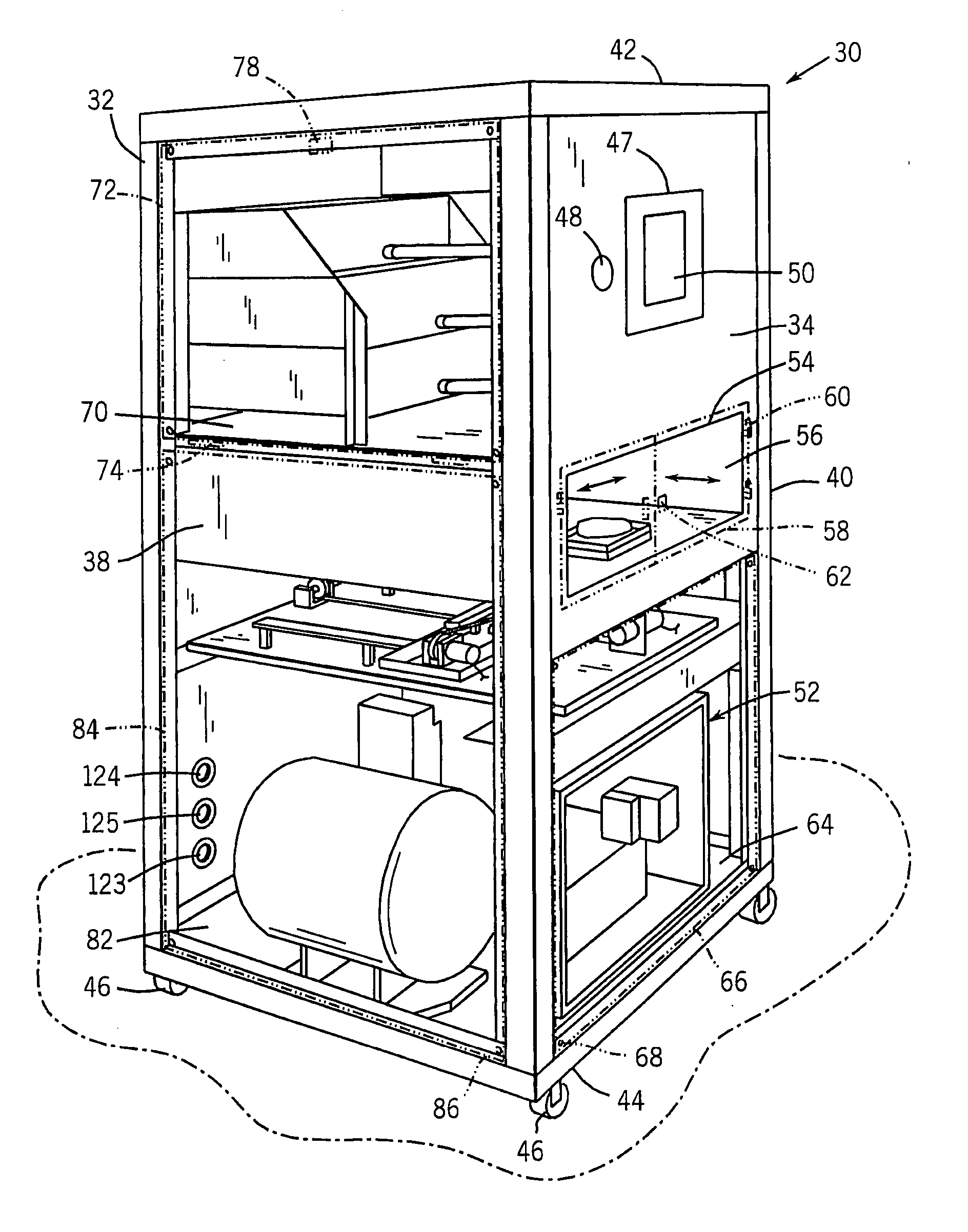

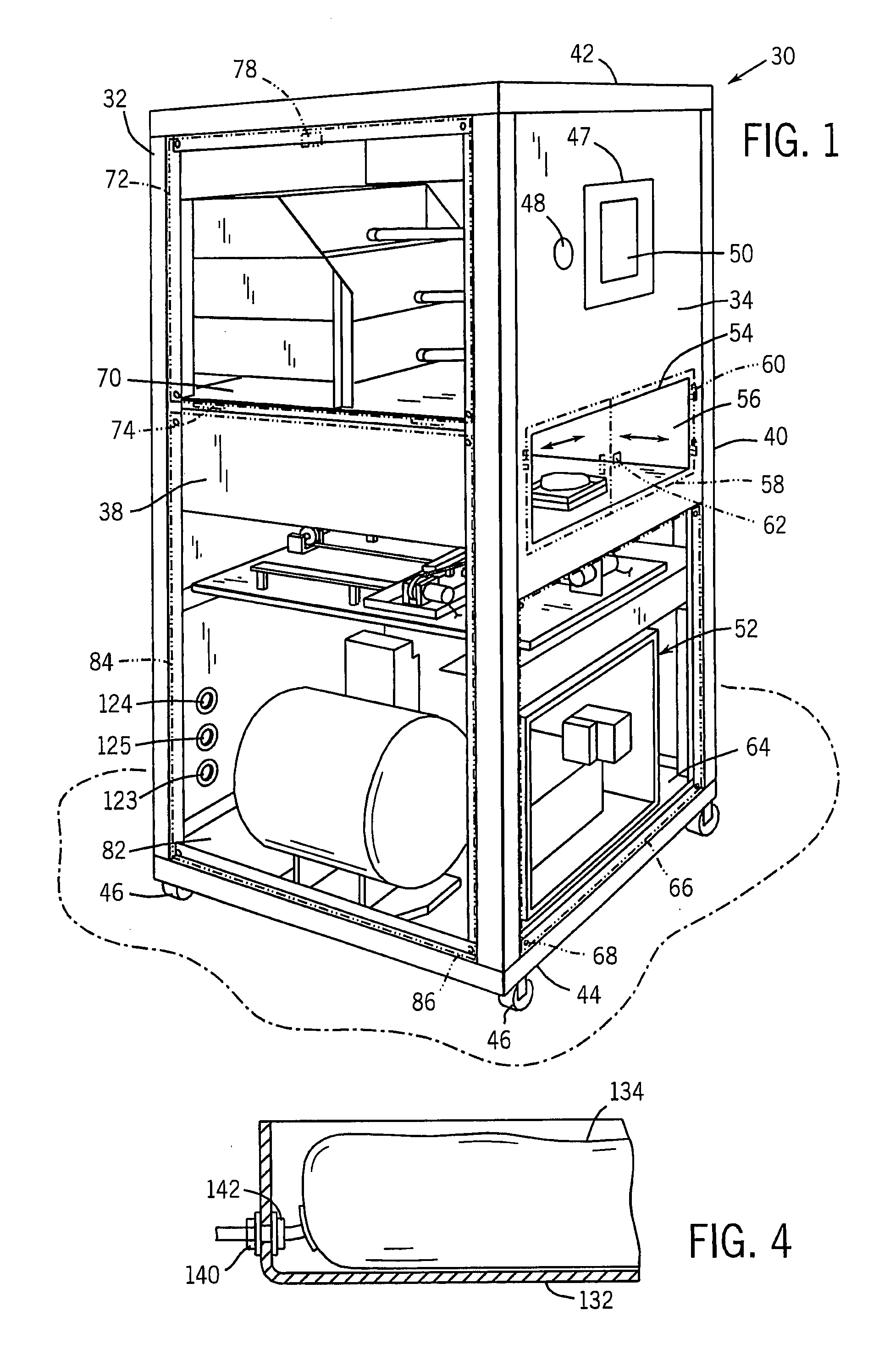

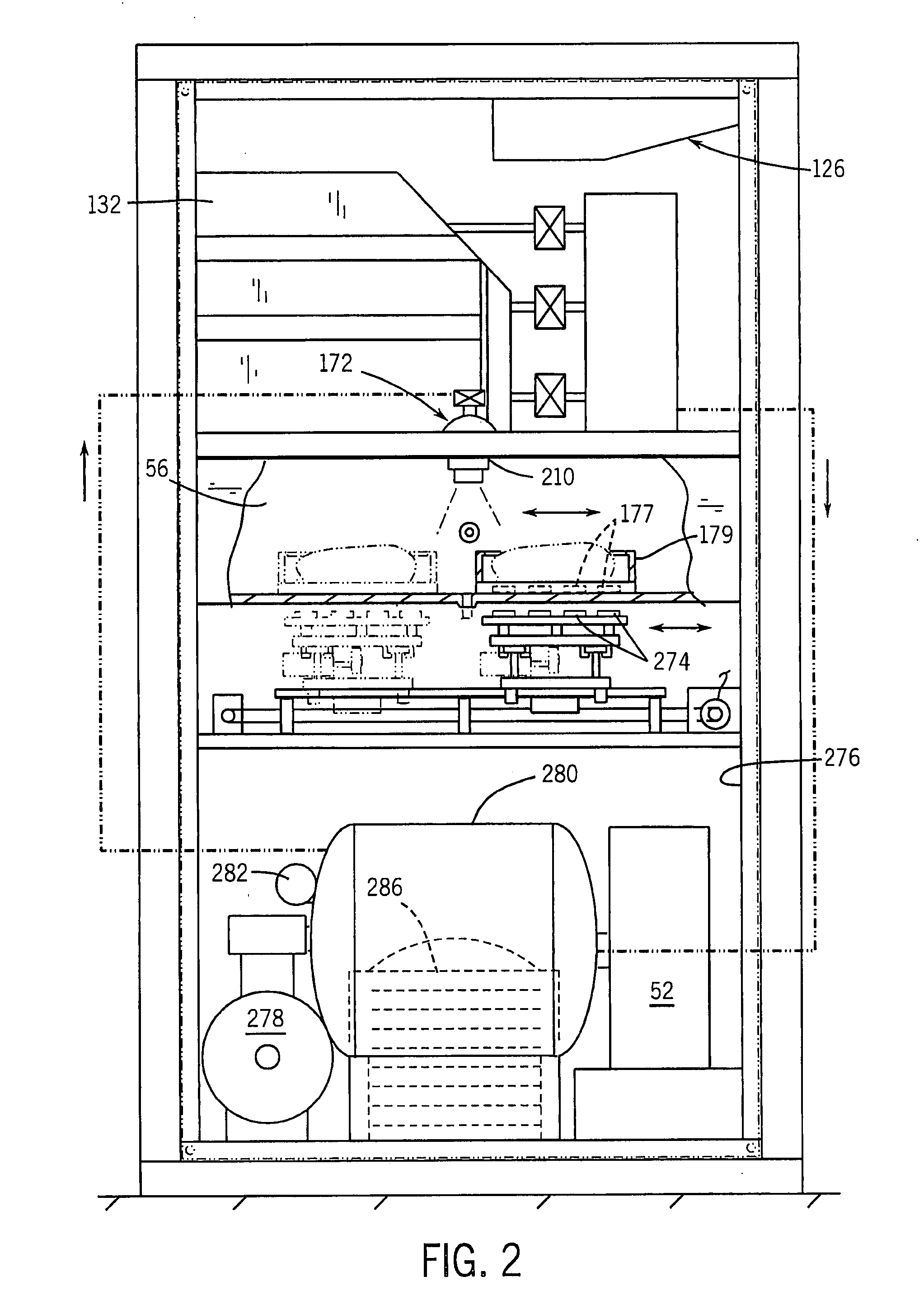

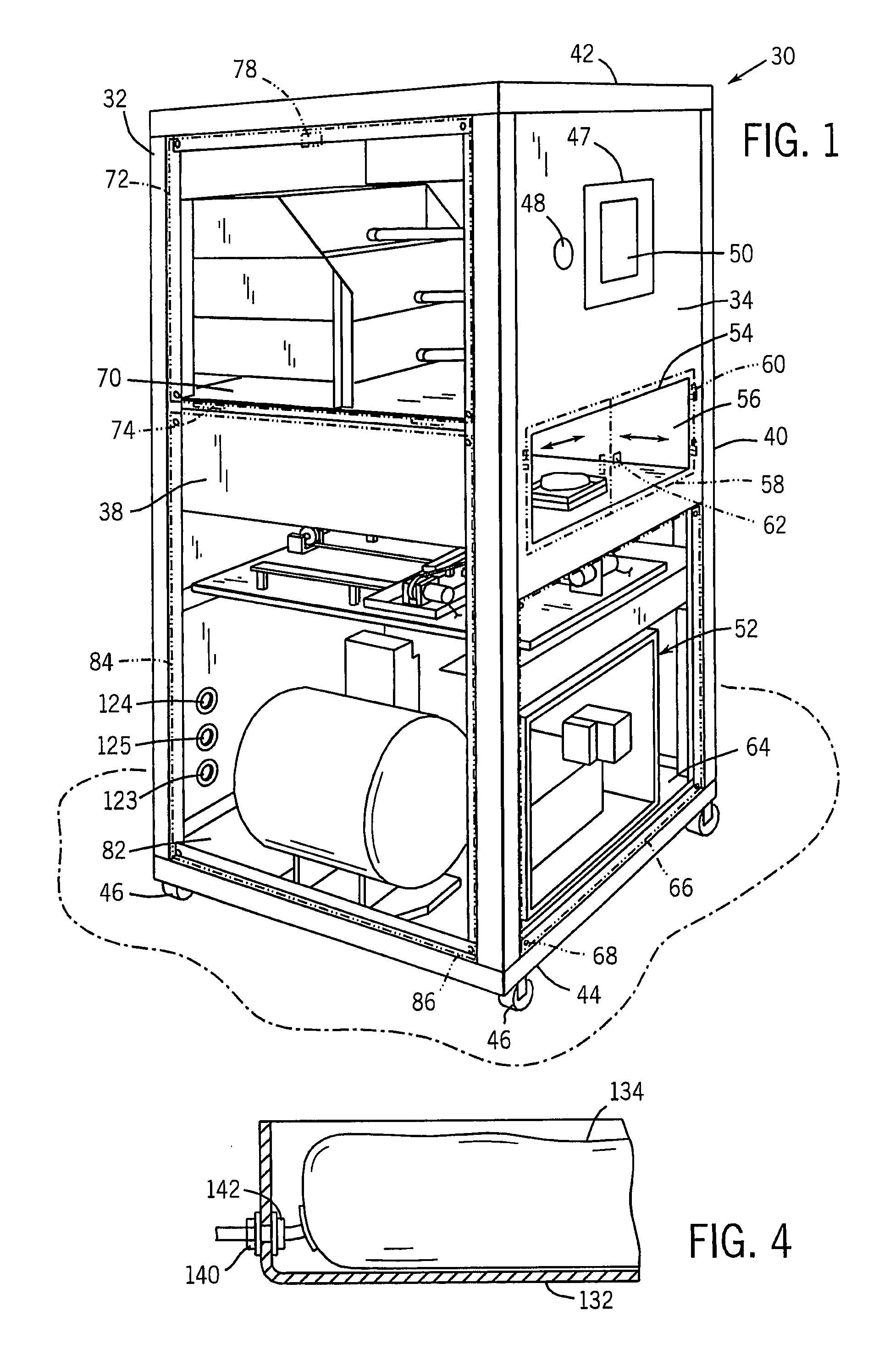

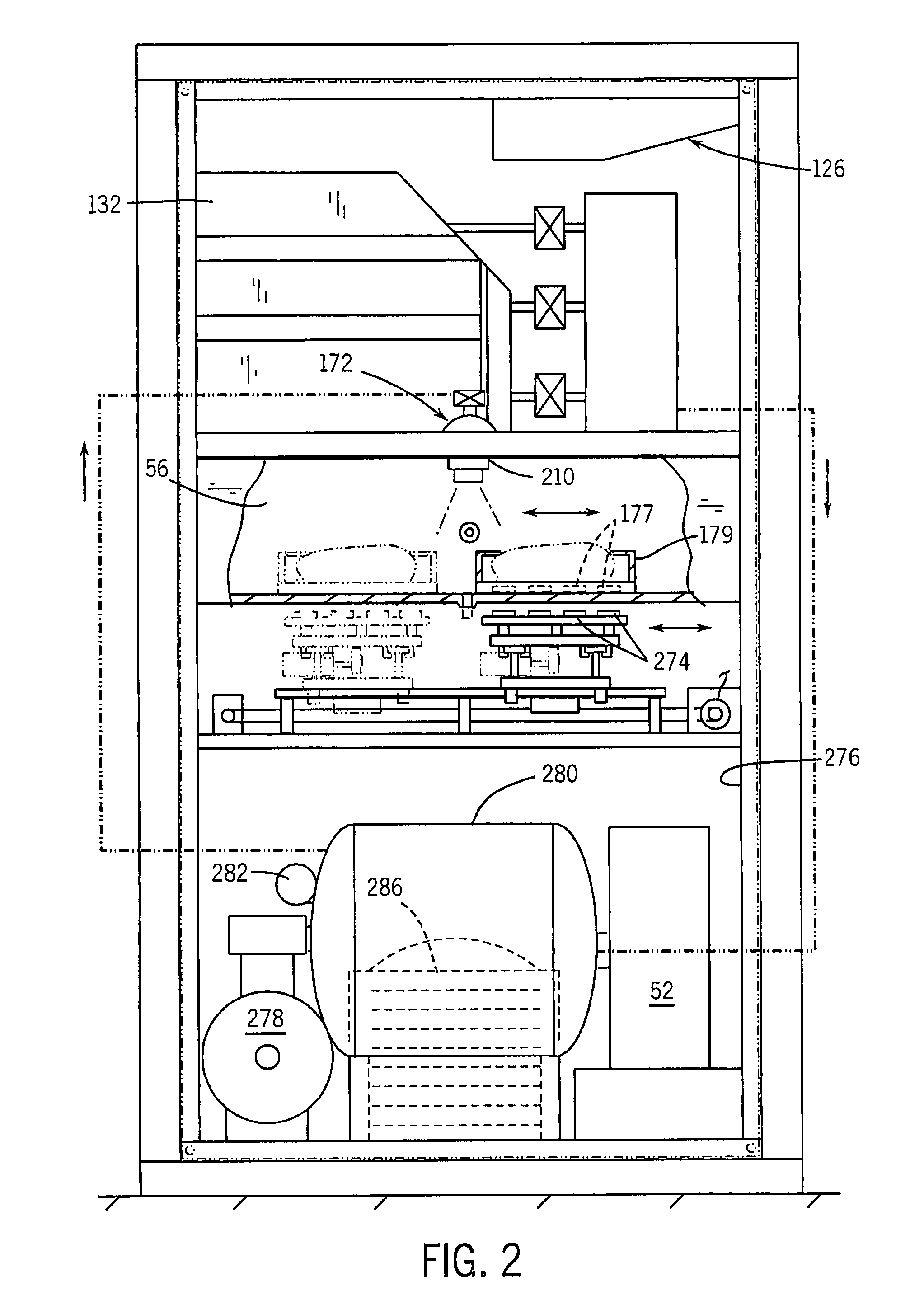

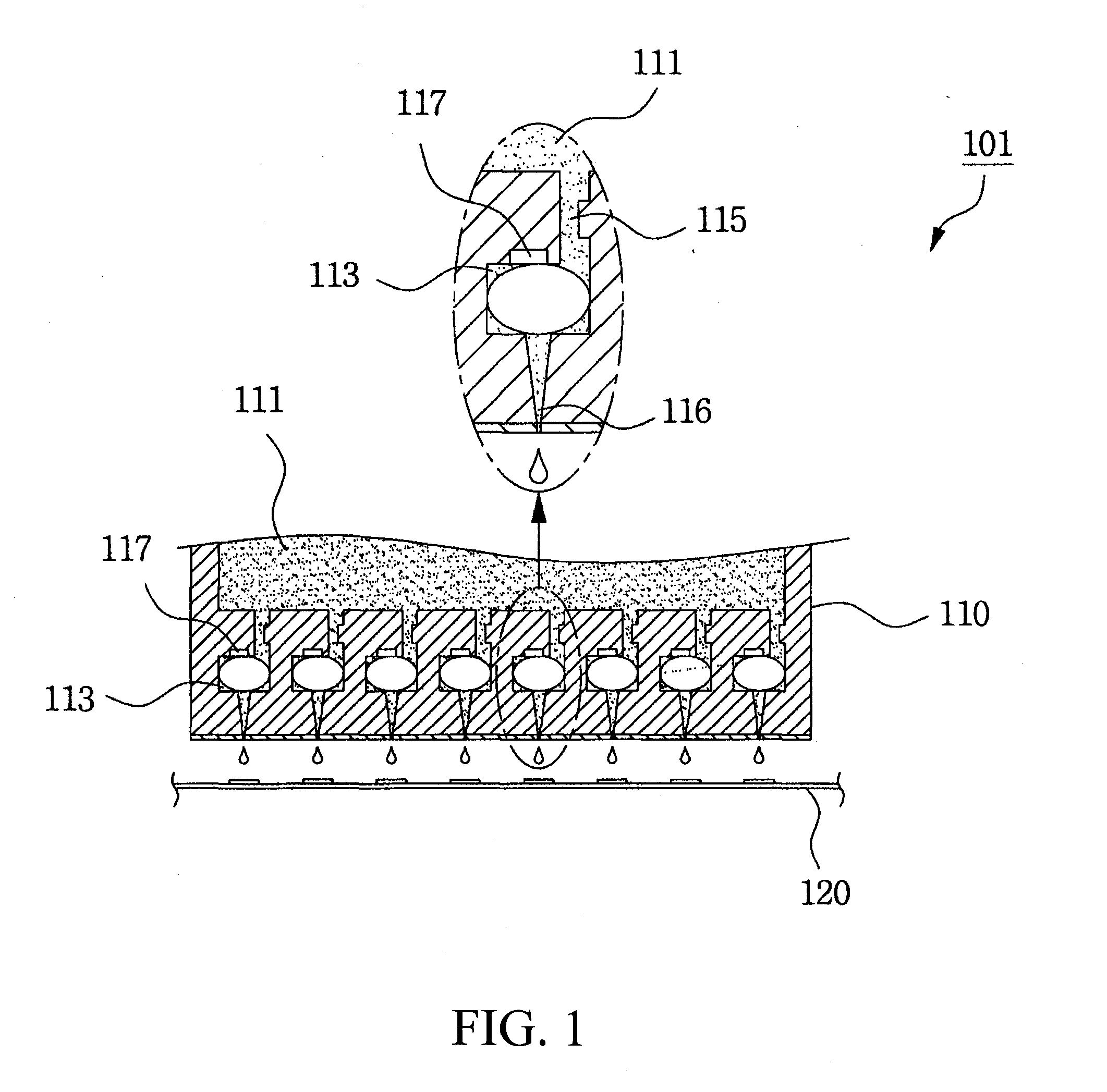

Needleless injection device and method of injecting

InactiveUS20080044526A1Enhance market appealBroad possible marketJet injection syringesInjection based meat processingFood additiveNeedle Free Injection

A needleless injection device and method for injecting a food subject is disclosed in which one or more types of liquid food additive are individually and / or simultaneously delivered to a food subject within a sealed injection chamber or compartment. The needleless injection device and method of the present invention utilizes rapid, high pressure injection bursts to completely and uniformly inject the food subject, allowing different food subjects or different food additives to be sequentially injected in an efficient and instant manner. The needleless injection device and method for injecting minimizes contamination by totally enclosing the injection process within a sealed chamber, and by eliminating the need for the injection nozzles to contact, or be placed immediately adjacent to the food subject.

Owner:HANSEN CONLY L +1

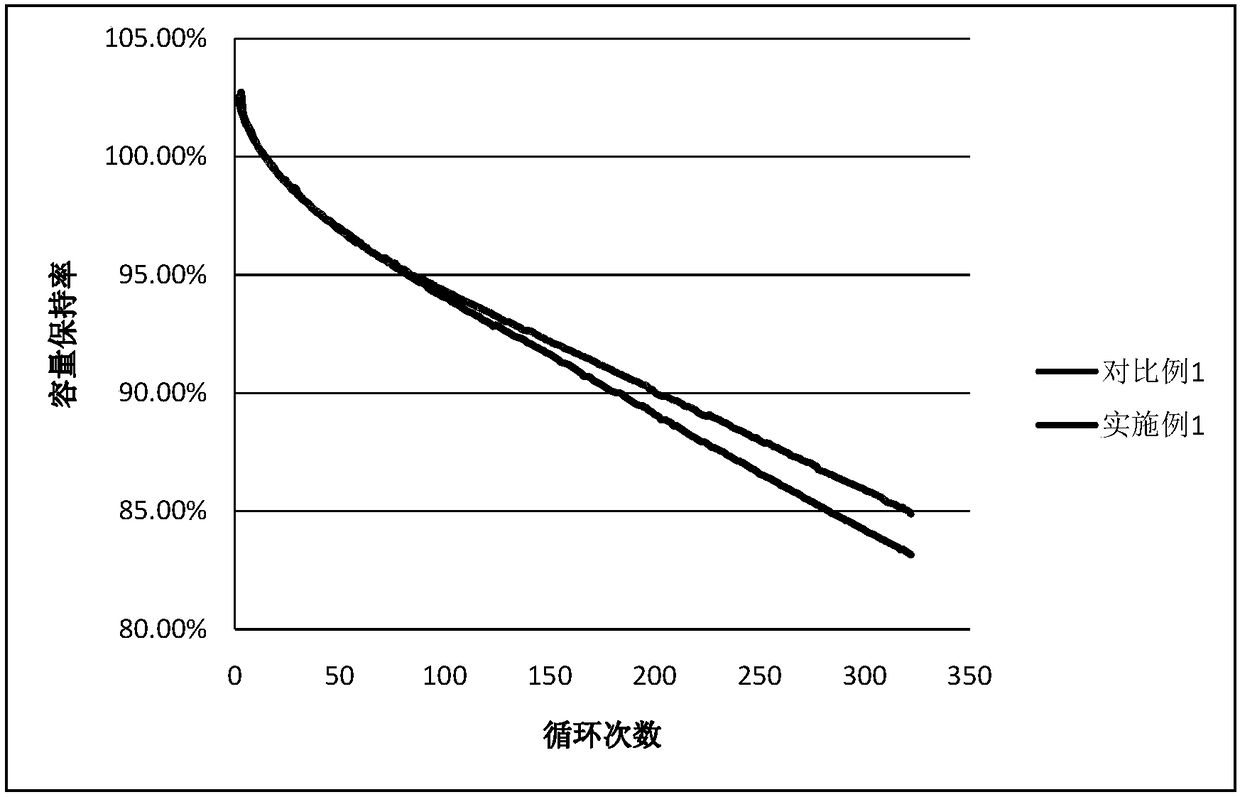

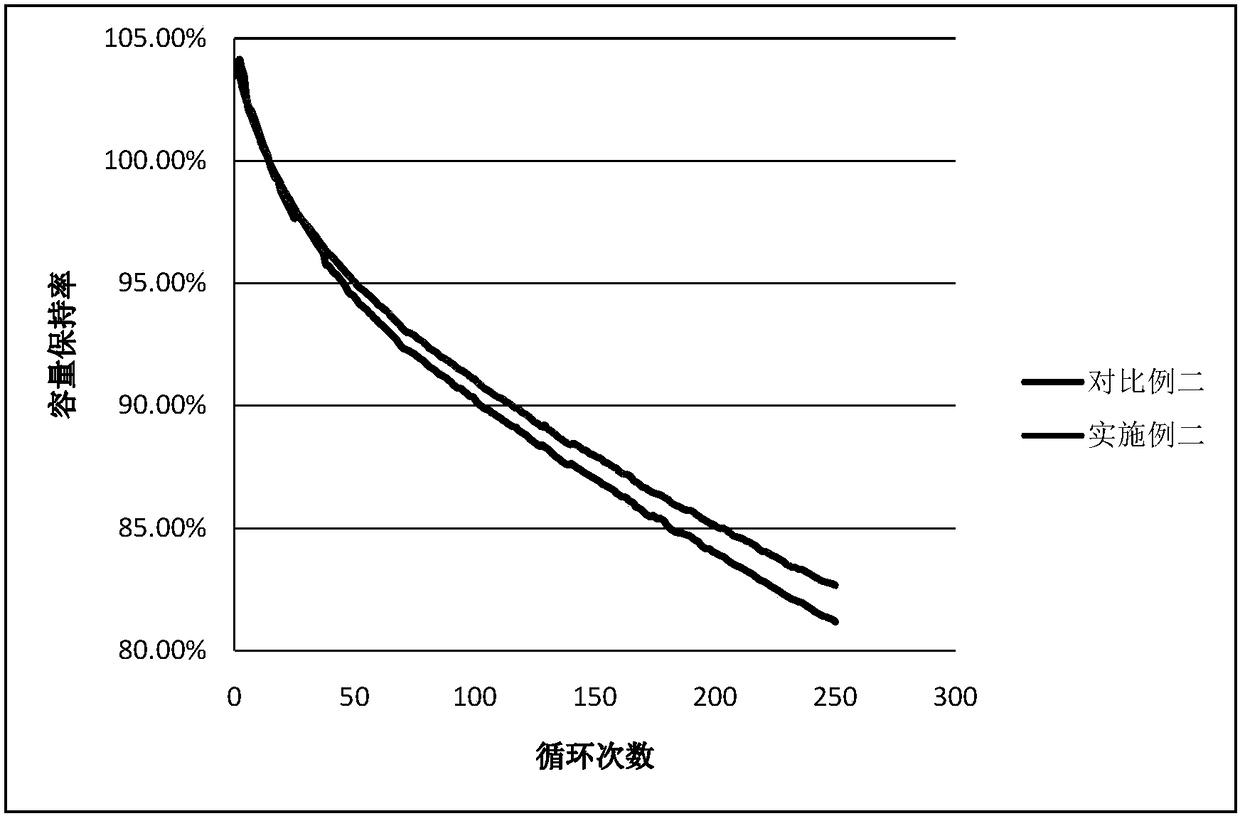

Method for formation and capacity grading of lithium ion battery with silicon-carbon cathode

ActiveCN108321436AAlleviate volume expansionBuffer volume expansionFinal product manufactureElectrolyte accumulators manufactureCyclic processEngineering

The invention discloses a method for formation and capacity grading of a lithium ion battery with a silicon-carbon cathode. The method comprises the following steps: feeding a battery cell which is not sealed after electrode injection and aging onto a cabinet, and performing formation so as to obtain a first battery cell; performing high-temperature aging treatment on the first battery cell so asto obtain a secondary battery cell; transferring the second battery cell into an electrolyte injection room, exhausting gases, replenishing electrode, and leaving to standard so as to obtain a third battery cell; feeding the third battery cell onto the cabinet, and performing capacity grading so as to obtain a fourth battery cell; vacuuming and exhausting air of the fourth battery cell, replenhsing electrode, sealing, and leaving to stand. By adopting the method for formation and capacity grading of the lithium ion battery with the silicon-carbon cathode, gases generated in the formation process can be effectively alleviated and eliminated, electrolyte loss in former steps of the circulation process can be avoided, swelling of the battery in the recharge and discharge process can be reduced, and the circulation properties of the battery can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

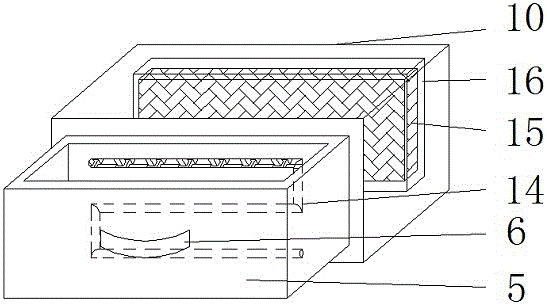

Sickbed special for hospital injection room

InactiveCN108969247AClean enoughReduce labor intensityLavatory sanitoryNursing bedsFixed frameDisinfectant

The invention relates to a medical sickbed, in particular to a sickbed special for a hospital injection room. The sickbed special for the hospital injection room aims at achieving the technical purposes that the two sides of a sickbed board can be used, the used side of the sickbed board can be disinfected and isolated, a patient can be prevented from being damaged by a disinfectant, and meanwhilethe labor intensity of medical staff is reduced. According to the technical scheme, the sickbed special for the hospital injection room comprises support legs, fixing frames, an N-shaped frame, a backrest plate, the double-sided bed board, an L-shaped support tube, a first rotating shaft, a rolling wheel, a sliding rail, a sliding block, a first motor and the like; the bottoms of the fixing frames are provided with the support legs, and a first through hole is formed in the middle of each fixing frame. According to the medical sickbed, the medical staff pull the double-sided bed board with the two hands to make the double-sided bed board rotate with the rolling wheel as a support point, and the purpose of turning over the double-sided bed board is achieved; the operation is simple, the labor intensity of the medical staff is reduced, and meanwhile a disinfection mechanism is utilized for disinfecting the double-sided bed board with the replaced side.

Owner:龙仲民

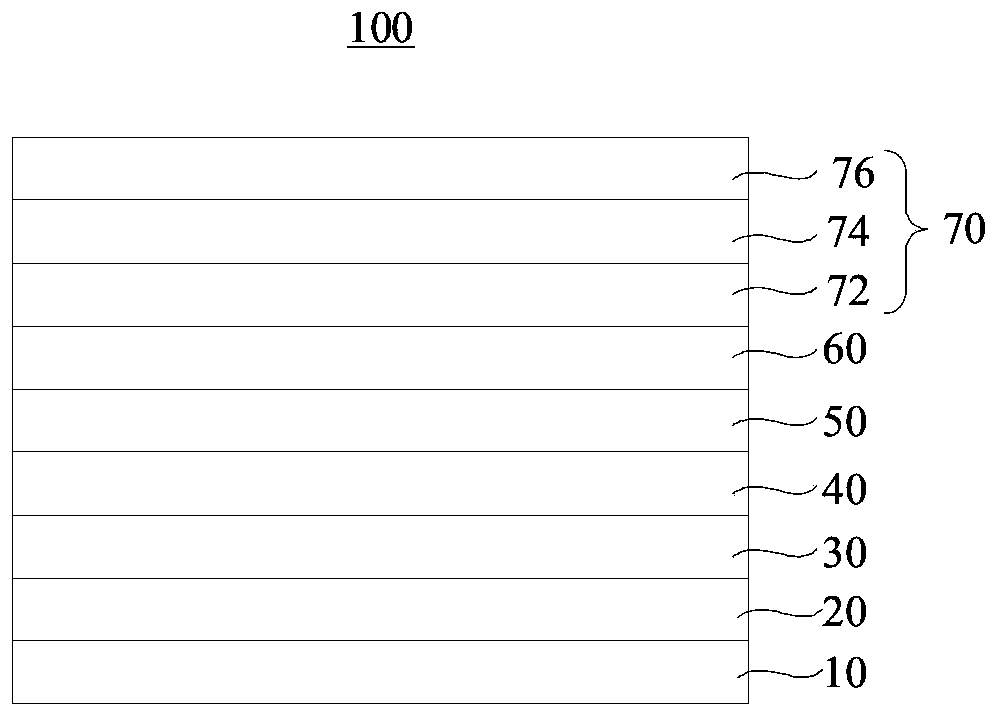

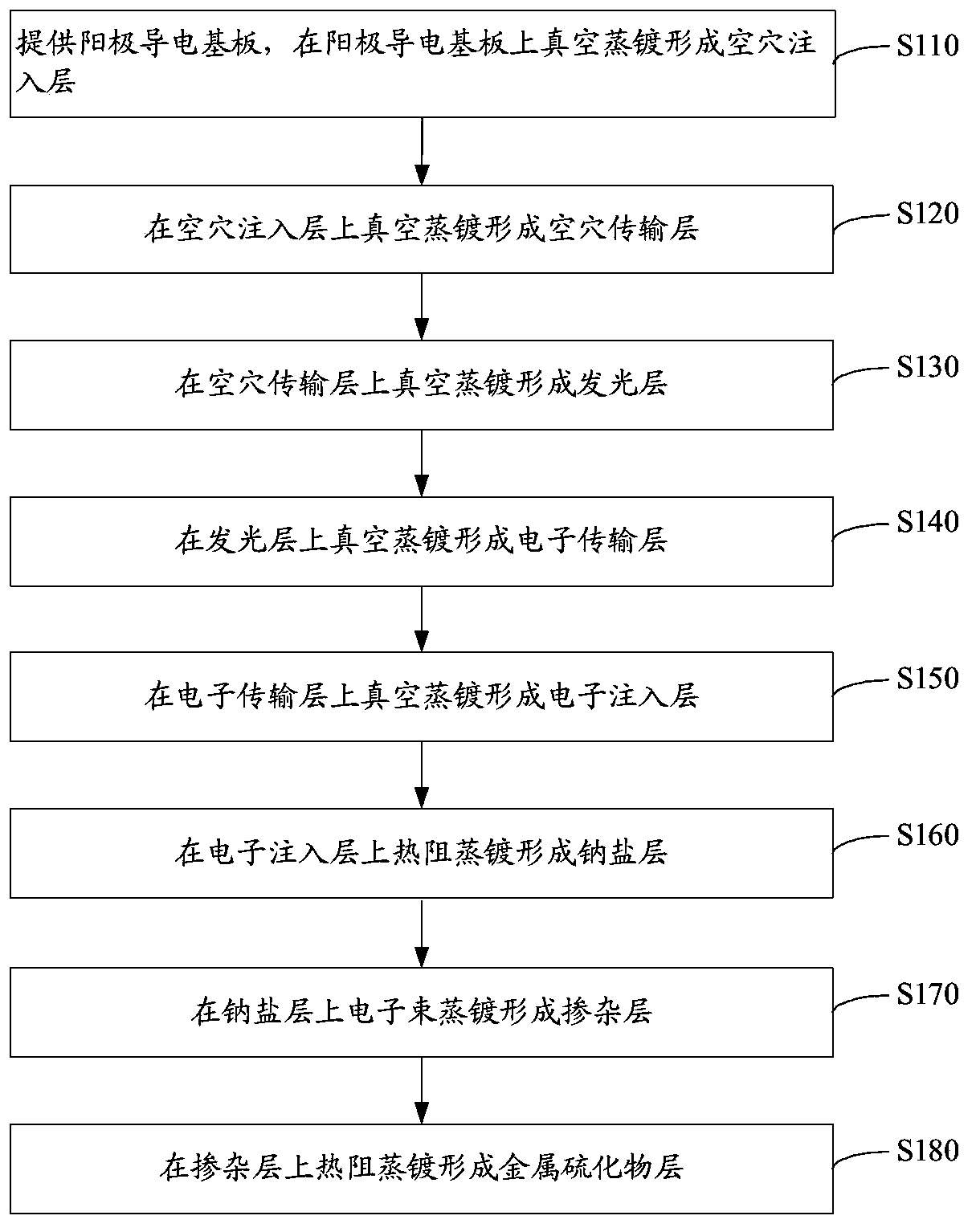

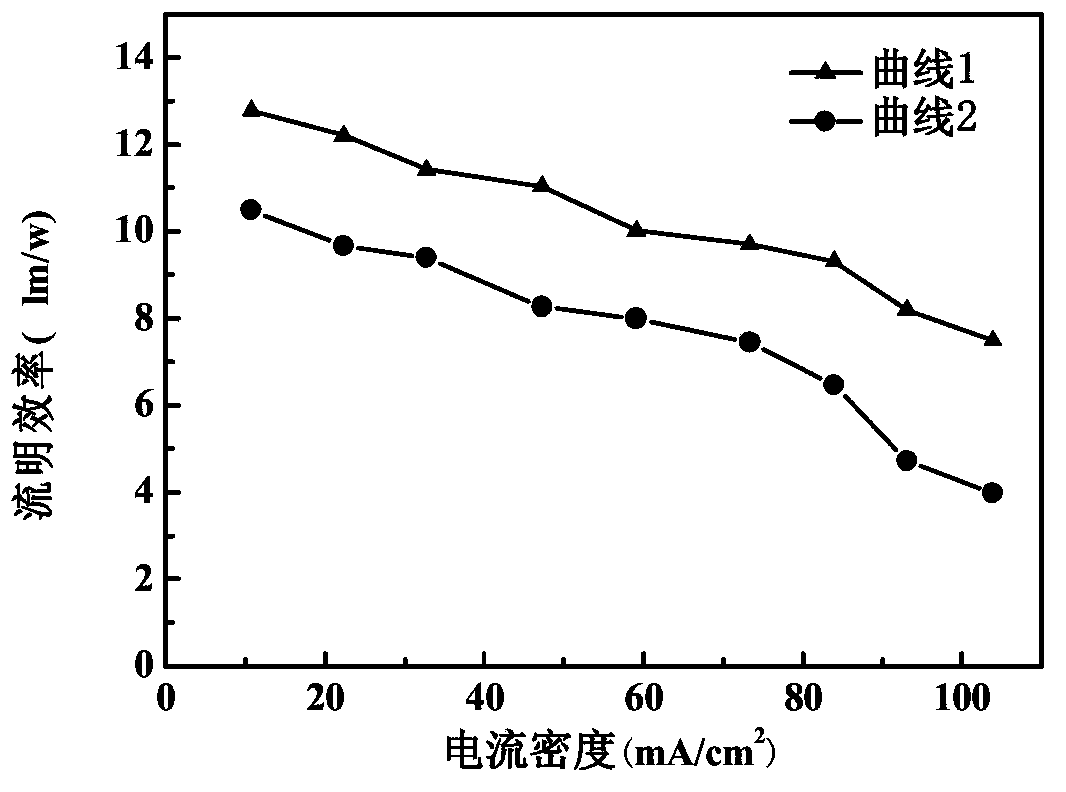

Organic electroluminescence device and preparation method thereof

InactiveCN104347811AImprove luminous efficiencyLower electron barrierSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionSilicon oxide

The invention relates to an organic electroluminescence device and a preparation method thereof. The organic electroluminescence device comprises an anode conductive substrate, a hole injection room, a hole transmission layer, a luminous layer, an electronic transmission layer, an electron injection layer and a cathode which are sequentially stacked, wherein the cathode comprises sodium salt layer, a doping layer and a metallic sulfide layer which are sequentially stacked on the electron injection layer; the material of the sodium salt layer is sodium carbonate, sodium fluoride, sodium chloride or sodium bromide; The material of the doping layer comprises rhenium oxide, a passivation material and metal; the rhenium oxide is rhenium heptoxide, rhenium dioxide, rhenium trioxide or rhenium sesquioxide; the passivation material is silicon oxide, aluminum oxide, nickelous oxide or copper oxide; the metal is magnesium, strontium calcium or ytterbium; the material of the metallic sulfide room is zinc sulfide, cadmium sulfide, magnesium sulfide or copper sulphide. The organic electroluminescence device is high in luminous efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

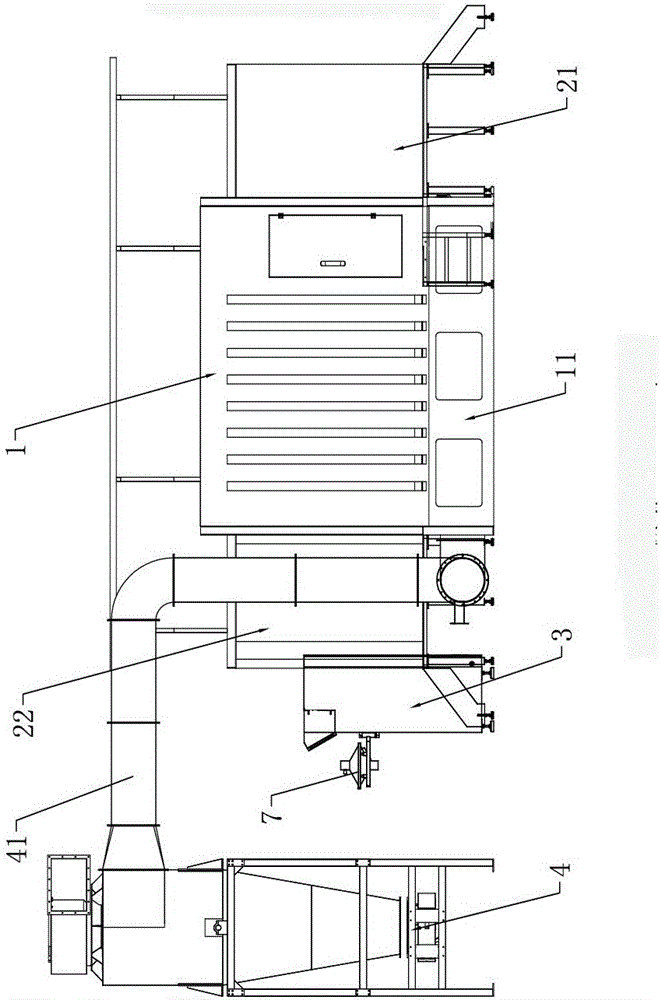

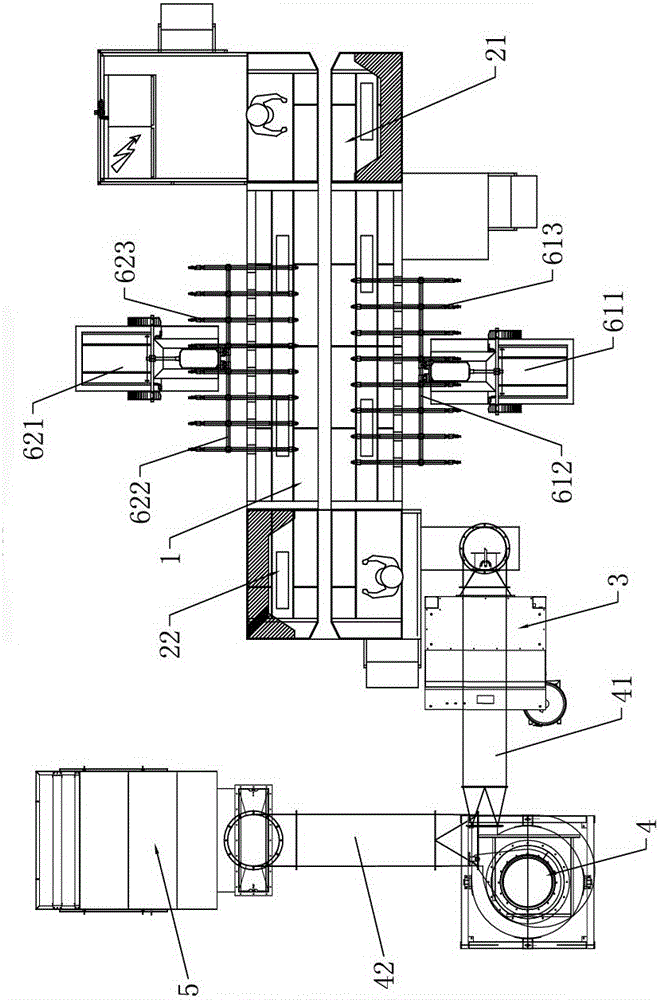

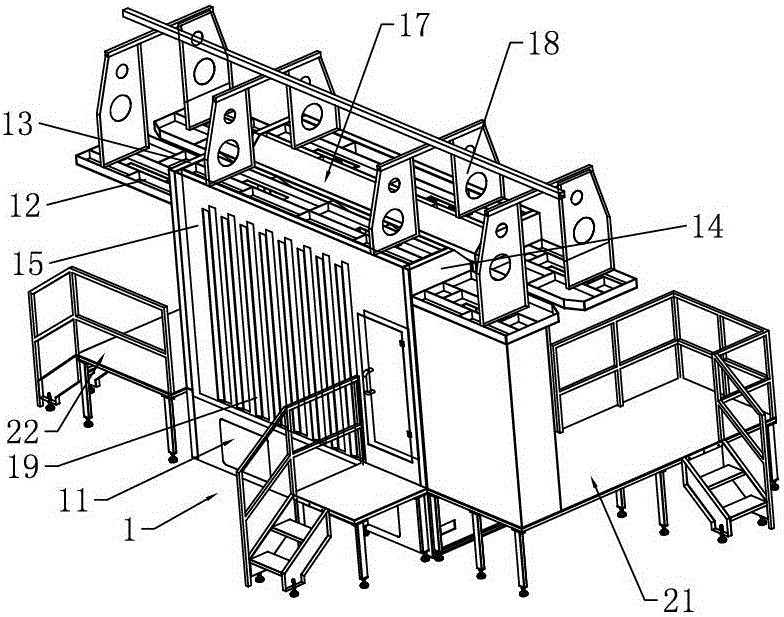

Aluminum profile automatic powder injection processing production line

PendingCN106824648AAutomatic and efficient powder spraying processAutomatic powder spraying processing is automatic and efficientLiquid spraying plantsLiquid supply arrangementsProduction lineFixed frame

The invention discloses an aluminum profile automatic powder injection processing production line which comprises a powder injection room, a feeding working platform, a discharge working platform, an automatic powder supply barrel, a cyclone separator, a rotary vane type filter, a front side automatic lifting machine and a back side automatic lifting machine; the powder injection room is composed of an injection room base, an injection room top plate, an injection room left side plate, an injection room right side plate, an injection room front side plate and an injection room back side plate; a material passing channel is formed in the powder injection room; a gantry frame is installed on the upper surface of the injection room top plate; the injection room base is composed of a base fixed frame and a U-shaped powder collection pipe; a movable overturning plate driven by an overturning plate drive mechanism is embedded in a powder collection chamber of the U-shaped powder collection pipe; and injection gun mounting frames are installed at the drive ends of the front side automatic lifting machine and the back side automatic lifting machine respectively and are provided with electrostatic injection guns supplied with powder by the automatic powder supply barrel respectively. The aluminum profile automatic powder injection processing production line can automatically and efficiently carry out powder injection processing on an aluminum profile, namely, the aluminum profile automatic powder injection processing production line has the advantages of novel structure design, high automation degree and high working efficiency.

Owner:佛山市澳斯腾尔科技有限公司

Single Actuator Fuel Injector for Duel Fuels

InactiveUS20160061168A1Internal combustion piston enginesFuel-injection pumpsCombustion chamberControl room

A fuel injector concurrently injects a liquid fuel and a gaseous fuel into a combustion chamber of an internal combustion engine. An interior wall of an injector body defines a control chamber and an injection chamber. A needle valve is disposed within the body and has a control surface fluidly communicating with the control chamber. A liquid fuel inlet fluidly communicates with the control chamber and a gaseous fuel inlet fluidly communicates with the injection chamber. A delivery passage is defined by at least one of the needle valve and the interior wall and configured to place the control chamber in fluid communication with the injection chamber to permit flow of liquid fuel therebetween.

Owner:CATERPILLAR INC

Cold wall furnace for preparation of graphene through CVD method and continuous production method

Owner:WUXI GRAPHENE FILM +1

Needleless injection device and method of injecting

InactiveUS7968135B2Quickly and easily flavoringEasy to useJet injection syringesInjection based meat processingNeedle Free InjectionFood additive

A needleless injection device and method for injecting a food subject is disclosed in which one or more types of liquid food additive are individually and / or simultaneously delivered to a food subject within a sealed injection chamber or compartment. The needleless injection device and method of the present invention utilizes rapid, high pressure injection bursts to completely and uniformly inject the food subject, allowing different food subjects or different food additives to be sequentially injected in an efficient and instant manner. The needleless injection device and method for injecting minimizes contamination by totally enclosing the injection process within a sealed chamber, and by eliminating the need for the injection nozzles to contact, or be placed immediately adjacent to the food subject.

Owner:HANSEN CONLY L +1

Copper alloy explosion-proof instrument surface spraying technique

InactiveCN101096026AImprove explosion-proof performanceImprove completenessPretreated surfacesCoatingsEpoxyHybrid type

The invention relates to a spraying process for explosion-proof tool surface. At first, explosion-proof tool is sent to polishing workshop for careful pollution removal; then the product is sent to the surface treatment workshop and is hung in dry powder injection room. The distance between products is less than 75mm. The horizontal height maintains in 900mm. red epoxy dion mixed powder coating is sprayed on product surfaces by electrostatic generator. The thickness of added film is 6-8mm and electrostatic value is controlled in 40-60Kv. After resting for 2-3min the product is shifted to receiving frame by free railway and is sent to drying furnace slowly in sliding with uniform speed. After temperature is increased to 180deg.C the temperature is maintained for 25-30min. After it the product is sent to the polishing workshop again and working contact face of product is polished. The invention is provided with improved explosion-proof performance of tool, beautiful appearance, near zero oxidation degree, improved surface hardness and adhesive force.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

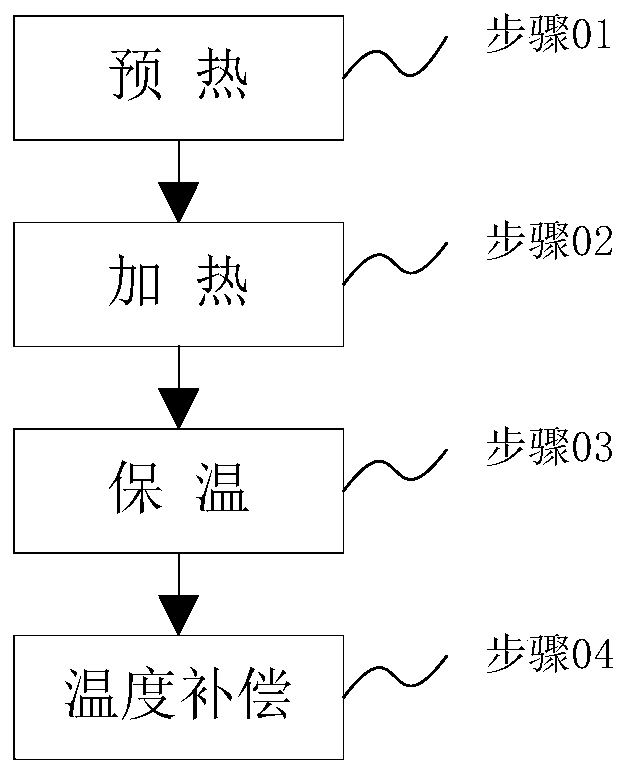

Electrolyte heating method and device

PendingCN110131884AEfficient use ofAvoid it happening againFinal product manufacturePrimary cellsElectrolysisRoom temperature

The invention relates to an electrolyte heating method and device, and belongs to the technical field of chemical engineering. The method comprises the following steps of preheating, heating, heat preserving, and temperature compensation. The electrolyte heating device comprises an electrolyte conveying pipe and multiple heaters. The liquid conveying pipe is used for conveying an electrolyte to anelectrolyte to an electrolyte injection room from an electrolyte storage room, the heaters are used for heating the multiple portions of the electrolyte conveying pipe, the portions comprise the electrolyte conveying pipe at the connecting position of the electrolyte storage room and the electrolyte injection room, a front half segment electrolyte conveying pipe of the electrolyte injection room,a rear half segment electrolyte conveying pipe of the electrolyte injection room and an electrolyte conveying pipe on an electrolyte injection machine electrolyte outlet. Through segmented heating and heat preservation, heat energy is effectively used, electrolyte temperature stability is maintained, a preheating device is started for stabilizing the electrolyte and room temperature difference, and the phenomenon that due to the large temperature difference, fluid resistance or bubbles are generated is avoided.

Owner:上海汇平新能源有限公司

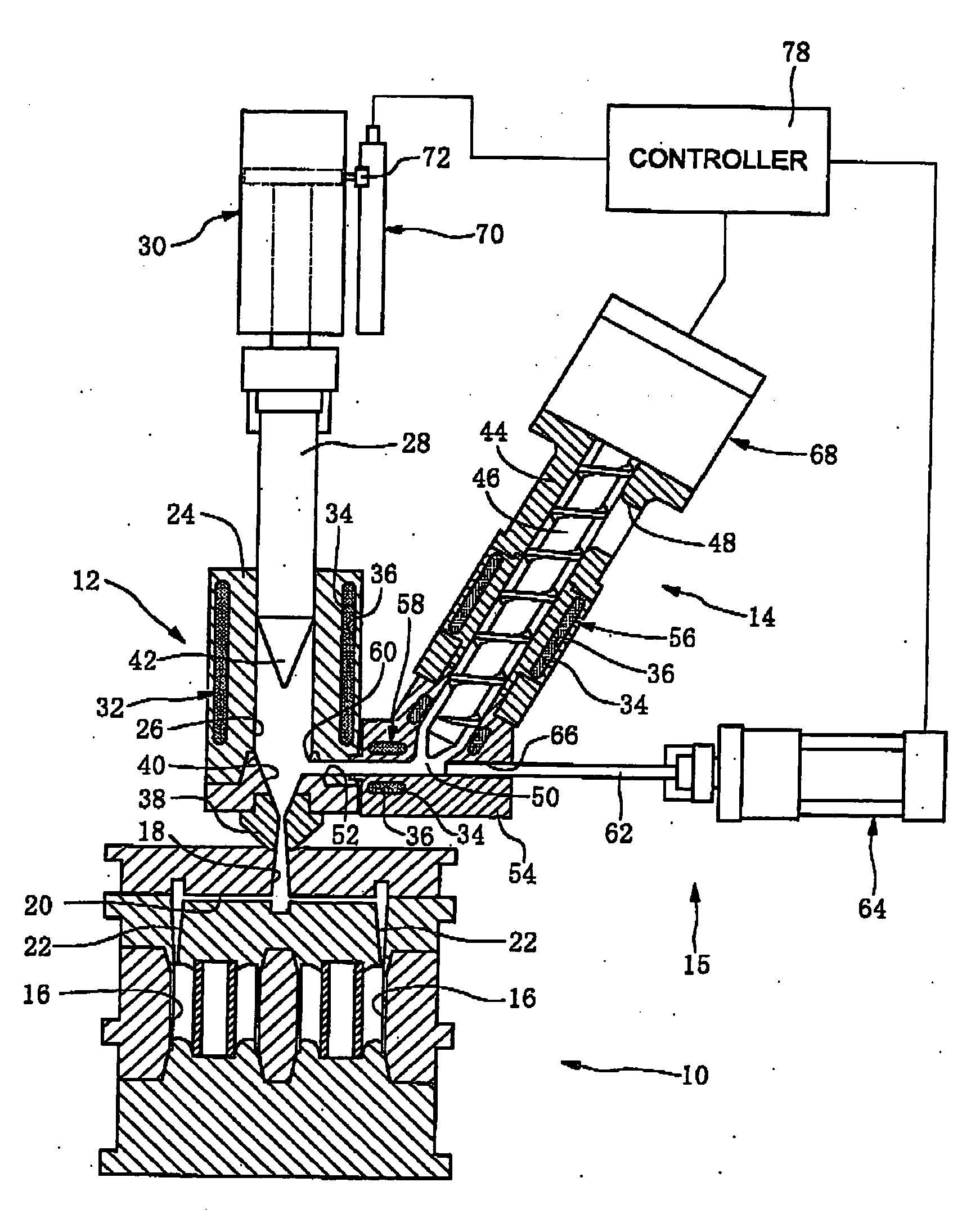

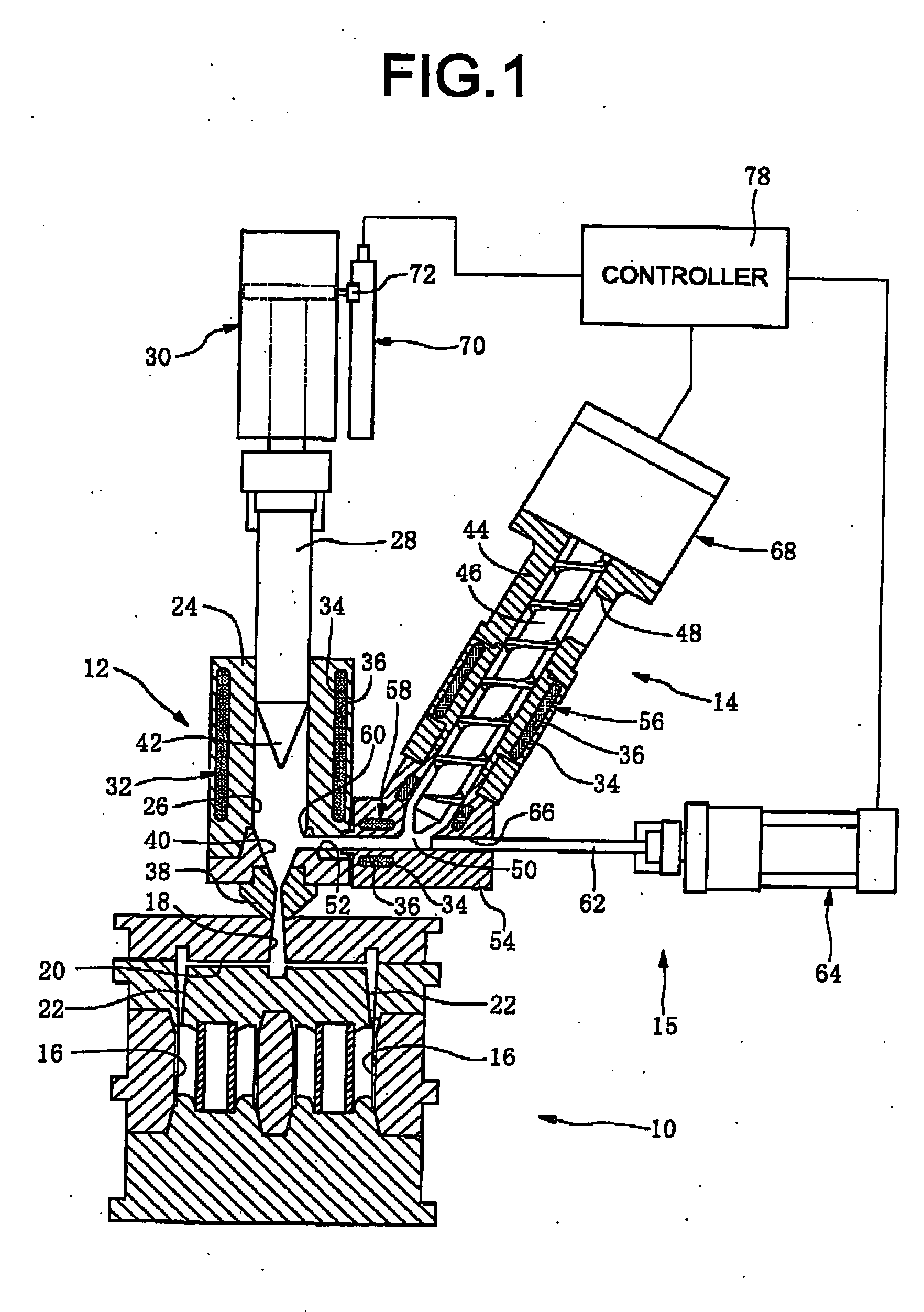

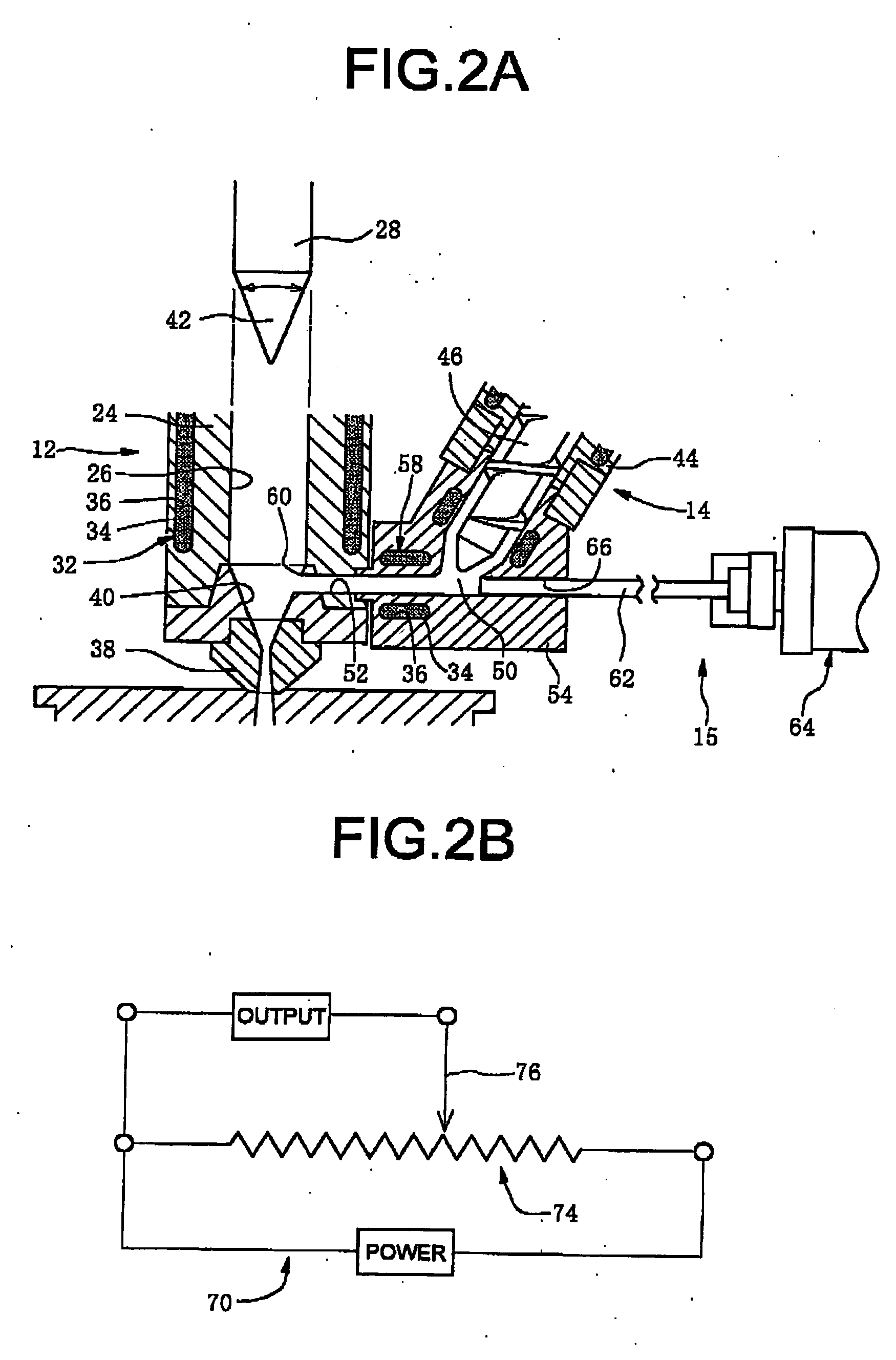

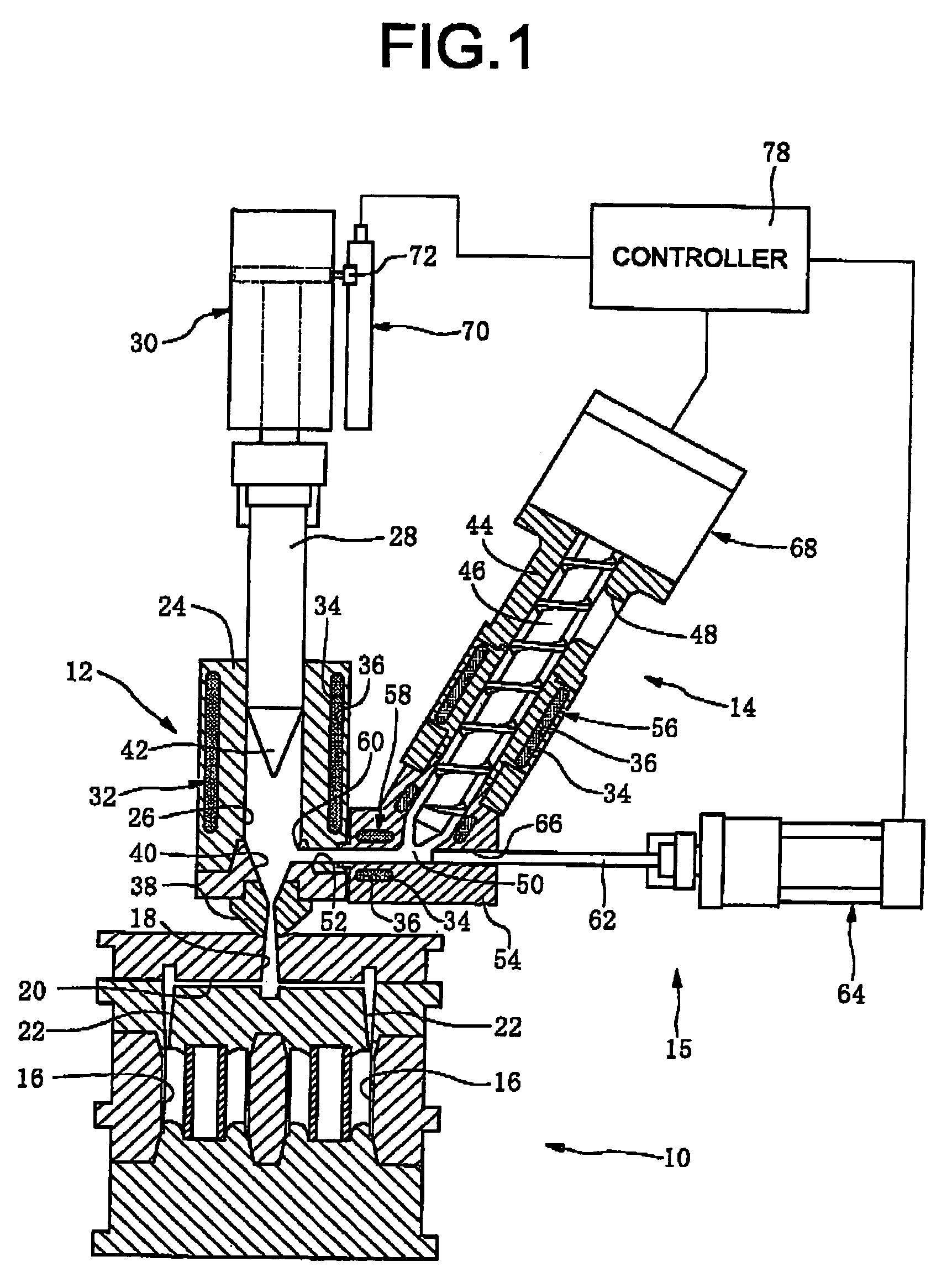

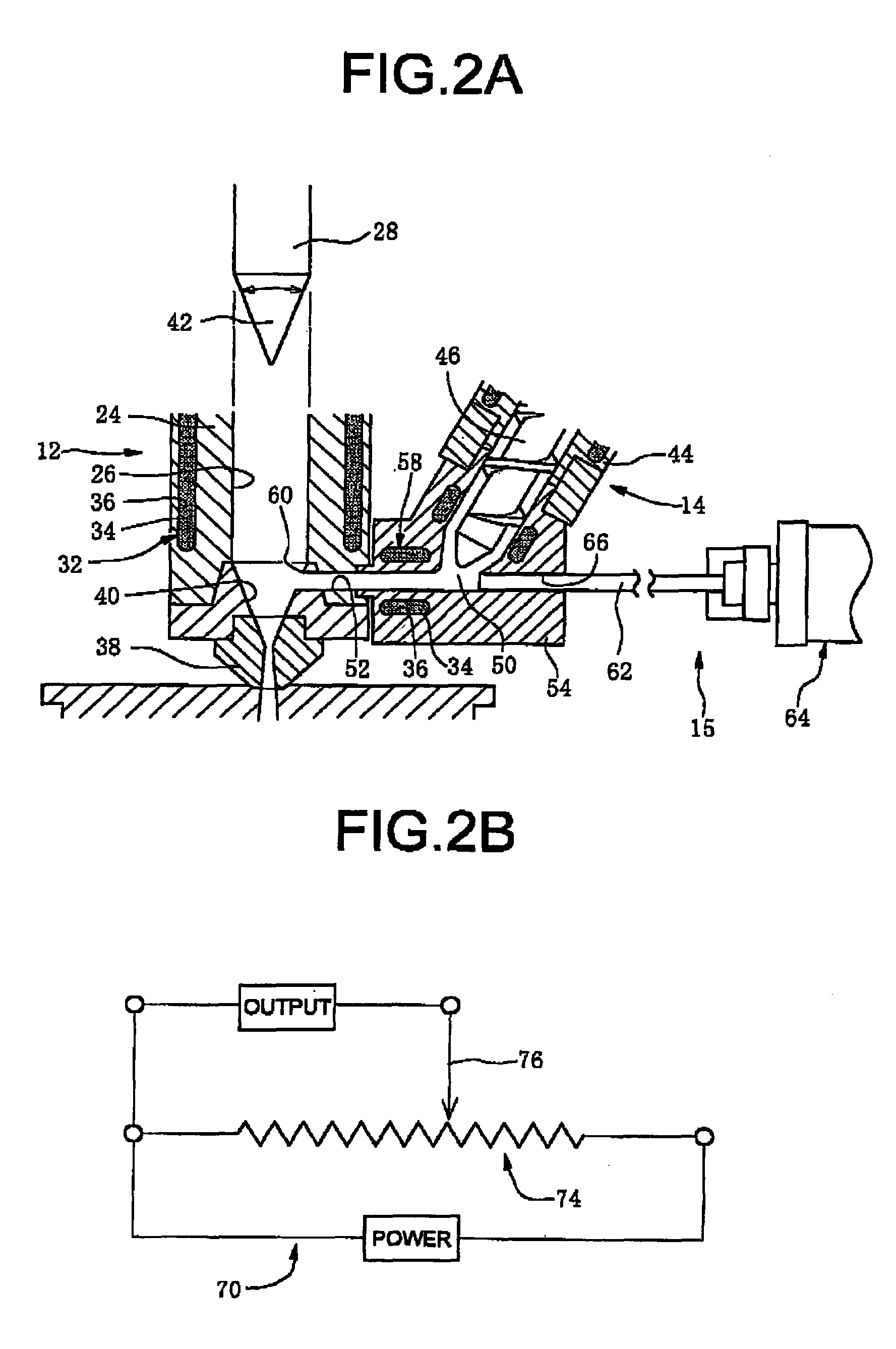

Rubber injection molding device and rubber product manufacturing method

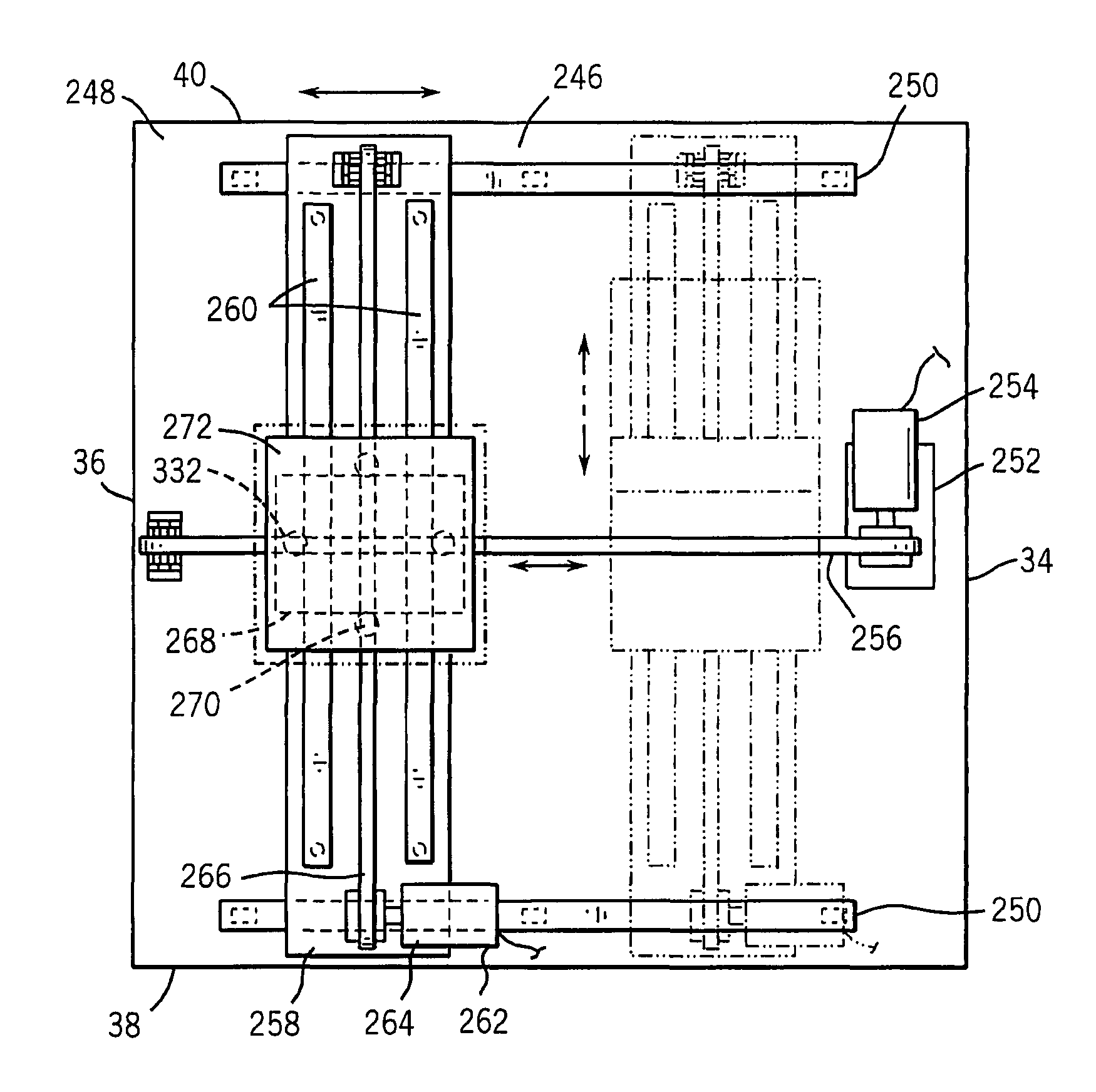

InactiveUS7615181B2Increase temperatureShorten vulcanization timePlastic recyclingFood shapingEngineeringInjection rooms

A rubber injection molding device comprising: a mold having a molding cavity therein; an injecting machine including an injection cylinder having an injection chamber for storing a rubber therein, and an injection plunger for injecting the rubber from the injection chamber into the molding cavity by means of an advancement of the injection plunger; a feed machine having a feed cylinder with a feed aperture formed at a tip end thereof and connected with the injection chamber through a feed duct, and being adapted to feed into the injection chamber, through the feed duct the rubber in a mixed state, and a pushing assembly which pushes into the injection chamber the rubber that remains within the feed duct after a feed operation of the rubber by the feed machine. A manufacturing method of a rubber product by using the molding device is also disclosed.

Owner:SUMITOMO RIKO CO LTD +1

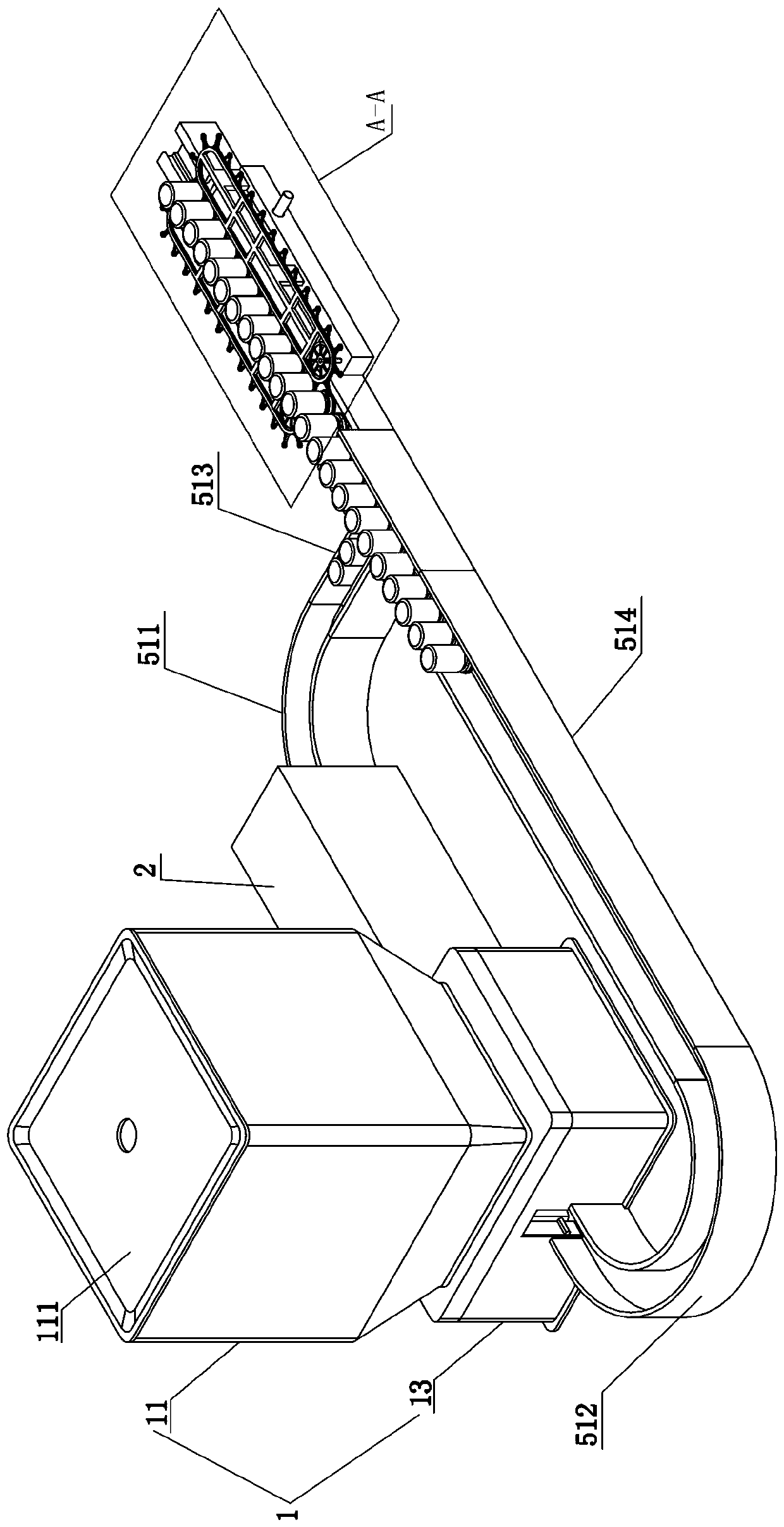

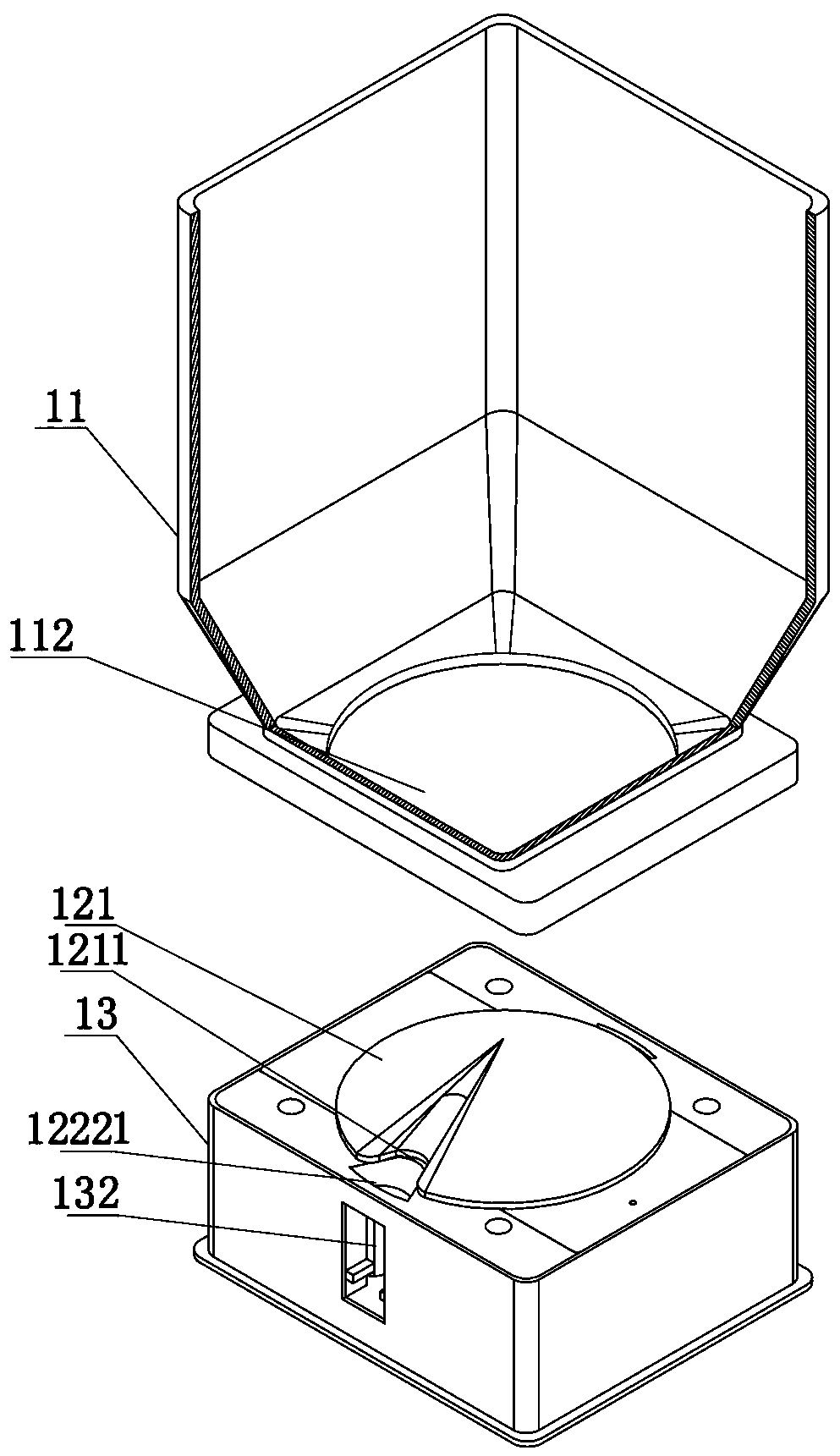

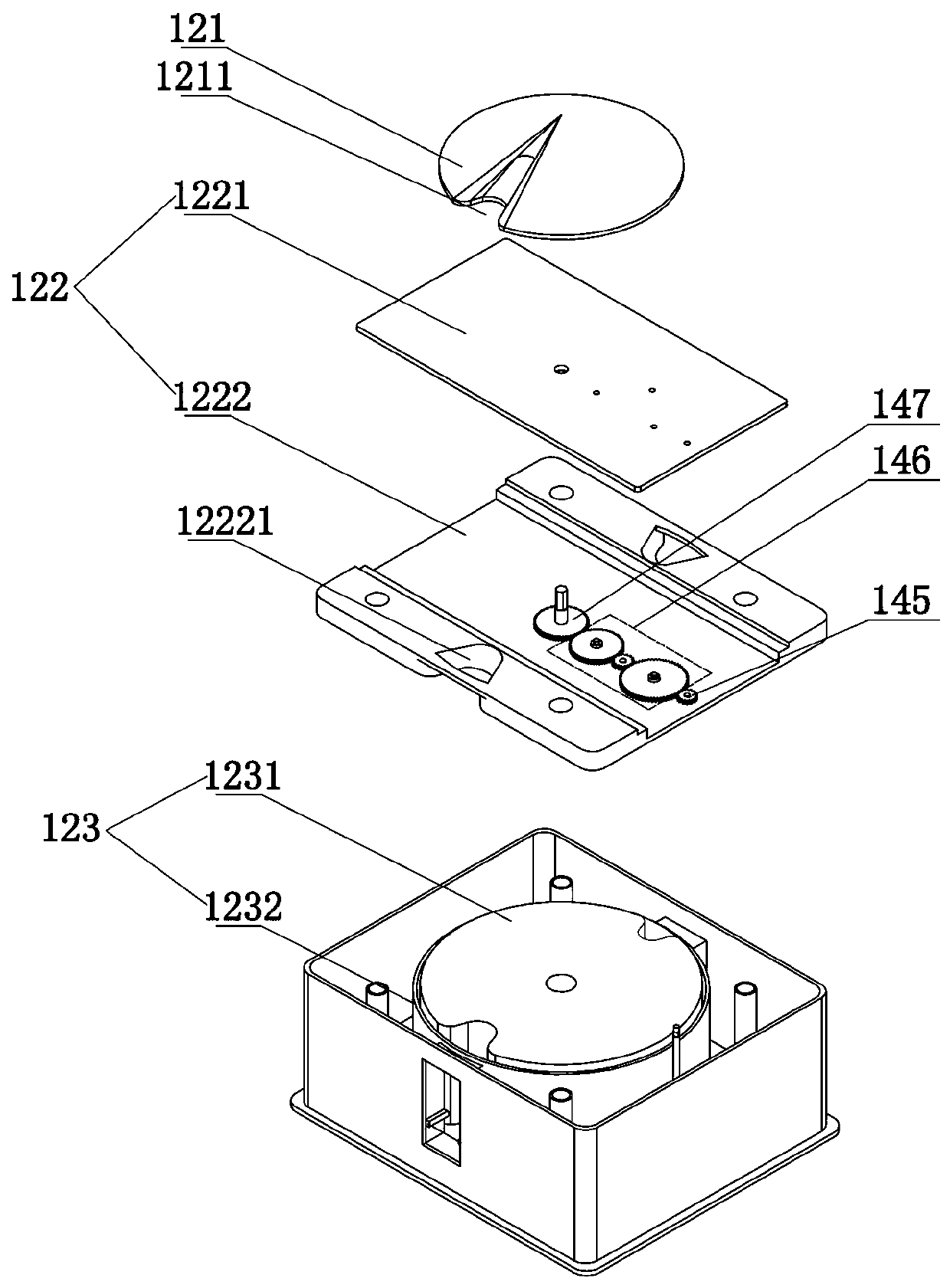

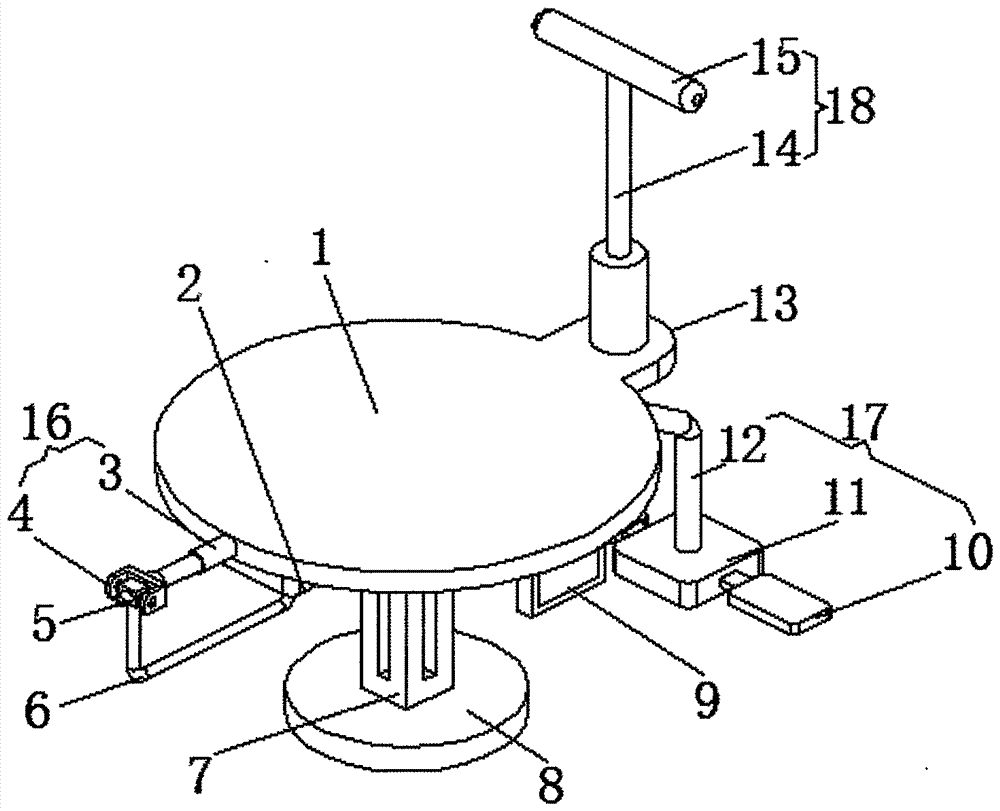

Vial pretreating system for injection room

ActiveCN111196487AOpening closed containersBottle/container closureStructural engineeringInjection rooms

The invention discloses a vial pretreating system for an injection room. The vial pretreating system comprises a vial arranging and storing device, a vial overturning device, a vial uncapping and sterilizing device and a vial conveyer, wherein the vial arranging and storing device is provided with a storing box and a screening base; a reverse vial outlet and an upright vial outlet are formed in the screening base; the upright vial outlet is in butt joint with the vial inlet of the vial overturning device; the vial outlet of the vial overturning device is connected with the reverse vial outletand the vial conveyer; and a clamping conveyer in the vial conveyer is adopted to clamp a vial to pass through the vial uncapping and sterilizing device so as to finish plastic cap opening and aluminium cap sterilizing of the vial.

Owner:JILIN UNIV

Printing head for NANO patterning

InactiveUS20100188449A1Material nanotechnologyAdditive manufacturing apparatusSingle injectionEngineering

Owner:KOREA INST OF MACHINERY & MATERIALS

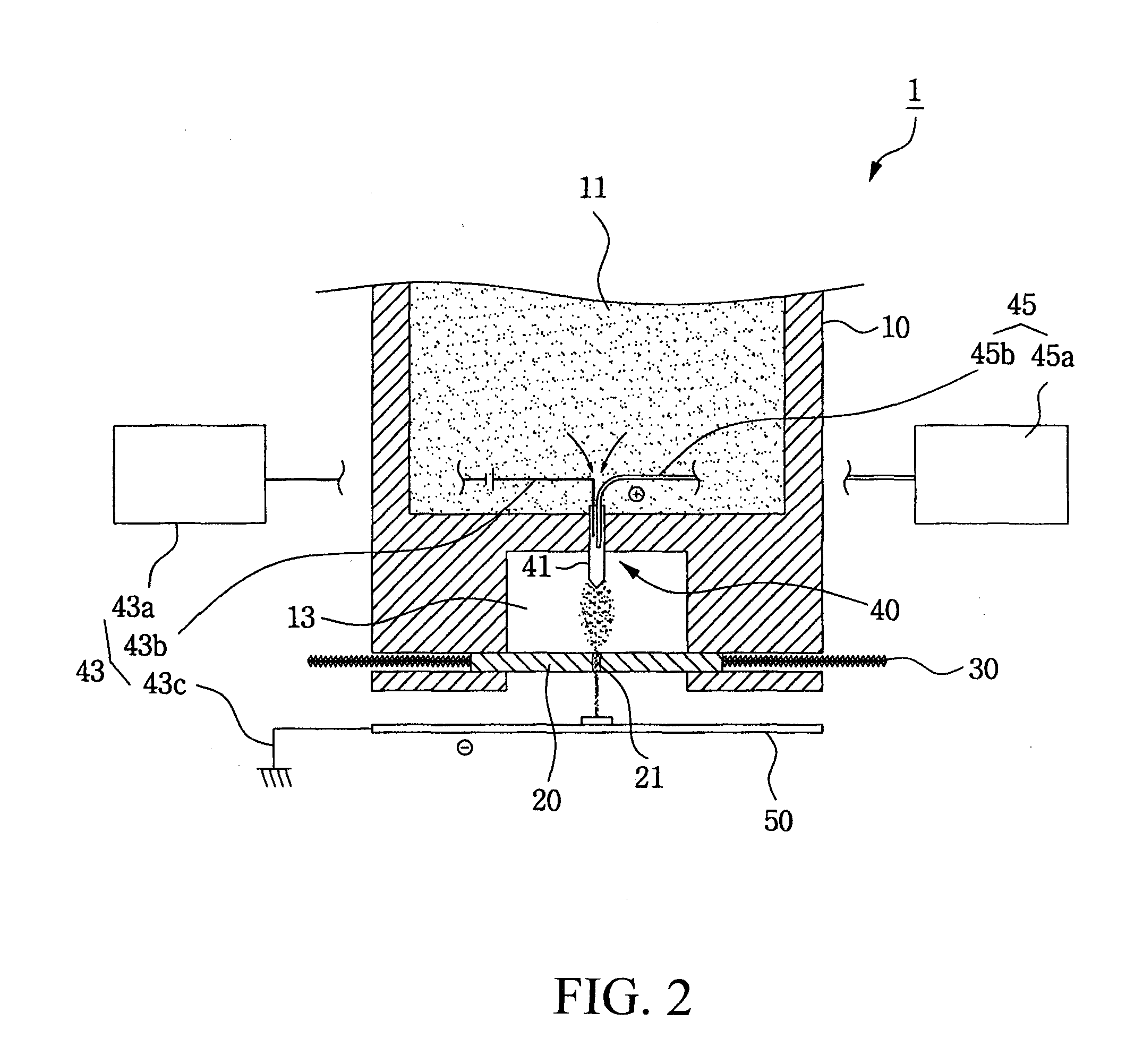

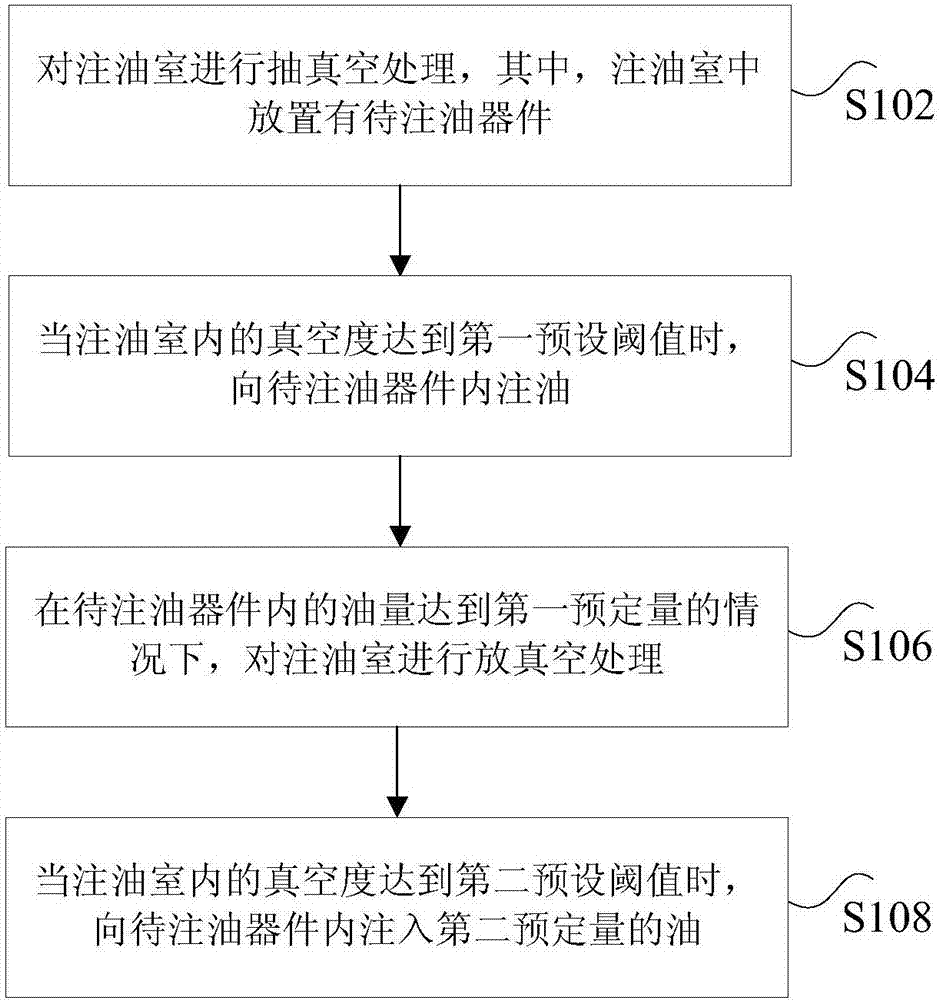

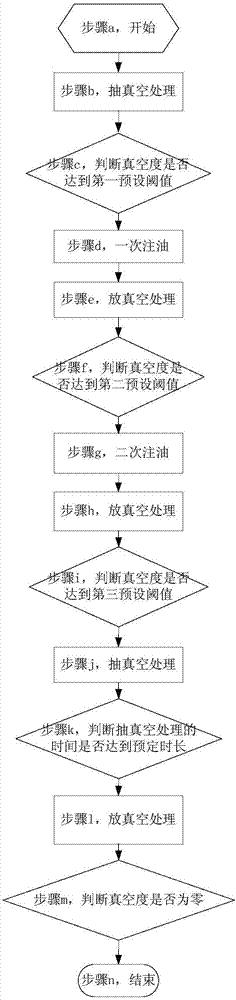

Oil injection control method, oil injector, processor and storage medium

ActiveCN107403691AImprove oil injection accuracyImprove labor productivityThin/thick film capacitorFixed capacitor housing/encapsulationInjection roomsPetroleum engineering

The invention discloses an oil injection control method, an oil injector, a processor and a storage medium. The oil injection control method comprises the following steps: vacuumizing treatment is performed to an oil injection room, wherein a to-be-oil-injected device is placed in the oil injection room; when the vacuum degree in the oil injection room reaches a first preset threshold value, oil injection is performed to the to-be-oil-injected device; when the oil mass in the to-be-oil-injected device reaches a first predetermined amount, vacuum releasing treatment is performed to the oil injection room; and when the vacuum degree in the oil injection room reaches a second preset threshold value, oil of a second predetermined amount is injected to the to-be-oil-injected device. By virtue of the oil injection control method, the technical problem of increasing product loss caused by the manual oil injection mode in the related technology is solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

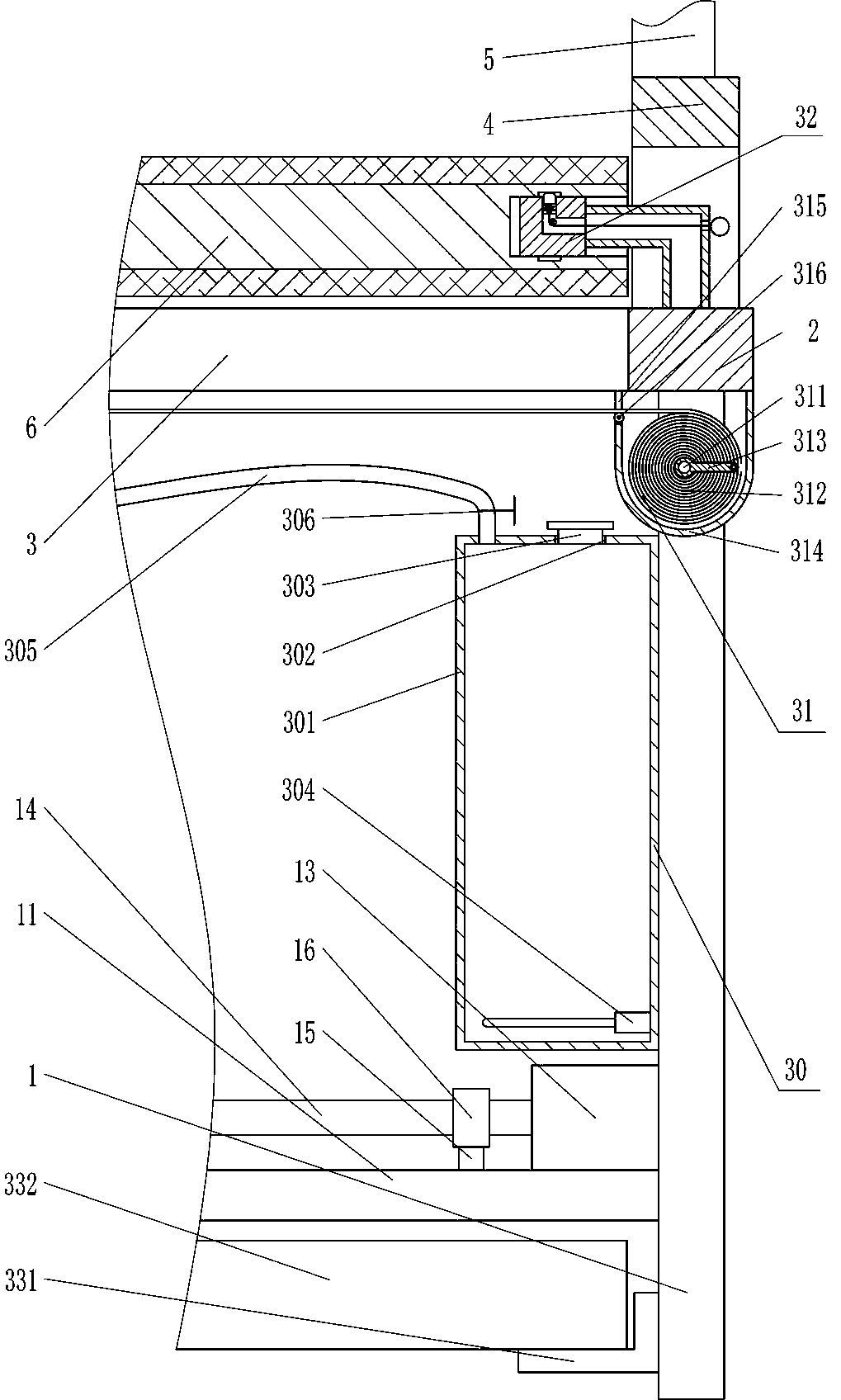

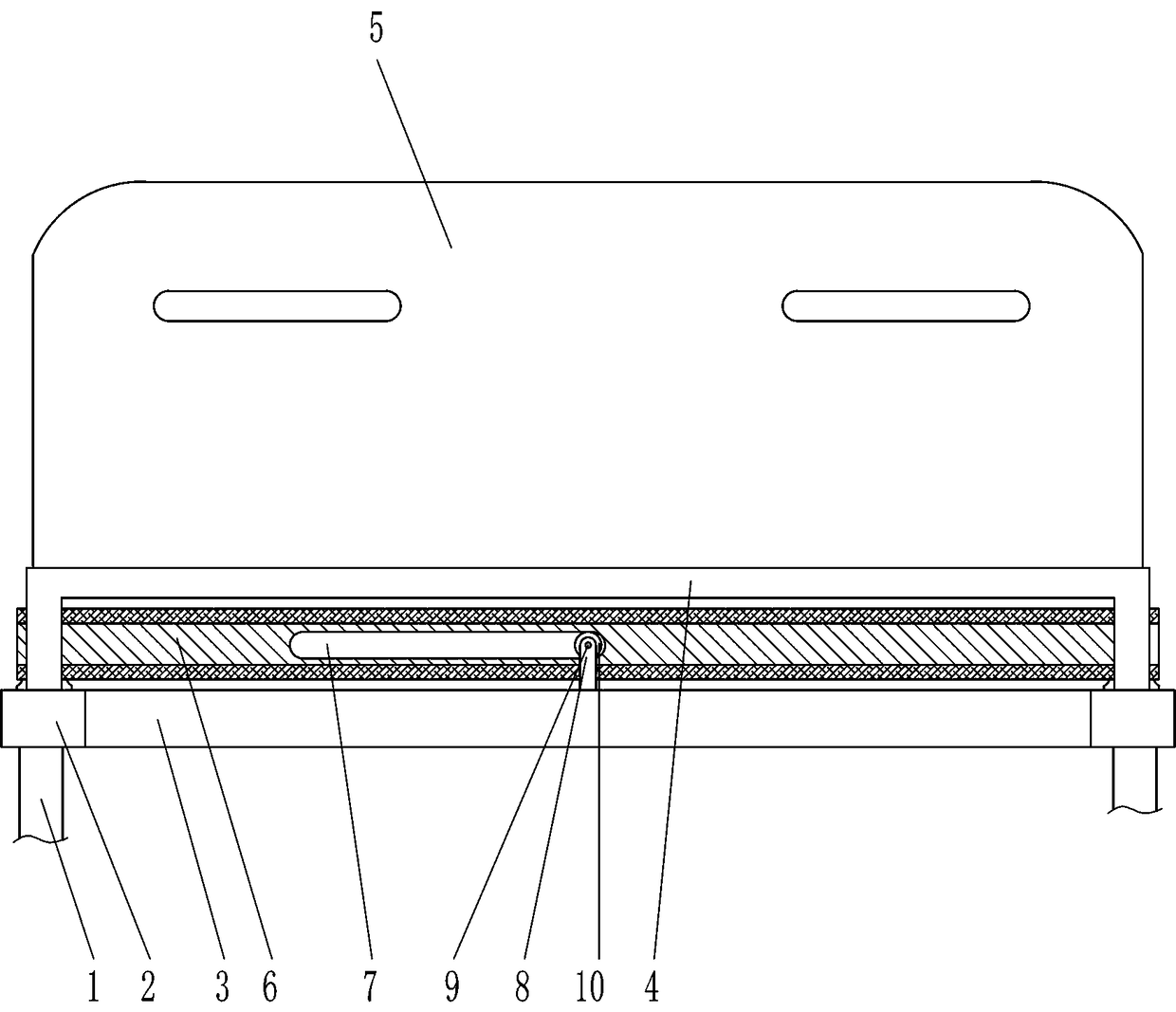

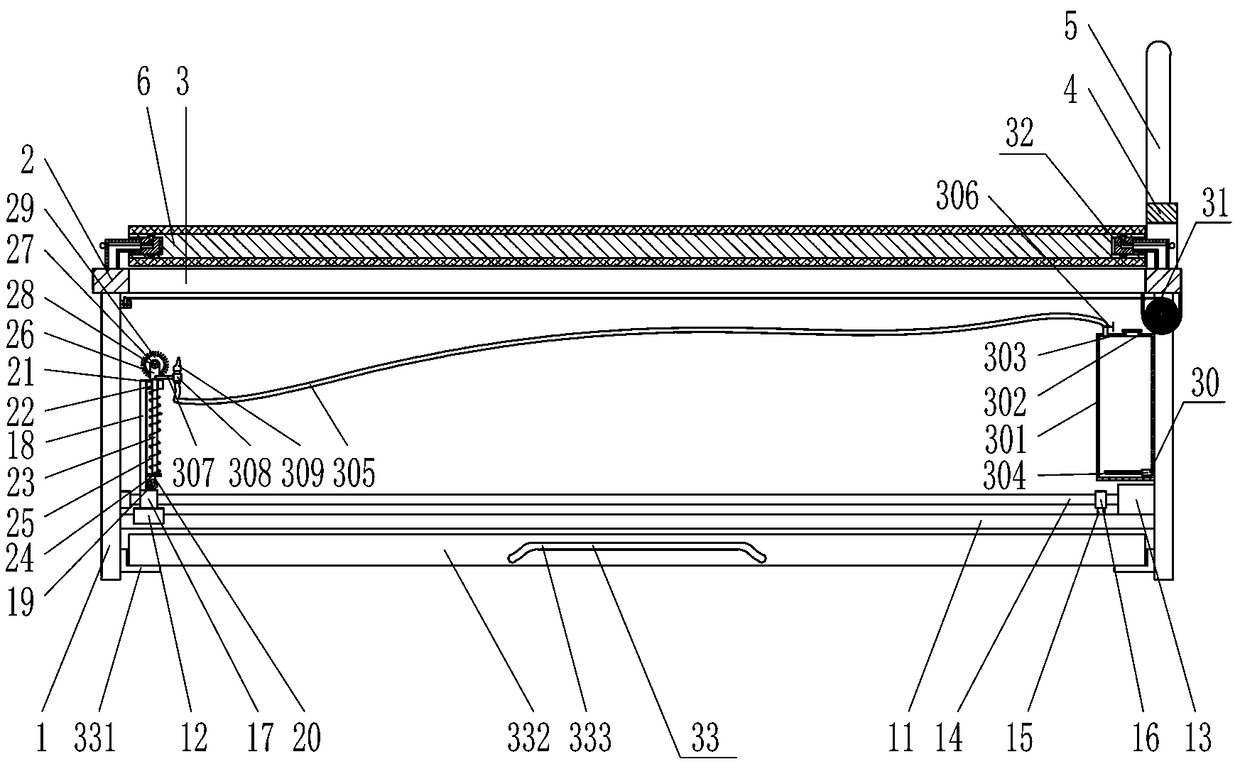

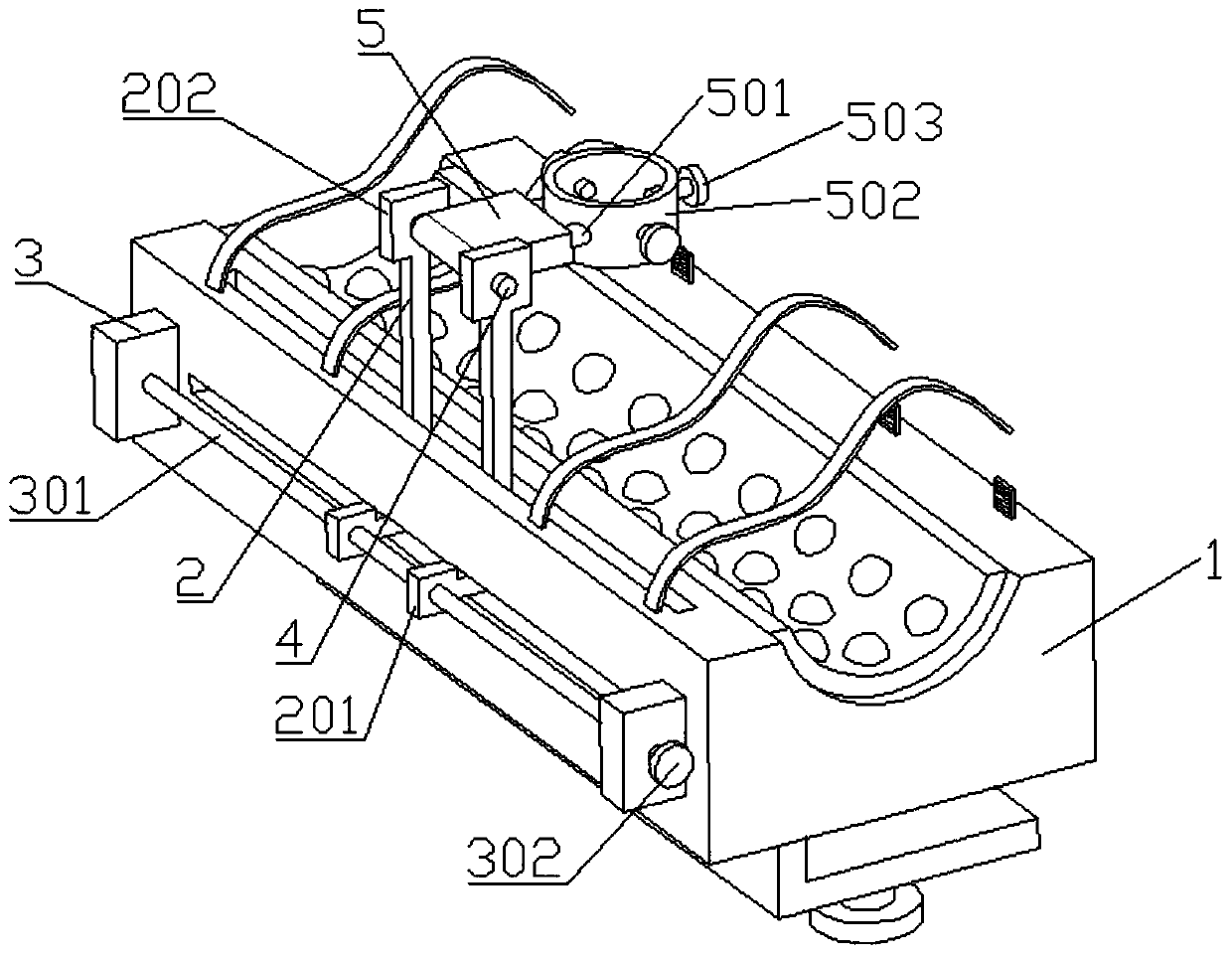

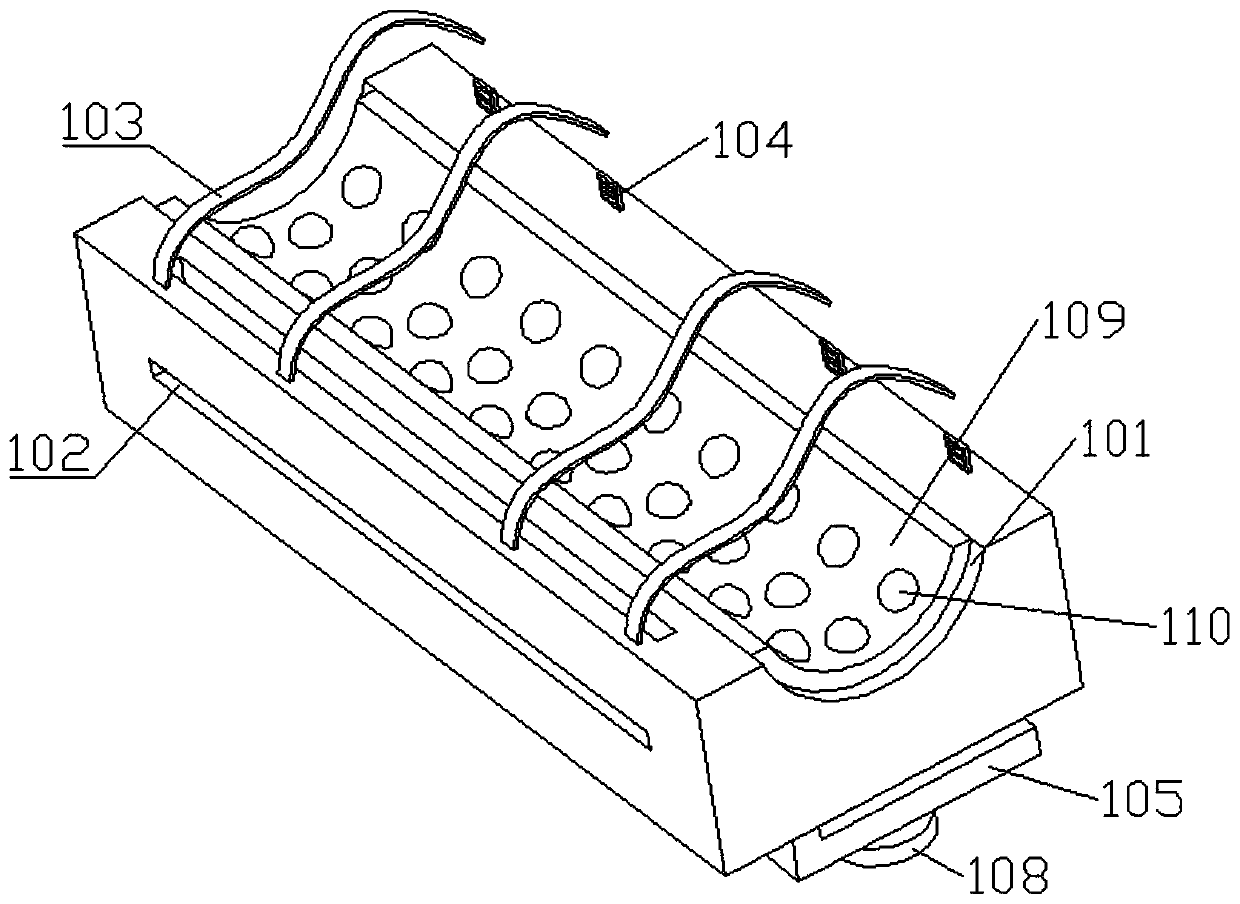

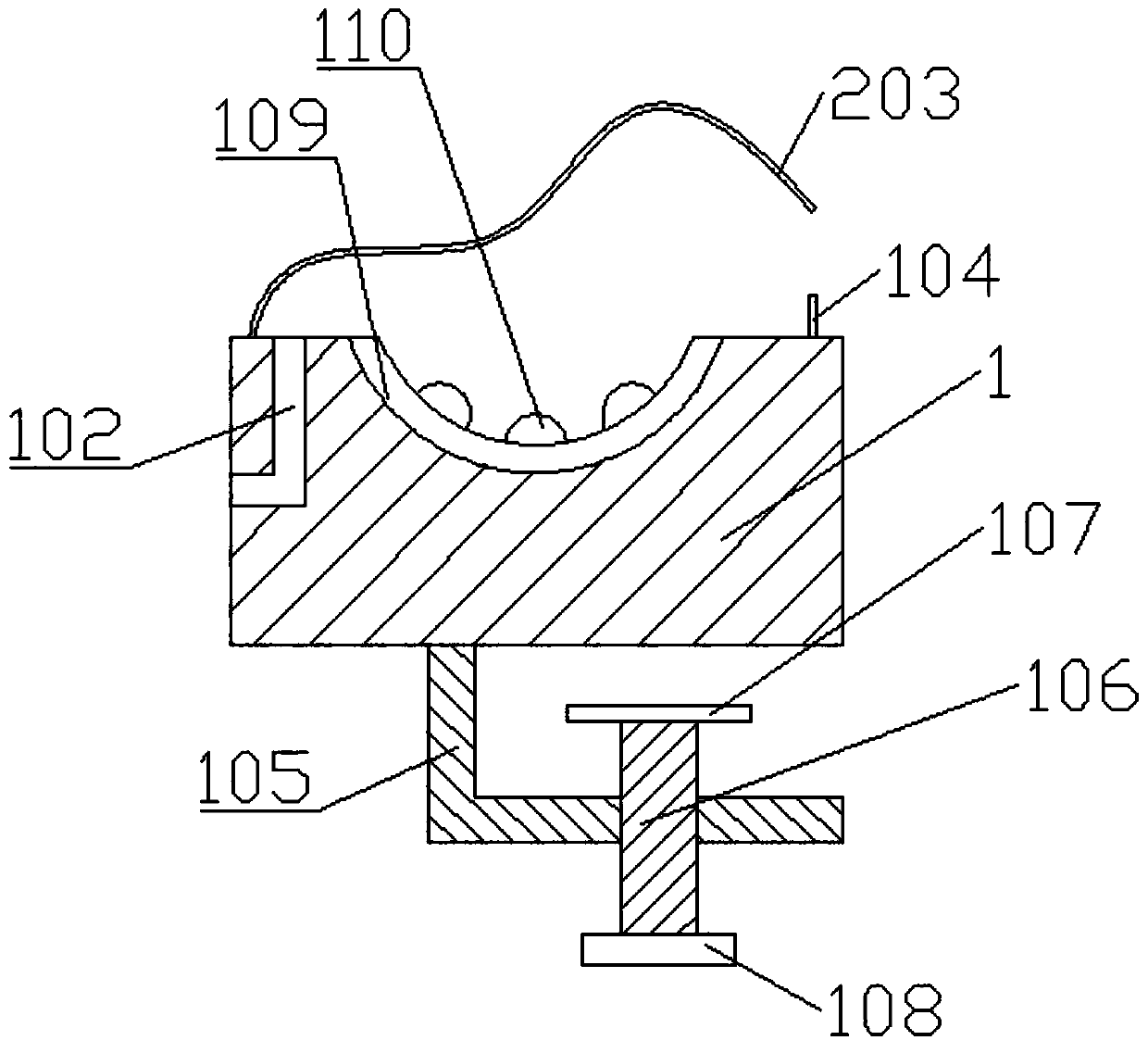

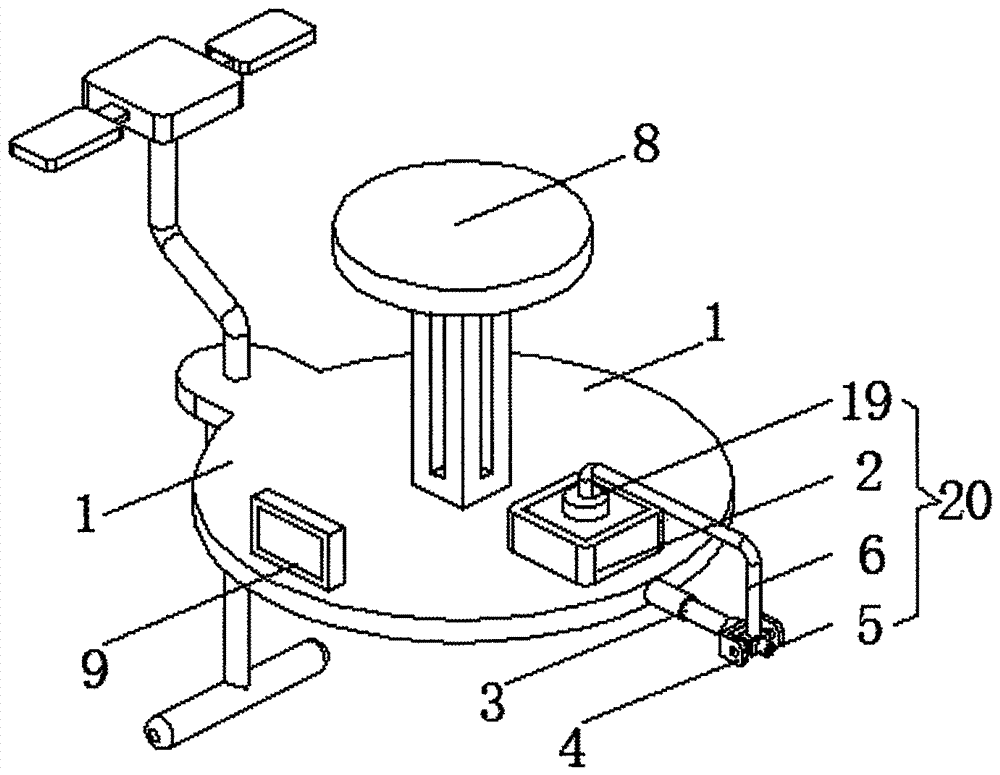

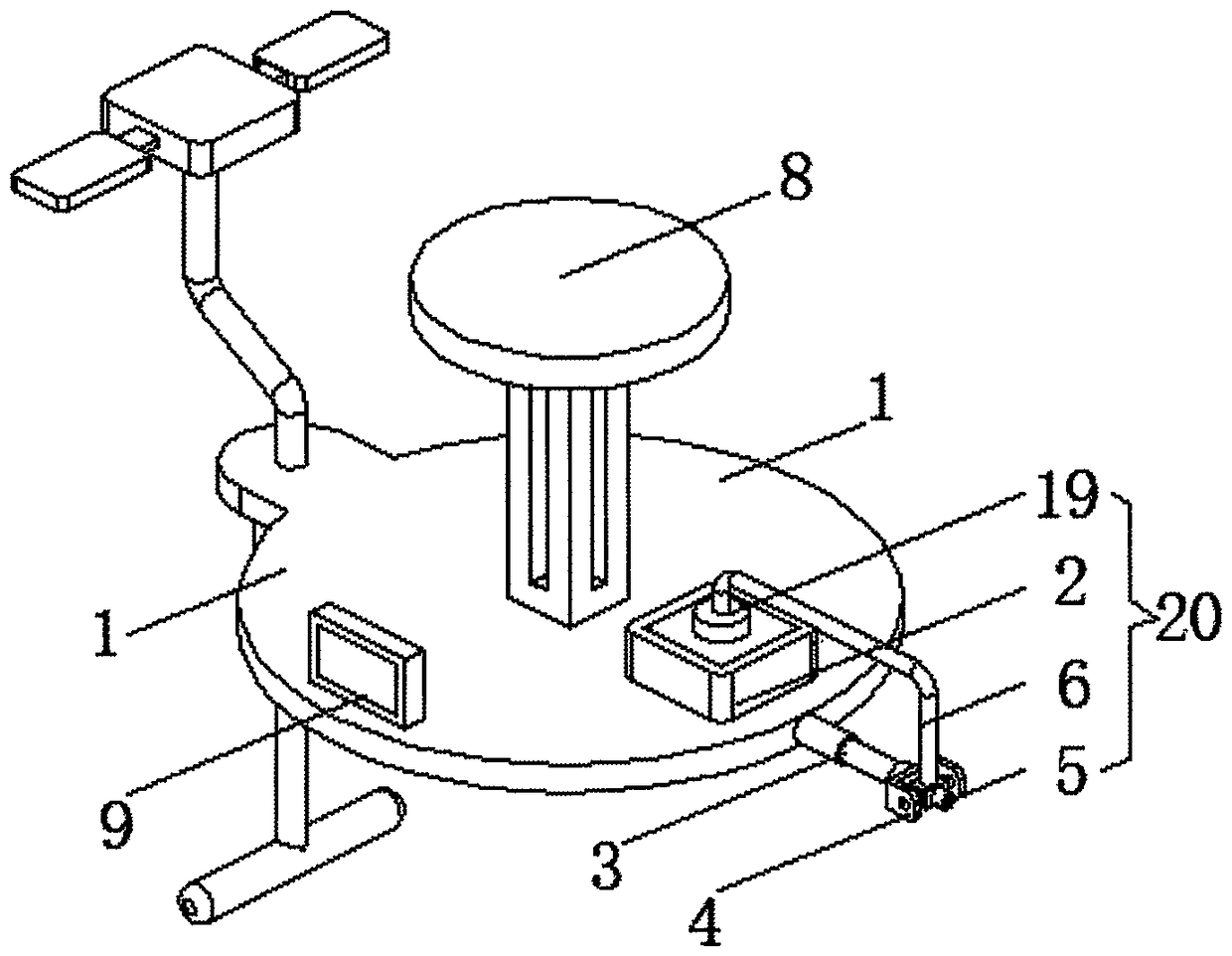

Injection device for nursing in injection room

InactiveCN110141729ANovel structureFunctionalInfusion syringesIntravenous devicesEngineeringInjection device

The invention discloses an injection device for nursing in an injection room. The injection device comprises a placement holder, an L-shaped rod, lug plates, a rotating shaft and a rotating base, wherein an arc holding groove is formed in the upper surface of the placement holder; an L-shaped groove is formed in the left side of the holding groove; the placement holder is fixedly connected with straps and fastening buckles; the L-shaped rod is connected with the inner side of the L-shaped groove in a sliding manner; the left end of the L-shaped rod is fixedly connected with a lug base; the topof the L-shaped rod is fixedly connected with shaft bases; a lead screw is rotatably connected between the lug plates and is meshed with the lug base; the rotating shaft is rotatably connected between the shaft bases; the left end of the rotating base is fixedly connected with the rotating shaft; the right end of the rotating shaft is connected with sliding rods in symmetrical and sliding manners; and the other end of each of the sliding rods is fixedly connected with a corresponding fixed sleeve. The injection device disclosed by the invention has the beneficial effects of novel structure and practical function; through cooperation between the straps and the fastening buckles, the arm is fixed; and through rotation of the rotating shaft and sliding of the sliding rods, a position and anangle of a syringe can be adjusted, and the position also can be adjusted through rotating a first rotating disc, so that the injection device can assist medical personnel to accurately target an injected position.

Owner:李金萍

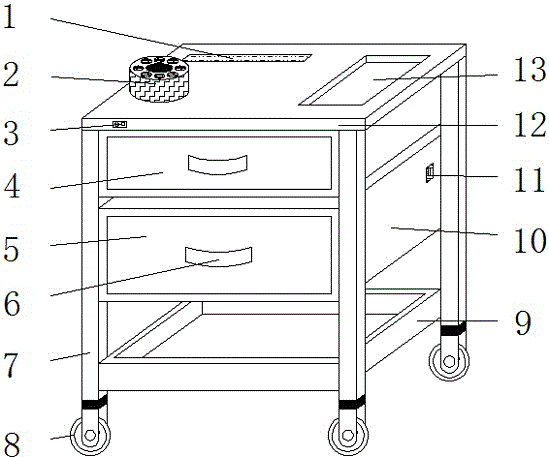

Cart for injection room

InactiveCN106473882AEasy to refrigerateEasy to placeDiagnosticsNursing accommodationTemperature controlEngineering

The invention discloses a cart for an injection room. The cart comprises a supporting seat and supporting legs. A barrel is arranged at the lower left end of the upper surface of the supporting seat, the barrel comprises thermometer placement holes and writing pen placement holes, an ultraviolet lamp is embedded in the upper left end of the upper surface of the supporting seat, a groove is arranged in the right end of the upper surface of the supporting seat, a controller is arranged at the left end of the outer surface of the supporting seat, the controller comprises a temperature control knob and an ultraviolet lamp switch, the supporting legs are arranged at the bottom of the outer surface of the supporting seat, rollers are arranged at the bottom of the outer surface of the supporting legs, a drawer is arranged at upper ends of inner surfaces of the supporting legs, a cabinet seat is arranged in the middle of the inner surfaces of the supporting legs, a battery pack is arranged at the rear end of the inner cavity of the cabinet seat, a storage battery is arranged in the inner cavity of the battery pack, and a refrigeration cabinet is arranged at the front end of the inner cavity of the cabinet seat. The refrigeration cabinet is arranged in the cart for the injection room, convenience in refrigeration of drugs is brought to people, and drug property of the refrigerated drugs is guaranteed.

Owner:林丽芳

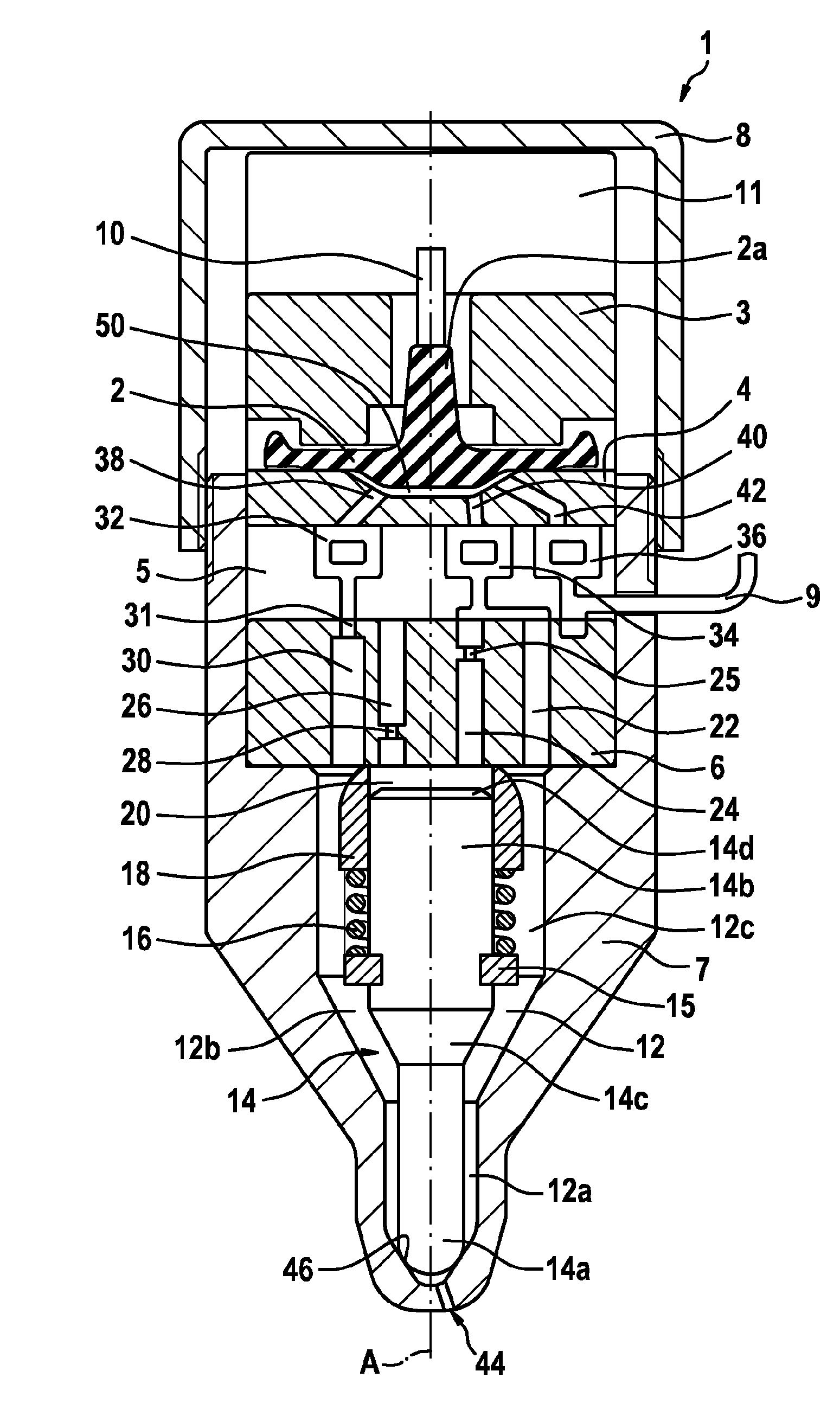

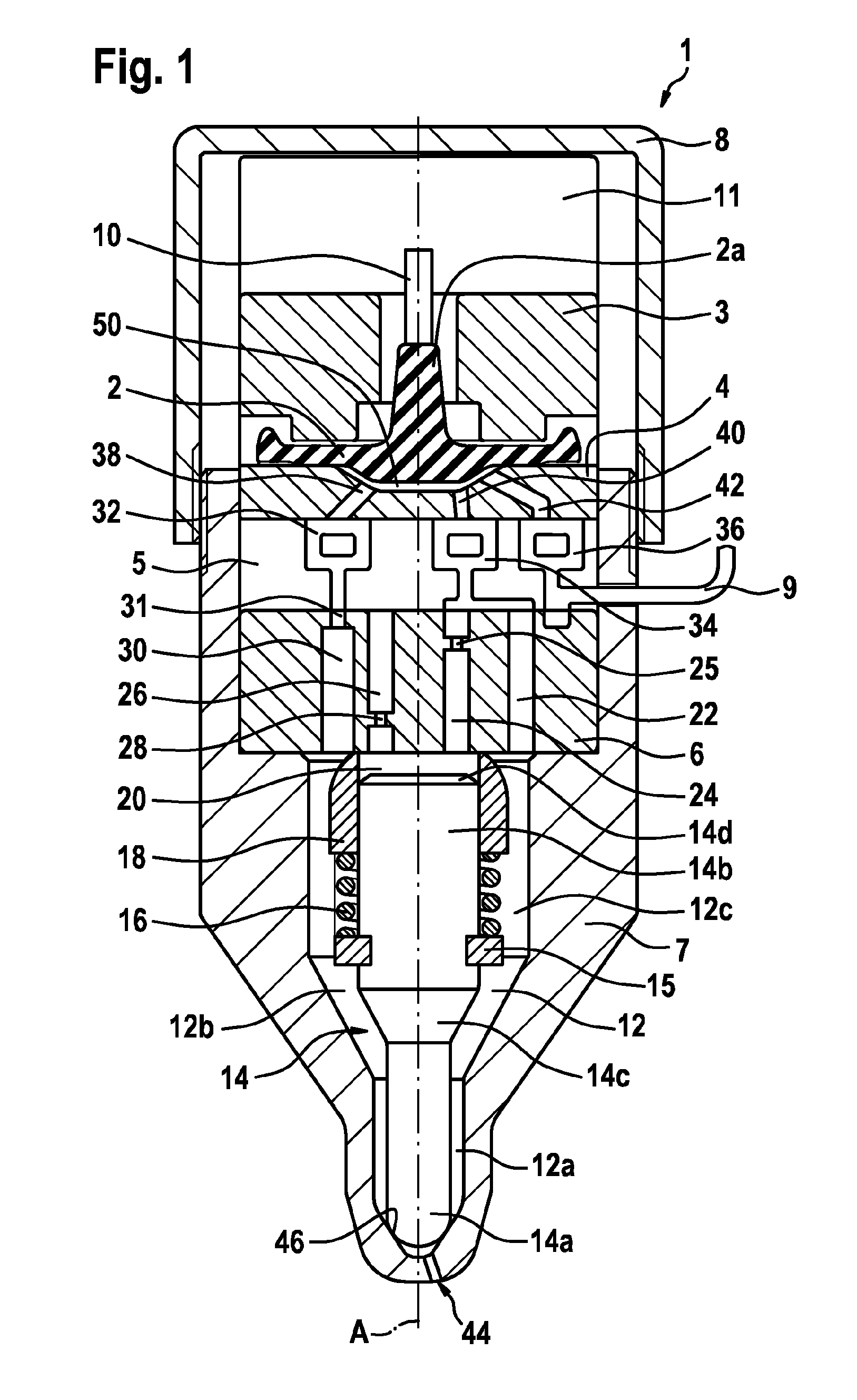

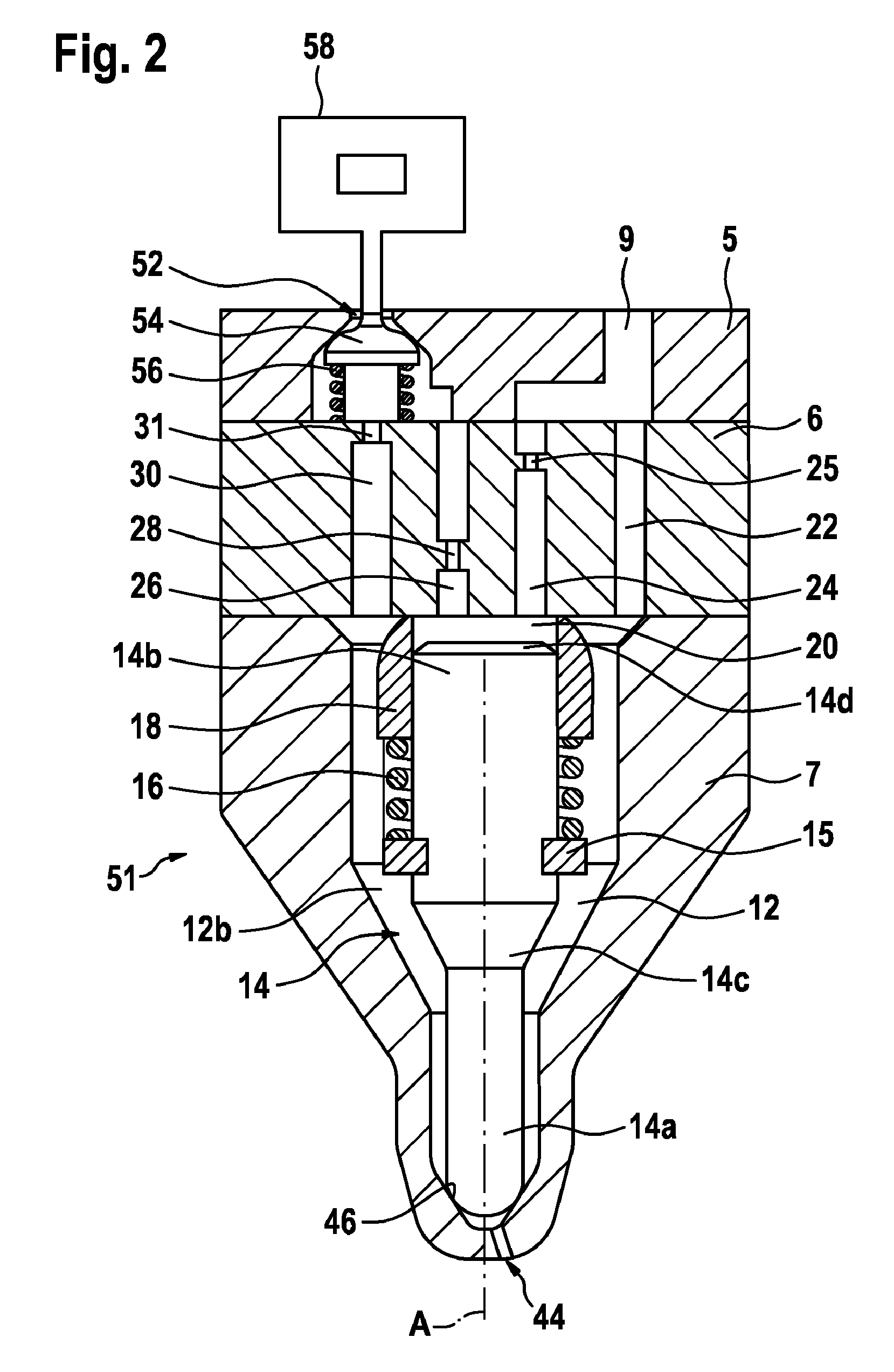

Injection device for introducing a urea solution into the exhaust tract of an internal combustion engine

InactiveUS9279400B2Efficient injectionInexpensive to produceInternal combustion piston enginesExhaust apparatusPressure riseEngineering

The invention relates to an injection device (1), designed in particular for injecting fluid into an exhaust tract of an internal combustion engine, having a valve needle (14), an injection chamber (12) having at least one injection opening (44), and a control chamber (20). The injection device (1) is designed such that a pressure differential between the injection chamber (12) and the control chamber (20) brings about a displacement of the valve needle (14) between an open position in which a fluid flow through the injection opening (44) from the injection chamber (12) is released, and a closed position, in which the injection opening (44) is closed off. The injection chamber (22) and the control chamber (20) are hydraulically connected to an inlet (40, 42; 9), such that a pressure rise in the inlet (40, 42; 9) results in a pressure rise in the injection chamber (12), and a pressure rise in the control chamber (20) delayed in time relative to the pressure rise in the injection chamber (12), and said pressure differential brings about a displacement of the valve needle (14) from the closed position into an open position.

Owner:ROBERT BOSCH GMBH

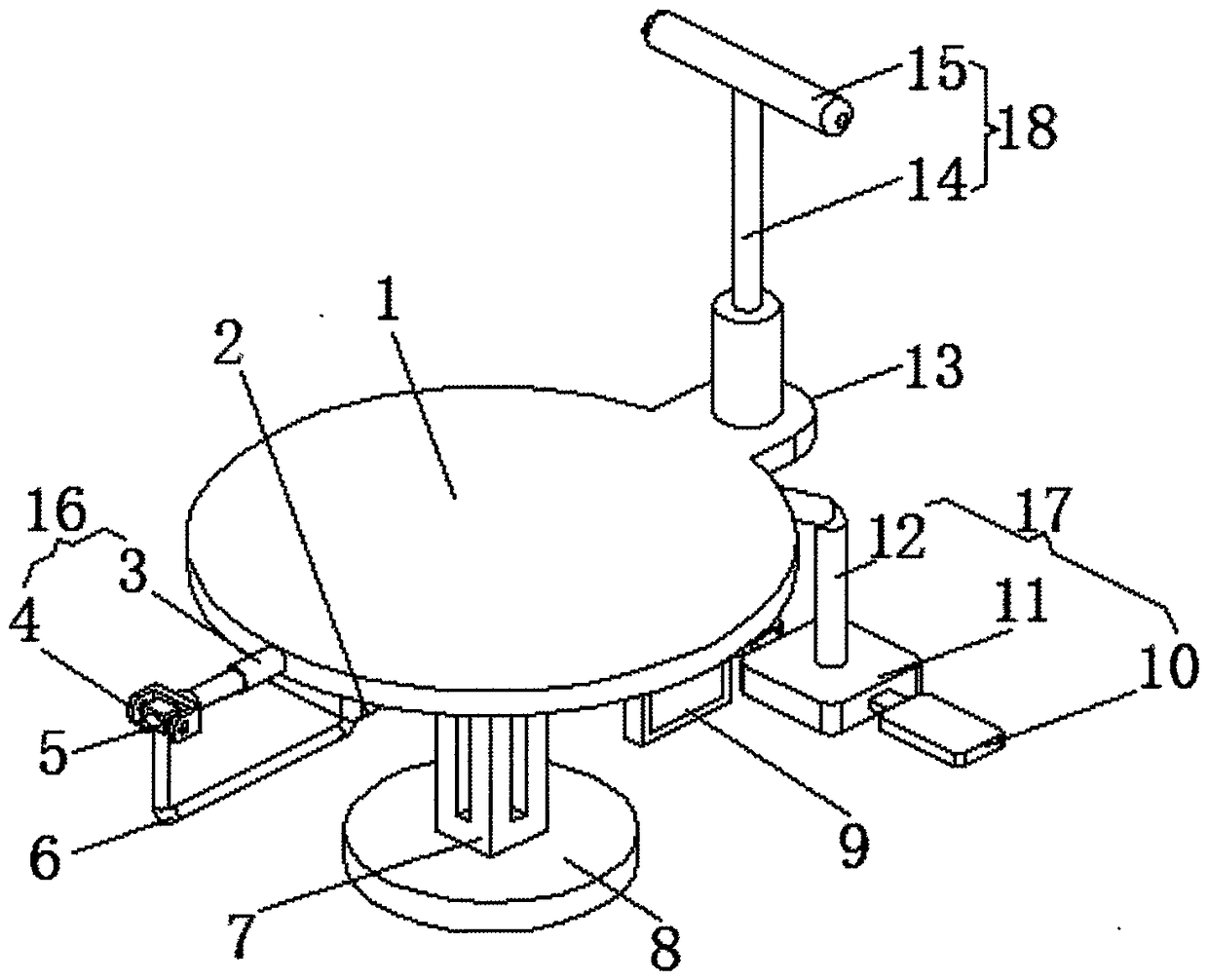

Multifunctional chair for injection room patients

ActiveCN107242956AReduce the burden onReduce tensionOperating chairsDental chairsEngineeringWorkload

The invention discloses a multifunctional chair for injection room patients. The chair comprises a seat plate. A supporting frame is fixed to the middle of the bottom end of the seat plate. A circular base is welded to one end of the supporting frame. A connecting lug is welded to the position, corresponding to the front side of a human body, of the seat plate. A supporting device is arranged at the bottom end of the connecting lug. A laying mechanism is installed at the top end of the connecting lug. A disinfecting device is installed at the position, corresponding to a human hip, of the seat plate through a connecting mechanism. A control switch set is arranged at the position, corresponding to a human right hand, of the bottom of the seat plate and electrically connected with an external power supply. The chair has capacity for laying and automatic disinfecting and is diversified in function; the human body is supported by the laying mechanism instead of two hands, burdens on patients are relieved, a traditional disinfecting mode is replaced with the non-contact disinfecting device, the inner nervous sense of patients is reduced, injection work is easy, and meanwhile workloads of medical staff are reduced.

Owner:张艳丽

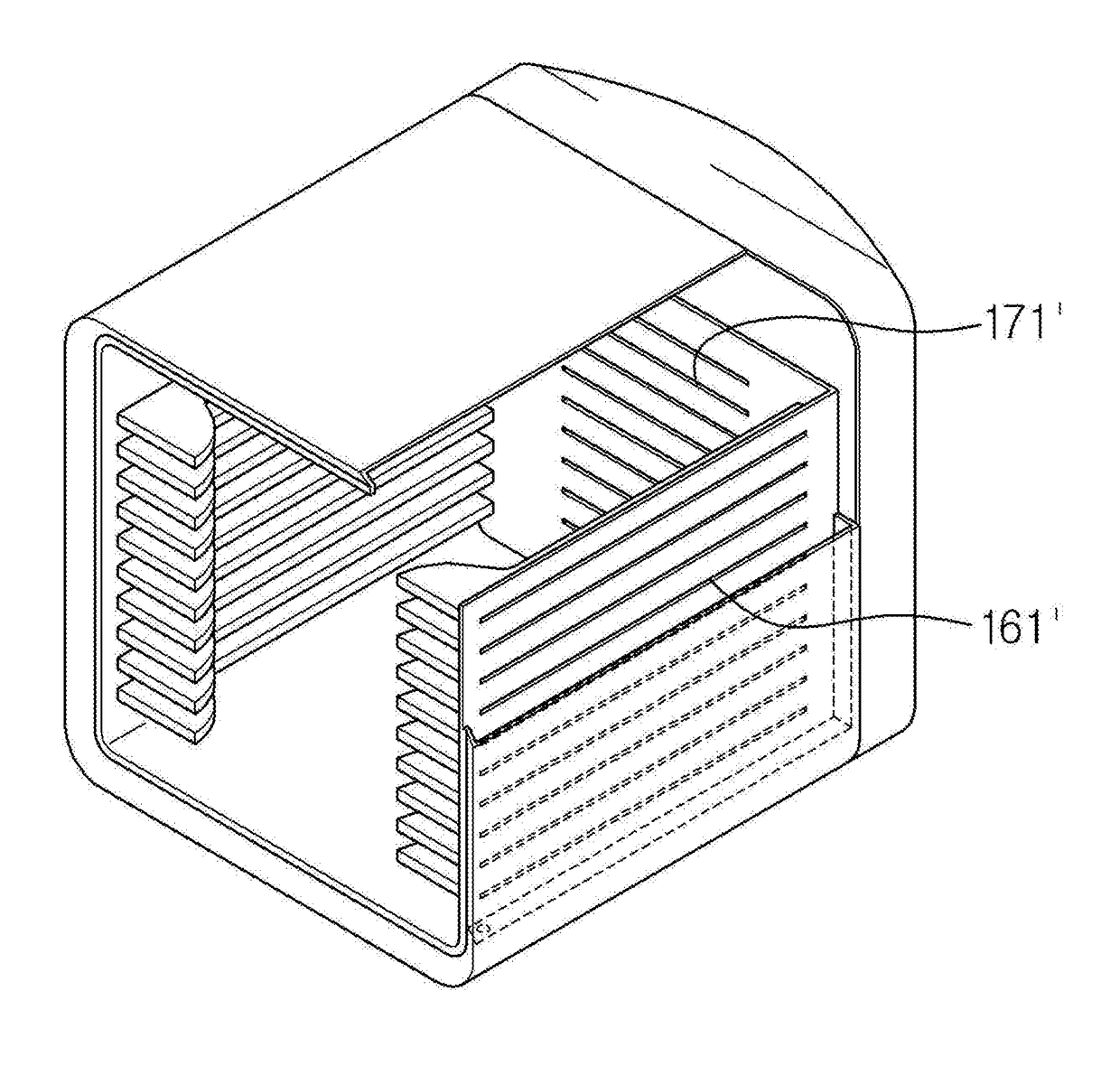

Wafer storage container

ActiveUS20180261483A1Efficient removalSmooth exhaustSemiconductor/solid-state device manufacturingEngineeringInjection rooms

The present invention relates to a wafer storage container, more particularly, relates to a wafer storage container wherein the space of the wafer storage container is divided into the spaces, namely a storage room, a gas injection room, and a gas exhausting room, which are independent and separate from each other, so when the wafer storage container is transported to the load port and being coupled therewith, the purge gas is injected / exhausted through the separating walls inside the storage room, thereby efficiently removing the remaining fumes on the surface of the wafer.

Owner:PICO & TERA CO LTD +1

Oil injection room provided with oil injection equipment

InactiveCN106216153AReduce pollutionEasy to collect and processLiquid surface applicatorsCoatingsInjection equipmentAir pollution

The invention discloses an oil injection room provided with oil injection equipment. The oil injection equipment is arranged in the oil injection room. An oil injection nozzle is arranged on the oil injection device. A water curtain room is mounted on one side of the oil injection room. Three connectors are arranged on the water curtain room and connected with an air-induced pipe, a water pump and an oil outlet pipe correspondingly. The air-induced pipe is connected with a fan. The oil outlet pipe is connected with a water tank. The water pump is connected with the water curtain room and the water tank through water pipes correspondingly. According to the oil injection room provided with the oil injection equipment, injected oil is sucked into the water curtain room through the fan and then subjected to sedimentation through water, the injected oil is delivered into the water tank through the oil outlet pipe and then discharged out of the water tank in a centralized mode, in this way, air pollution in the construction process can be effectively reduced when the oil injection room is in use, and the coating quality and working efficiency are improved. Emission pollutants can be collected and treated easily, mounting is flexible, and the oil injection room is suitable for coating of the surfaces of various rotary bodies.

Owner:南京明杰科技有限公司

A cold fireplace and continuous production method for preparing graphene by CVD method

Owner:WUXI GRAPHENE FILM +1

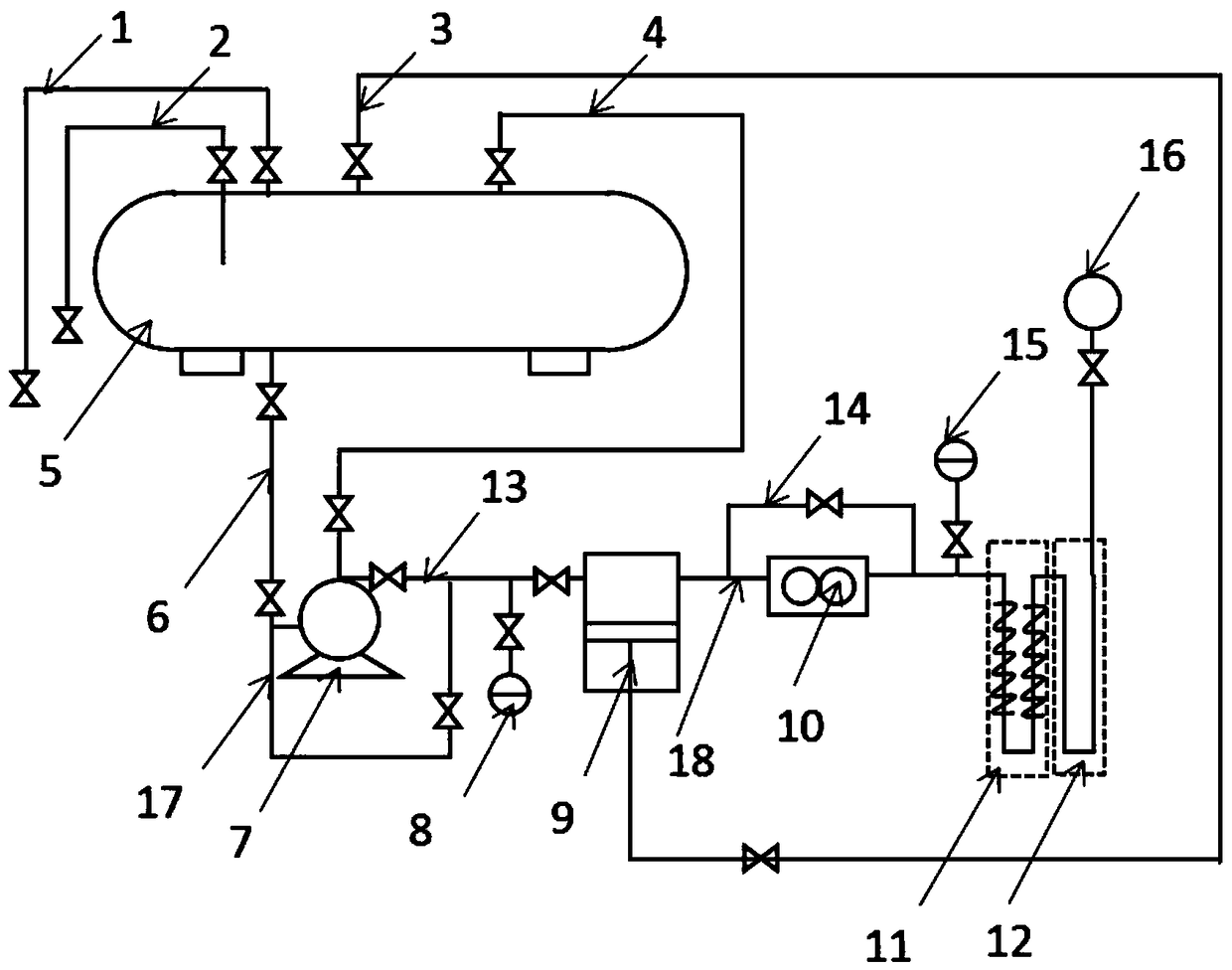

Skid-mounted gas injection device

PendingCN109209313AEasy to useFlexible moving processOther gas emission reduction technologiesInsulationEngineeringInjection well

The invention discloses a skid-mounted gas injection device, which comprises a carbon dioxide storage tank, a liquid feeding pump, a pressure injection pump and a heating pipeline, wherein the carbondioxide storage tank comprises a vehicle filling gaseous phase pipe, a vehicle filling liquid phase pipe and a liquid feeding pump liquid inlet pipe, the vehicle filling gaseous phase pipe and the vehicle filling liquid phase pipe are connected with an external mobile tank vehicle, the liquid feeding pump liquid inlet pipe is connected with a liquid feeding pump, a liquid feeding pump liquid outlet pipe is arranged between the liquid feeding pump and the pressure injection pump, a pressure injection pump liquid outlet pipe is arranged between the pressure injection pump and the heating pipeline, the heating pipeline is connected with a pressure-relief injection well, and the carbon dioxide storage tank, the liquid feeding pump, the pressure injection pump and the heating pipeline are arranged on a skid carrier. Through arranging the carbon dioxide storage tank, the liquid feeding pump, the pressure injection pump and the heating pipeline on the skid carrier, the skid-mounted gas injection device is convenient to use and flexible to move, saves the construction of a gas injection room and reduces the cost; and the heating pipeline is arranged for rising the temperature of the carbondioxide at an outlet of the pressure injection pump, thereby avoiding shrinkage and fracture of the downhole oil casing tubular column, and ensuring safe production.

Owner:JIANGSU HUAYANG LIQUID CARBON CO LTD

A multi-functional seat for patients in an injection room

ActiveCN107242956BReduce the burden onReduce tensionOperating chairsDental chairsEngineeringControl switch

The invention discloses a multifunctional chair for injection room patients. The chair comprises a seat plate. A supporting frame is fixed to the middle of the bottom end of the seat plate. A circular base is welded to one end of the supporting frame. A connecting lug is welded to the position, corresponding to the front side of a human body, of the seat plate. A supporting device is arranged at the bottom end of the connecting lug. A laying mechanism is installed at the top end of the connecting lug. A disinfecting device is installed at the position, corresponding to a human hip, of the seat plate through a connecting mechanism. A control switch set is arranged at the position, corresponding to a human right hand, of the bottom of the seat plate and electrically connected with an external power supply. The chair has capacity for laying and automatic disinfecting and is diversified in function; the human body is supported by the laying mechanism instead of two hands, burdens on patients are relieved, a traditional disinfecting mode is replaced with the non-contact disinfecting device, the inner nervous sense of patients is reduced, injection work is easy, and meanwhile workloads of medical staff are reduced.

Owner:张艳丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com