A method for improving the shear performance of carbon/carbon-lithium aluminum silicon joints

A lithium-aluminum-silicon and performance technology, which is applied in the field of preparation of carbon/carbon-lithium-aluminum-silicon joints, can solve problems such as weak interface between the modified layer and the intermediate layer, so as to solve the weak interface, increase the effective connection area, and improve the Effective connection area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Cut the 2D C / C composite material into a flat plate of 30mm×30mm×4mm, polish it with 100# silicon carbide water sandpaper, clean it ultrasonically with absolute ethanol and deionized water for 30 minutes, and then place it in a blast drying oven at 100°C Dry in medium for more than 4 hours for later use.

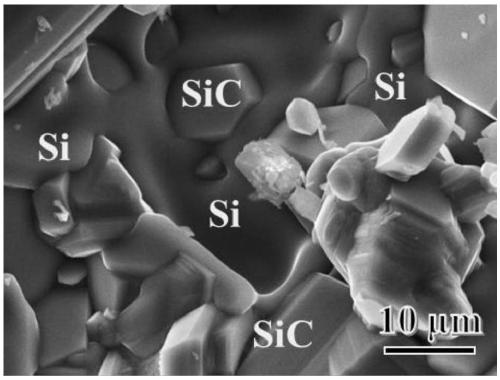

[0031] Weigh 100g of silicon powder, 10g of carbon powder, and 5g of alumina powder, and use a roller ball mill to mix them evenly; then embed the C / C composite material in a graphite crucible with mixed powder, and seal it with graphite paper; The crucible was placed in a high-temperature reaction graphitization furnace, and under the protection of argon, the furnace temperature was raised to 1700°C at a rate of 20°C / min, and then to 2300°C at a rate of 5°C / min, and kept for 1 hour. , and then turn off the power and cool down to room temperature naturally to obtain a C / C composite material modified by silicon-based ceramic coating, the surface morphology of which is ...

Embodiment example 2

[0035] Cut the 2D C / C composite material into a flat plate of 30mm×30mm×4mm, polish it with 100# silicon carbide water sandpaper, clean it ultrasonically with absolute ethanol and deionized water for 30 minutes, and then place it in a blast drying oven at 100°C Dry in medium for more than 4 hours for later use.

[0036] Weigh 100g of silicon powder, 10g of carbon powder, and 5g of alumina powder, and use a roller ball mill to mix them evenly; then embed the C / C composite material in a graphite crucible with mixed powder, and seal it with graphite paper; The crucible was placed in a high-temperature reaction graphitization furnace, and under the protection of argon, the furnace temperature was raised to 1700°C at a rate of 20°C / min, and then to 2300°C at a rate of 5°C / min, and kept for 1 hour. , and then turn off the power and naturally cool to room temperature to obtain a silicon-based ceramic modified C / C composite material.

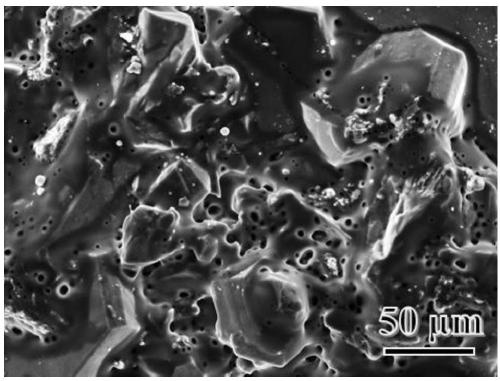

[0037] The above coating sample was placed in a ...

Embodiment example 3

[0041] Cut the 2D C / C composite material into a flat plate of 30mm×30mm×4mm, polish it with 100# silicon carbide water sandpaper, clean it ultrasonically with absolute ethanol and deionized water for 30 minutes, and then place it in a blast drying oven at 100°C Dry in medium for more than 4 hours for later use.

[0042] Weigh 100g of silicon powder, 10g of carbon powder, and 5g of alumina powder, and use a roller ball mill to mix them evenly; then embed the C / C composite material in a graphite crucible with mixed powder, and seal it with graphite paper; The crucible was placed in a high-temperature reaction graphitization furnace, and under the protection of argon, the furnace temperature was raised to 1700°C at a rate of 20°C / min, and then to 2300°C at a rate of 5°C / min, and kept for 1 hour. , and then turn off the power and naturally cool to room temperature to obtain a silicon-based ceramic modified C / C composite material.

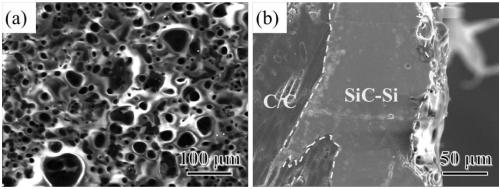

[0043] The above coating sample was placed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com