A powder core wire material for arc spraying with high bonding strength and preparation method thereof

A powder core wire, bonding strength technology, applied in coating, fusion spraying, metal material coating process and other directions, can solve the problems of low service life, corrosion and wear of acid and alkali oxides, strong erosion, etc., to improve service life , strong adhesion, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

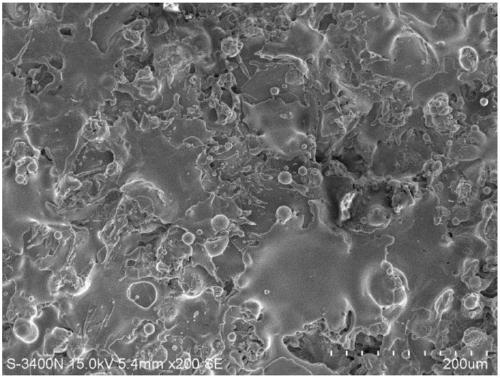

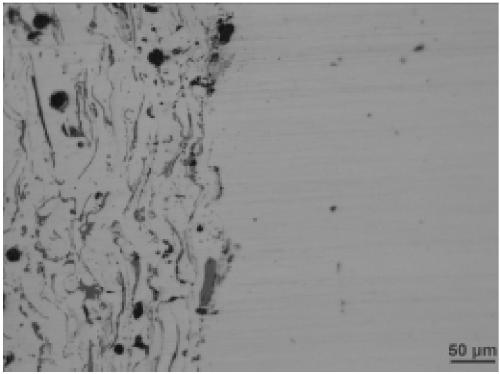

Image

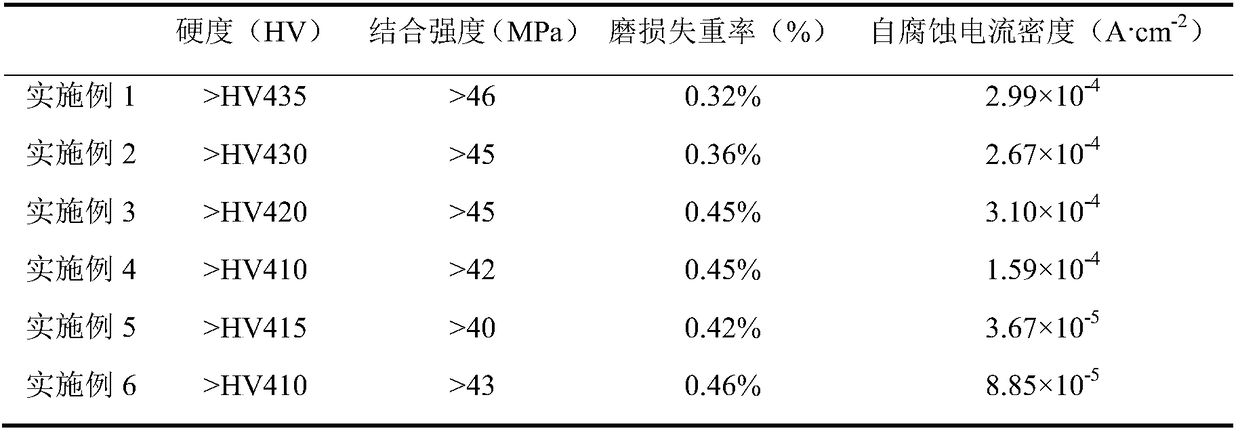

Examples

Embodiment 1

[0022] According to one aspect of the present invention, this embodiment provides a powder core wire material for arc spraying with high bonding strength, the powder core wire material is composed of a cladding layer and a powder core, and the cladding layer is austenitic stainless steel A narrow strip, the mass percentage of the powder core in the total wire material is 45%, and the austenitic stainless steel narrow strip is made of 304 stainless steel;

[0023] The powder core is mixed by the following powder raw materials in mass percentage: WC powder 25%, TiC powder 15%, TiB powder 2 Powder 12%, Cr 3 C 2 10% of Ni powder, 10% of Ni powder, 12% of Cr powder, 10% of Co powder, and the balance is Fe powder. The WC powder, TiC powder, TiB powder used in the present invention 2 Powder and Cr 3 C 2 The powder particle size of the powder is 40 μm, and the powder particle size of the Ni powder, Cr powder, Co powder, and Fe powder is 20 μm.

[0024] According to another aspect...

Embodiment 2

[0030] According to one aspect of the present invention, this embodiment provides a powder core wire material for arc spraying with high bonding strength, the powder core wire material is composed of a cladding layer and a powder core, and the cladding layer is austenitic stainless steel Narrow strip, the mass percentage of the powder core in the total wire material is 42%, and the narrow strip of austenitic stainless steel adopts 304L stainless steel;

[0031] The powder core is mixed by the following powder raw materials in mass percentage: WC powder 30%, TiC powder 12%, TiB powder 2 Powder 8%, Cr 3 C 29% of Ni powder, 15% of Ni powder, 12% of Cr powder, 8% of Co powder, and the balance is Fe powder. The WC powder, TiC powder, TiB powder used in the present invention 2 Powder and Cr 3 C 2 The powder particle size of the powder is 50 μm, and the powder particle size of the Ni powder, Cr powder, Co powder, and Fe powder is 30 μm.

[0032] According to another aspect of th...

Embodiment 3

[0038] According to one aspect of the present invention, this embodiment provides a powder core wire material for arc spraying with high bonding strength, the powder core wire material is composed of a cladding layer and a powder core, and the cladding layer is austenitic stainless steel A narrow strip, the mass percentage of the powder core in the total wire material is 38%, and the austenitic stainless steel narrow strip is 316L stainless steel;

[0039] The powder core is mixed by the following powder raw materials in mass percentage: WC powder 30%, TiC powder 10%, TiB powder 2 Powder 6%, Cr 3 C 2 Powder 9%, Ni powder 15%, Cr powder 15%, Co powder 8%, the balance is Fe powder, WC powder, TiC powder, TiB powder used in the present invention 2 Powder and Cr 3 C 2 The powder particle size of the powder is 30 μm, and the powder particle size of the Ni powder, Cr powder, Co powder, and Fe powder is 18 μm.

[0040] According to another aspect of the present invention, this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com