Right wefting insertion device for high-speed towel rapier loom

A technology of towel loom and right weft insertion, which is applied to looms, textiles, textiles and papermaking, etc., can solve problems such as troublesome maintenance, and achieve the effects of saving production costs, good reliability, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

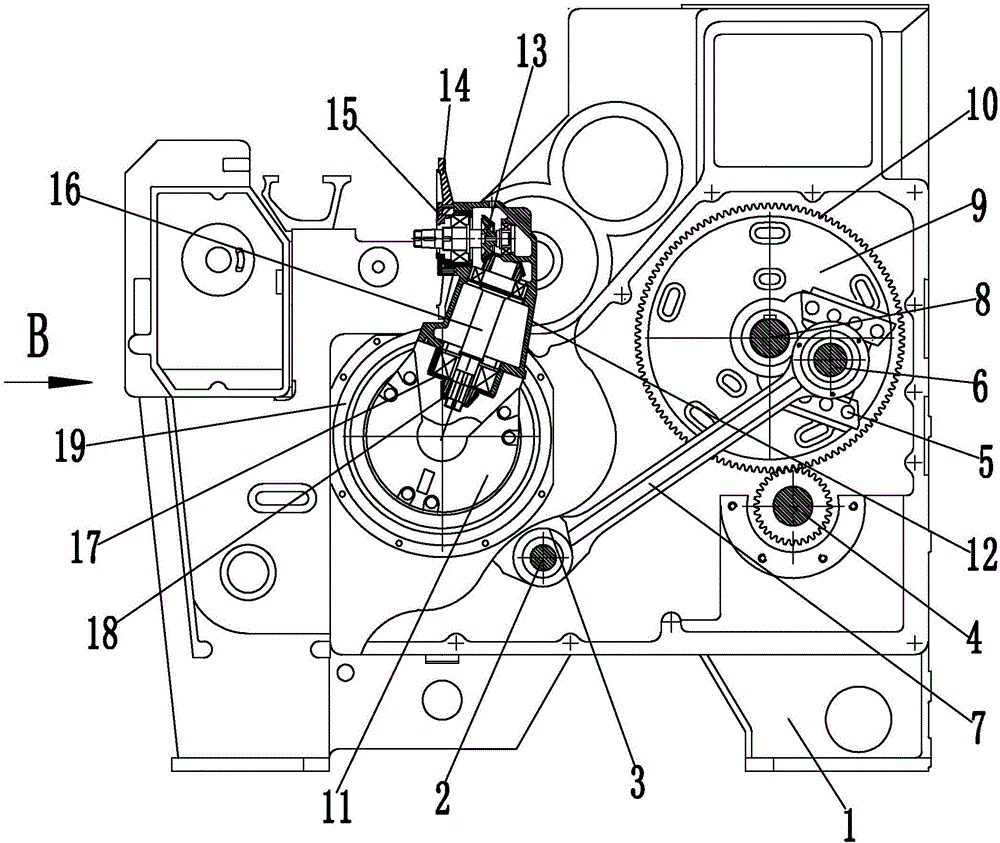

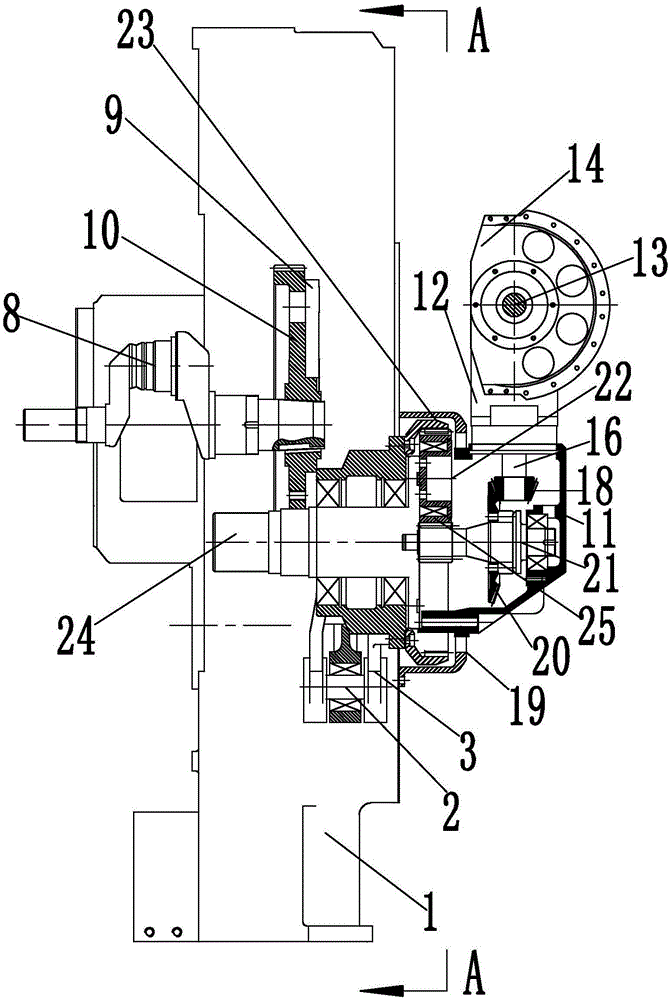

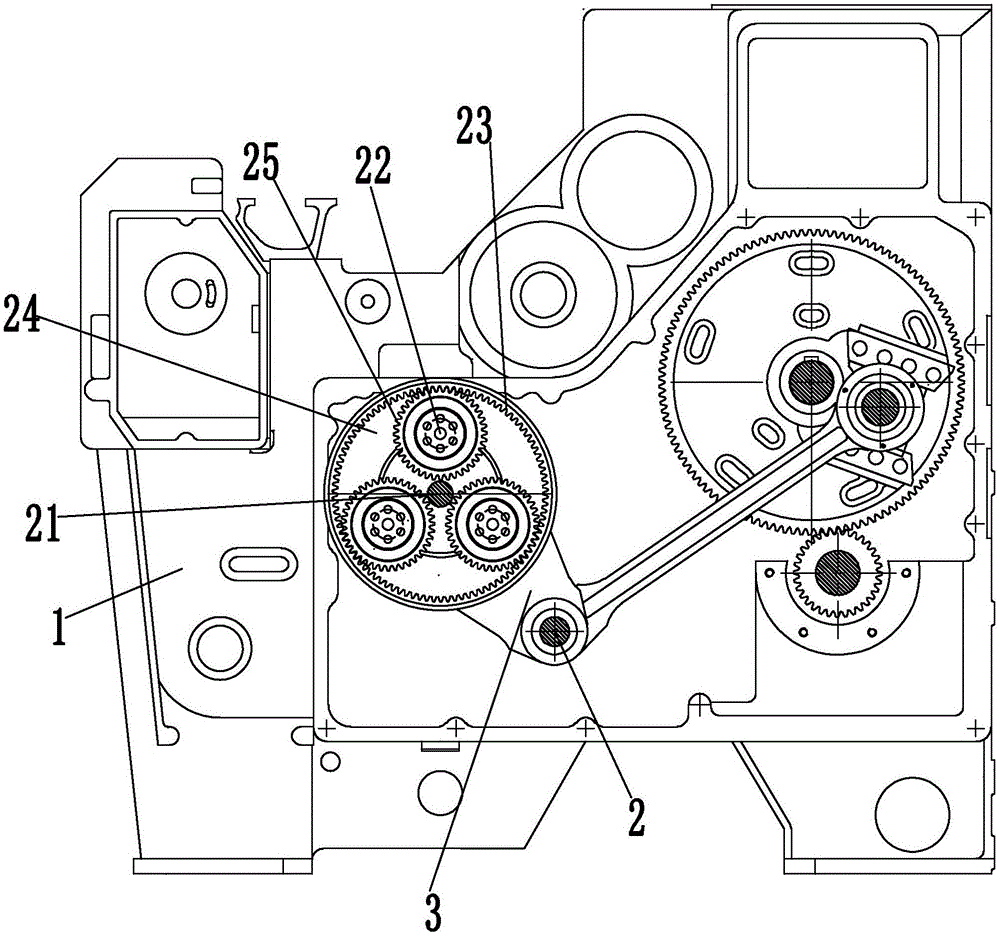

[0027] Such as Figure 1-3 As shown, the right weft insertion device of the high-speed rapier towel loom of the present invention includes a set of three-link mechanism, a set of planetary gear mechanism and two pairs of spiral bevel gear transmission mechanisms. The three-link mechanism swings, drives the planetary gear mechanism to rotate back and forth, and drives two pairs of spiral bevel gears to rotate back and forth through the transmission sword gear shaft, thereby realizing weft insertion.

[0028] The three-link mechanism in the present invention comprises right wallboard 1, right transmission gear shaft 4, eccentric pin pressing plate 5, eccentric pin 6, crankshaft 8, right transmission large gear 10, eccentric disc 9, right connecting rod 7, right connecting rod Lever pin 2, right swing arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com