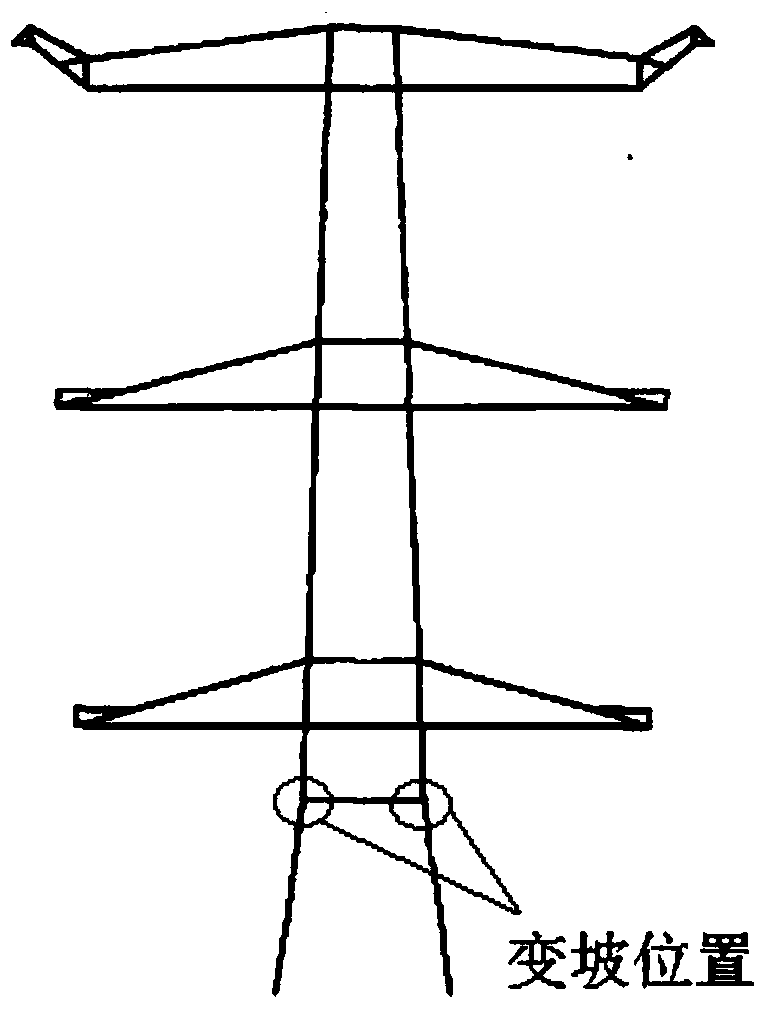

A design method for the slope-changing node of the steel pipe tower of the transmission line

A transmission line steel pipe and design method technology, applied to towers, building types, buildings, etc., can solve problems such as lack of continuity and standardization, low work efficiency, uneven design accuracy, etc., to overcome continuity and standardization , high work efficiency and high design precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The invention of this example provides a design method for variable slope joints of steel pipe towers of transmission lines, which comprehensively considers the influence of factors such as the number of bolts, the diameter of the upper and lower steel pipes of the variable slope joints, the wall thickness, the height and thickness of stiffeners, and the traditional design. Compared with the method, it is more convenient and efficient in engineering application.

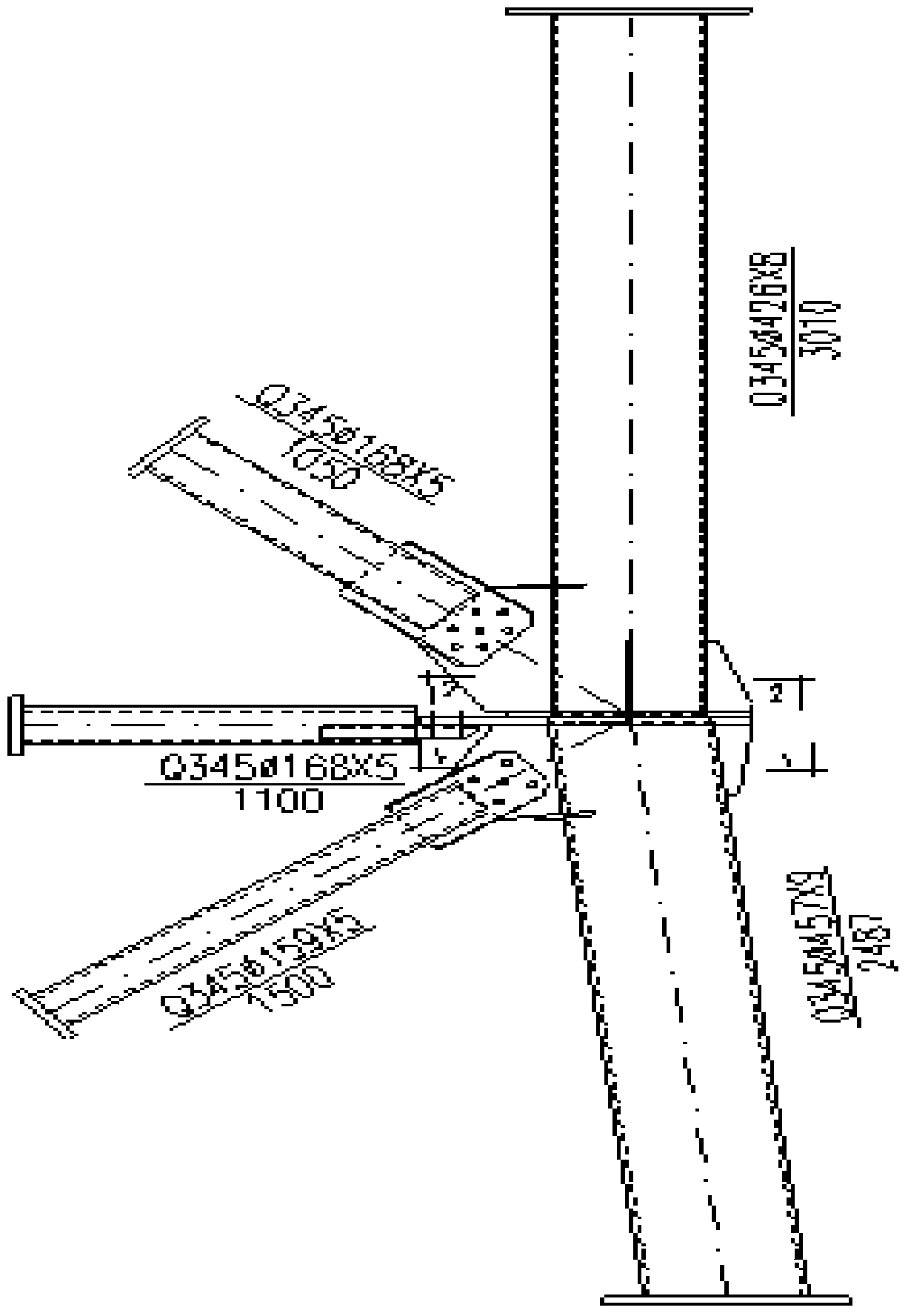

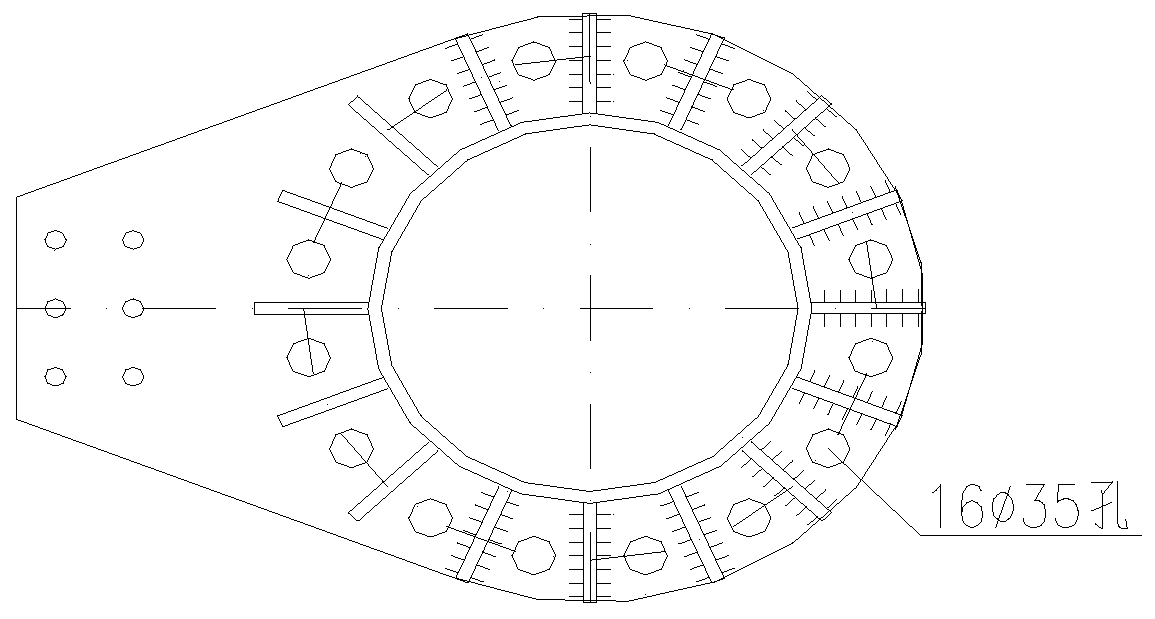

[0060] In order to achieve the above-mentioned purpose, the present invention constructs a multi-tower numerical model and a physical test model, and the layout and structure of the test device are damaged after reaching the ultimate bearing capacity. The method of theoretical calculation and experiment is used to calculate and analyze the stress state of the steel pipe main material at the variable slope node, such as figure 1 As shown, the configuration relationship between the initial main material pipe diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com