Shaft cast-plugging device and mounting method thereof

A technology of wellbore and barrel, applied in the field of wellbore plugging device and its installation, can solve the problems of safety risk and complicated operation, and achieve the effects of low operating cost, short well occupancy time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

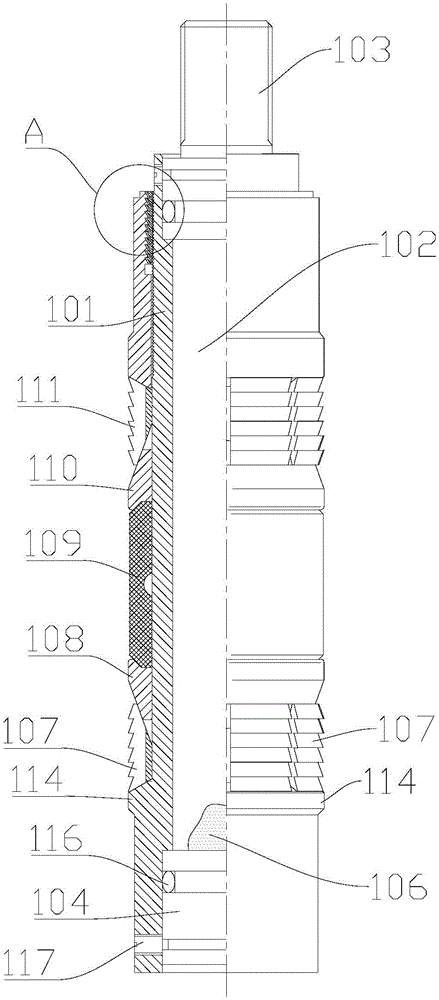

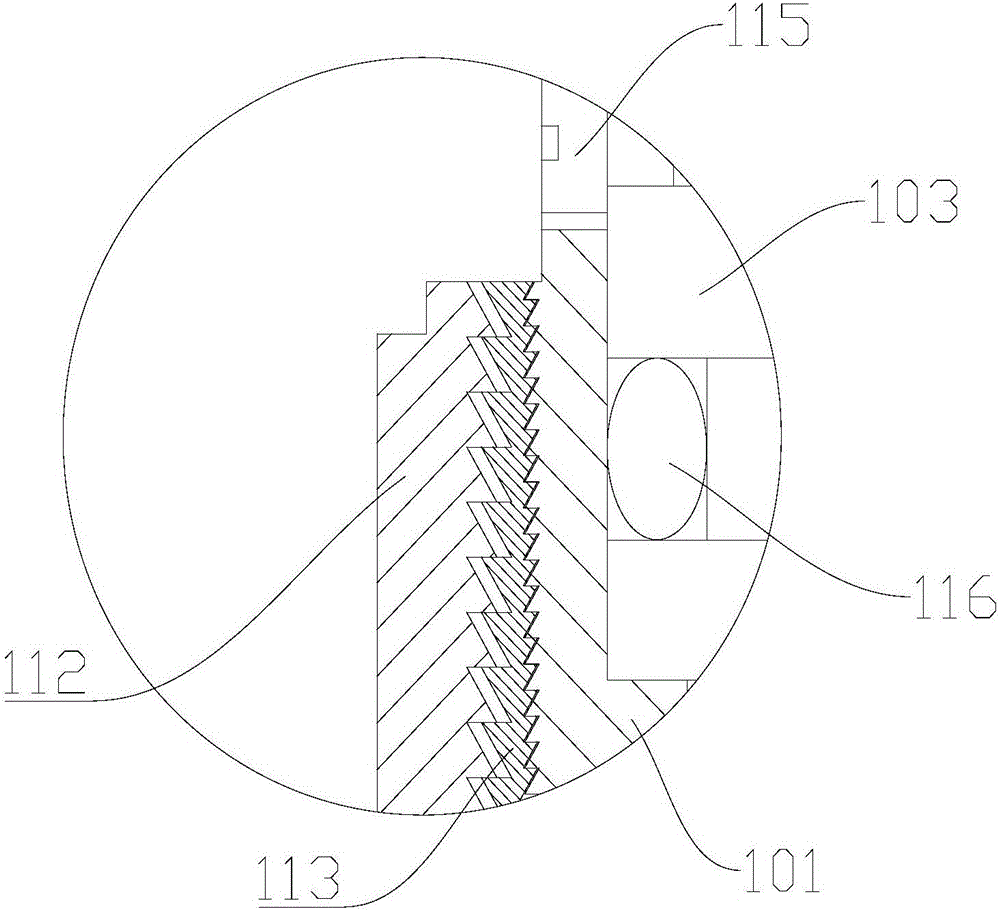

[0035] See figure 1 with figure 2 As shown, the first embodiment of the present invention provides a wellbore plugging device, including a plugging barrel 101. The plugging barrel 101 has a hollow cavity 102; the plugging barrel 101 also has corresponding head and tail ends. Specifically, the head end and the tail end of the plugging cylinder 101 are located in the axial direction of the hollow cylinder cavity 102; the head end is equipped with a drop connector 103 for connecting with the setting tool, and the tail end is equipped with a seal The plug 104, and the sealing plug 104 is located in the hollow cylinder cavity 102, the sealing plug 104 is made of degradable material; the outer surface of the plugging cylinder 101 is provided with a plugging mechanism for fixing the plugging cylinder 101 in the oil well , About to set the plugging cylinder 101 in the casing 105 of the oil well.

[0036] When in use, it is convenient to set the plugging barrel 101 in the casing 105 of t...

Embodiment 2

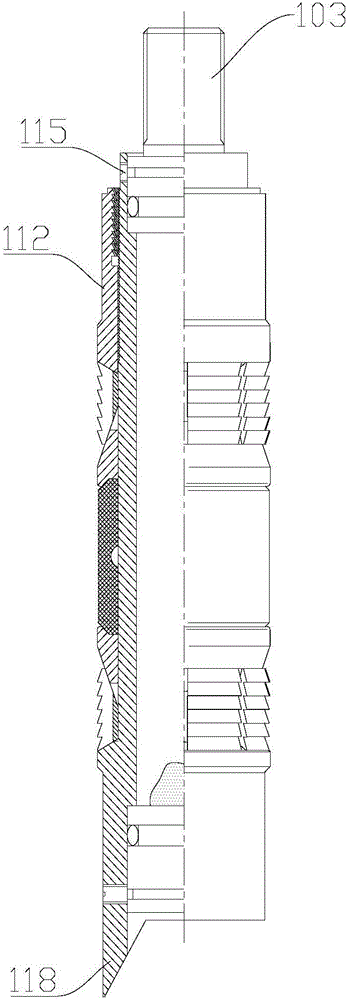

[0048] See image 3 As shown, the wellbore plugging device in the second embodiment is an improvement on the basis of the first embodiment. The technical content disclosed in the first embodiment is not described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in this embodiment.

[0049] The second embodiment of the present invention provides a wellbore plugging device. The end of the plugging barrel 101 has a stopper 118 for stopping the rotation of the plugging barrel 101, that is, when the wellbore plugging device After being set in the casing 105 of the oil well, the stopper 118 provided at the end of the wellbore plugging device can prevent the plugging barrel 101 from rotating; in addition, when the degradation function of the sealing plug 104 fails, the tool can be used to The second shear nail 117 is cut, so that when the sealing plug 104 is separated from the plug-in barrel 101, it can also serve to block the downward m...

Embodiment 3

[0051] See Figure 4 to Figure 7 As shown, the third embodiment of the present invention provides a method for installing the wellbore plugging device 100, where the wellbore plugging device 100 is the wellbore plugging device 100 in the first or second embodiment, and includes the following steps:

[0052] Step S100: Install the wellbore plugging device 100 on the setting tool. Specifically, the setting tool is a cable setting tool 119. The wellbore plugging device 100 and the cable setting tool 119 are connected, and the two are placed in the blowout preventer 121.

[0053] Step S200: Put the installed wellbore plugging device 100 and the setting tool into the casing 105 in the oil well, and lowering the wellbore plugging device 100 and the setting tool to a predetermined position in the oil well. Specifically, the blowout preventer 121 is lifted with a crane 124, and the blowout preventer 121 is connected to the wellhead of the oil well; the wellhead control valve is opened, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com