An eight-cone gear less tooth difference reducer

A technology of bevel gears and bevel gears is applied in the field of large transmission ratio reducers, which can solve the problems of poor heat dissipation, large starting torque and short service life, and achieve the effect of overcoming high temperature and high pressure resistance and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

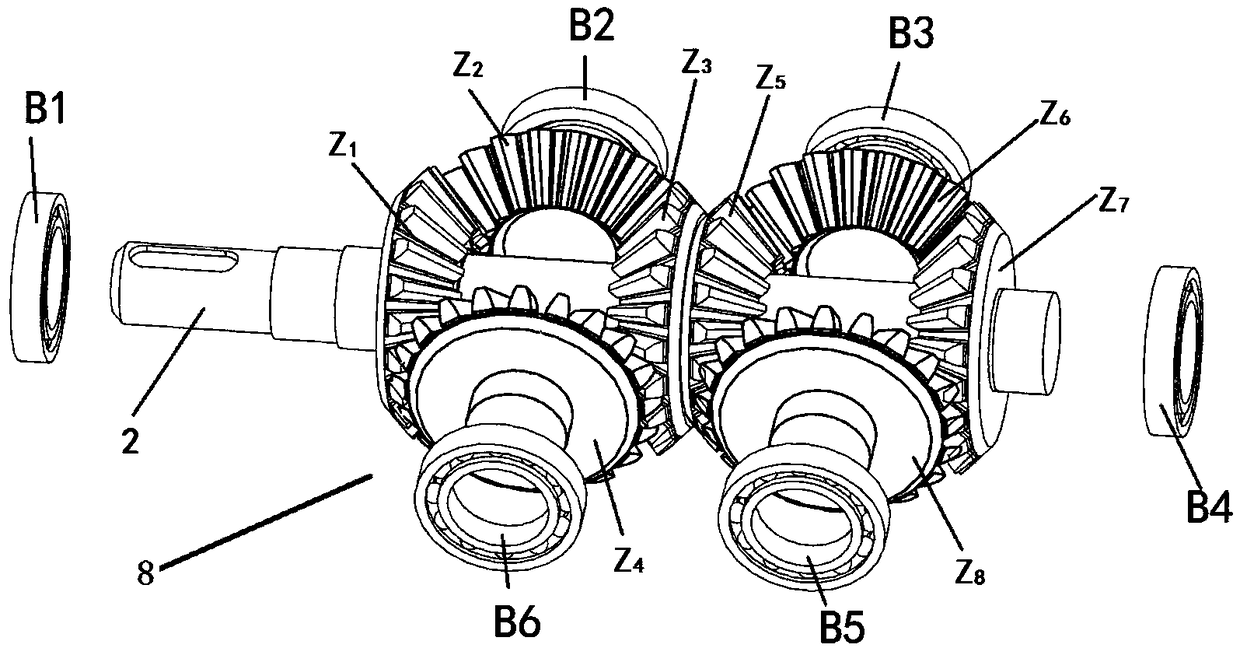

[0017] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

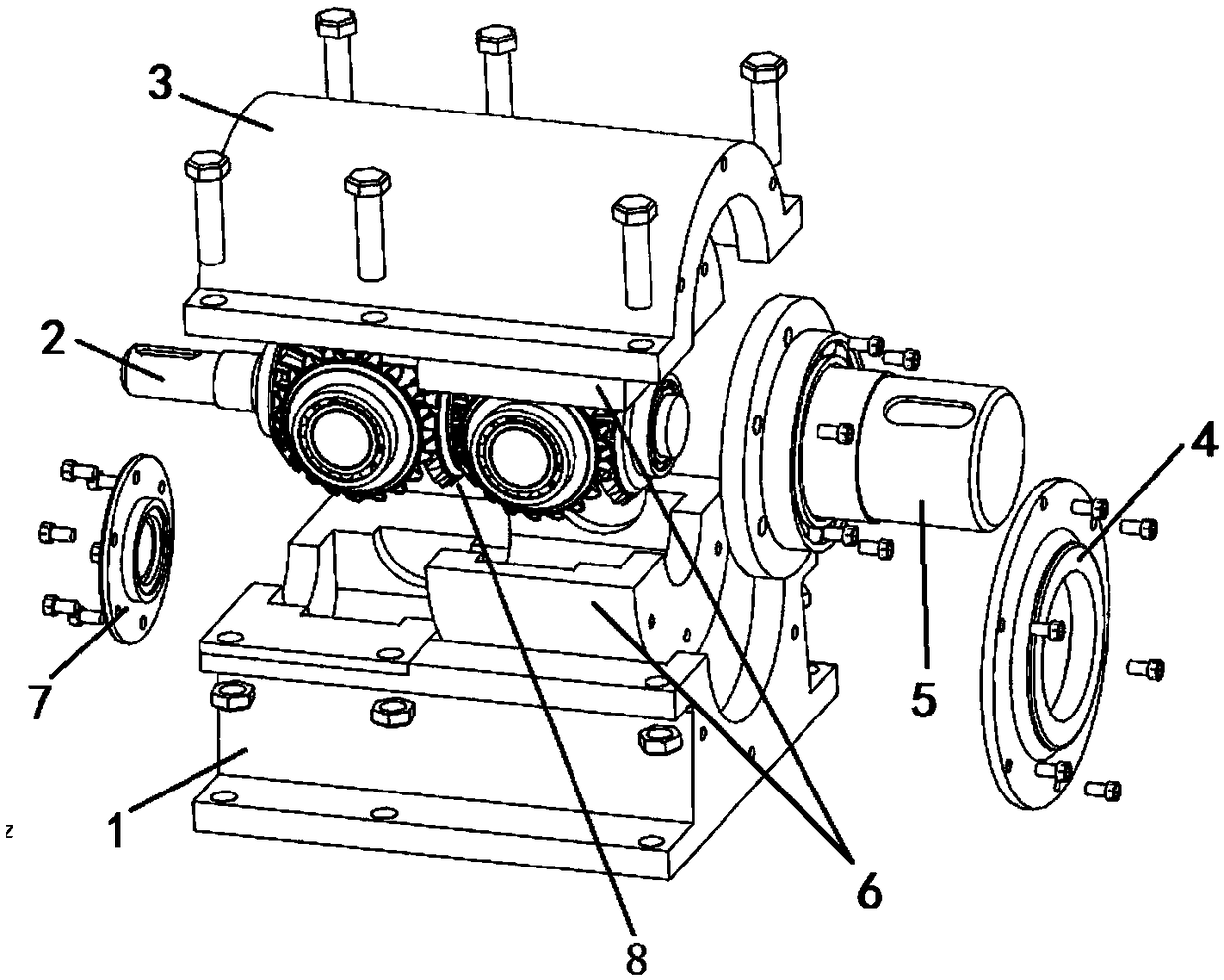

[0018] refer to figure 1 , an eight-bevel gear reducer with few teeth differences, including a base 1, the base 1 and the upper cover 3 are connected together by bolts, and the side of the base 1 is fixed with a bearing end cover 7 by screws to play the role of sealing and supporting the bearing;

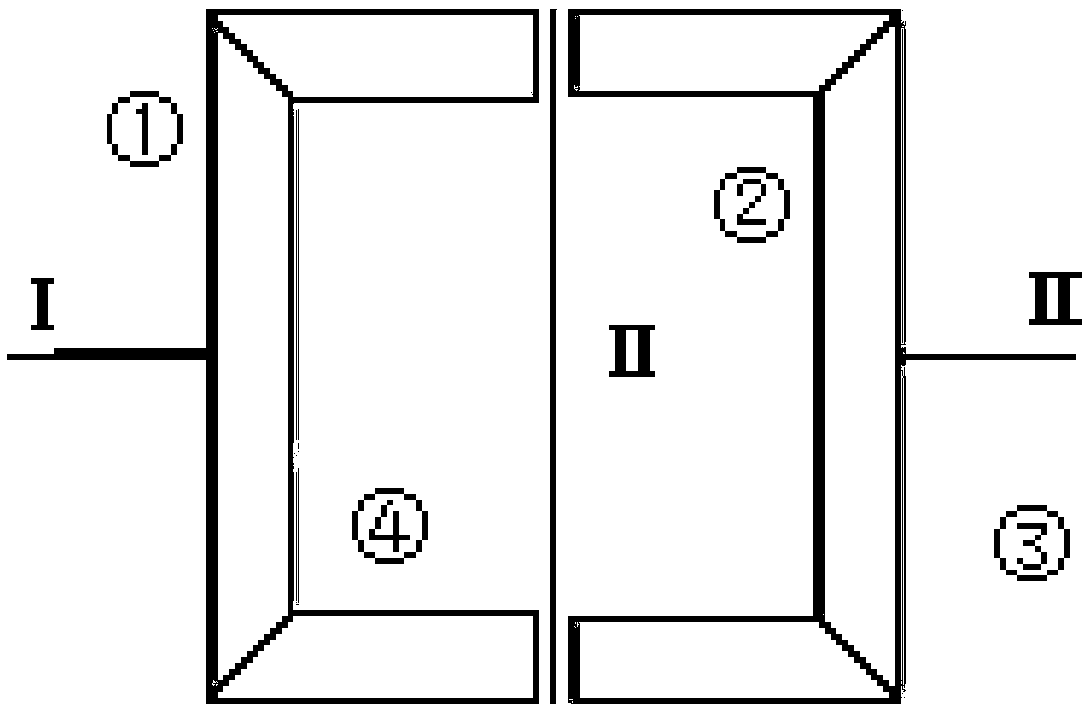

[0019] One end of the input shaft 2 is installed on the base 1 through a bearing, and the other end is connected with the rotor 6 through a bearing, so that the input shaft 2 can rotate around its axis, and the rotor 6 is installed on the base 1, and its outer cylindrical surface is connected with the base 1, The upper cover 3 constitutes a sliding pair. In order to ensure strength and reduce wear, the rotor 6 is made of steel, and a bearing bush is installed on the base 1 at the same time.

[0020] The output shaft 5 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com