Shock absorber for gearbox and shock absorbing protecting method

A shock absorber and gearbox technology, which is applied in the direction of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve problems such as rapid damage, deviation between distance and theoretical size, and affect the life of elastic bodies, so as to achieve rigidity Increases smoothness, eliminates additional constraints, and prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

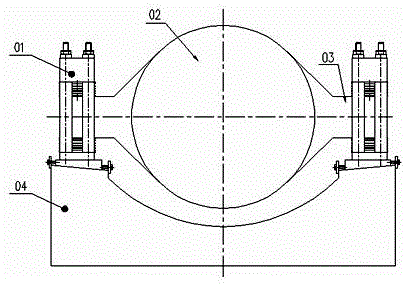

[0038] Such as figure 1 As shown, the gearbox shock absorber 01 is installed on both sides of the gearbox 02, the gearbox torque arm 03 passes through the middle space of the gearbox shock absorber 01, and the gearbox shock absorber 01 is fastened to the frame by bolts 04 on.

[0039] Such as figure 1 , figure 2 with image 3 As shown, the gearbox damper 01 includes a beam 1 , an elastic body 2 , a support tube 3 , a bottom plate 4 , a wedge-shaped backing plate 5 , a washer 6 , an adjusting bolt 7 and a jacking screw 8 . The two elastic bodies 2 of the gearbox shock absorber 01 are respectively placed between the beam 1 and the gearbox torsion arm 03, and between the bottom plate 4 and the gearbox torsion arm 03, and a certain amount of pre-compression is realized by bolts. The wedge-shaped backing plate 5 is installed between the bottom plate 4 and the frame 04. The frame 04 is processed into a slope with a certain angle and closely matched with the wedge-shaped backing...

Embodiment 2

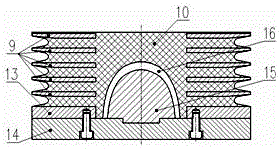

[0045] Such as Figure 8 As shown, the second embodiment is basically the same as the first embodiment, and one or more trumpet-shaped spacing structures with variable cross-sections are also distributed in the middle region of the elastic layer 10, but the spacing structures are blind holes that do not penetrate the elastic layer.

Embodiment 3

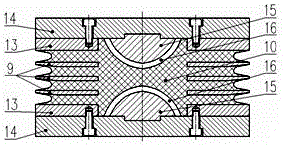

[0047] Such as Figure 9 As shown, the elastomer 2 includes a separator 9 and an elastic layer 10, and the separator 9 and the elastic layer 10 are bonded together through high-temperature vulcanization. Annular grooves 11 are distributed, and the upper and lower grooves 11 may or may not communicate with each other. The elastic block 12 in the middle of the elastic layer 10 is located in the middle of the annular groove 11, and the transverse direction of the annular groove 11 The cross-sectional area gradually increases from the middle of the elastic body 2 to the upper and lower surfaces, and the inner side of the longitudinal section of the groove is linear, and the outer side is arc-shaped. As the load borne by the elastic body 2 increases, the inner side of the elastic layer 10 and the outer side of the middle elastic block 12 gradually contact, and the same effect as that of the first and second embodiments can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com