Solder joint type detection method and apparatus based on image identification

A solder joint type and image recognition technology, applied in the field of automatic optical inspection, can solve the problems of troublesome plate making, low accuracy, poor stability, etc., and achieve the effect of simple and fast recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

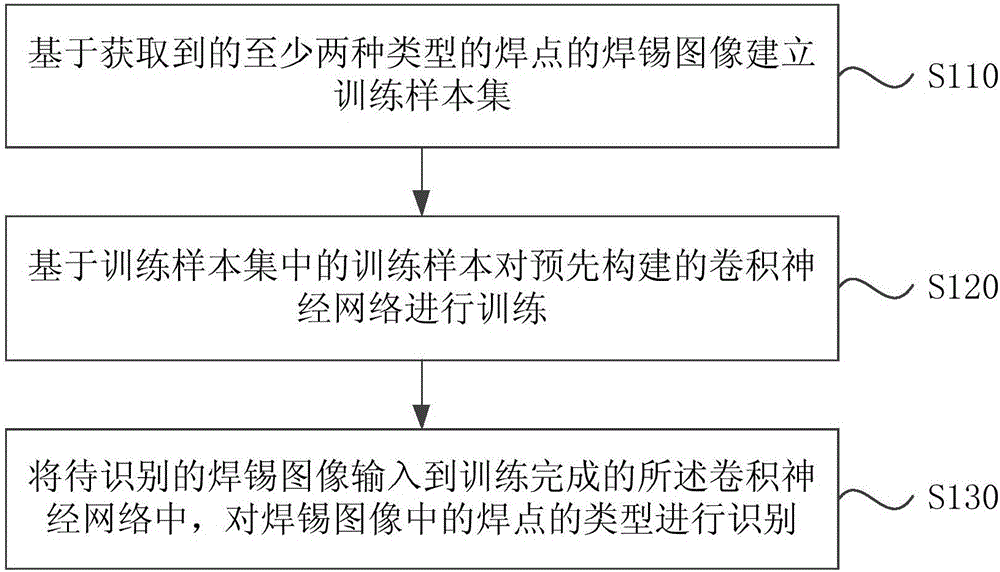

[0027] Figure 1A It is a flow chart of a solder joint type detection method based on image recognition provided by Embodiment 1 of the present invention. This embodiment is applicable to the detection of solder defects, and the method can be executed by a solder joint type detection device based on image recognition , including the following steps:

[0028] S110. Establish a training sample set based on the obtained solder images of at least two types of solder joints.

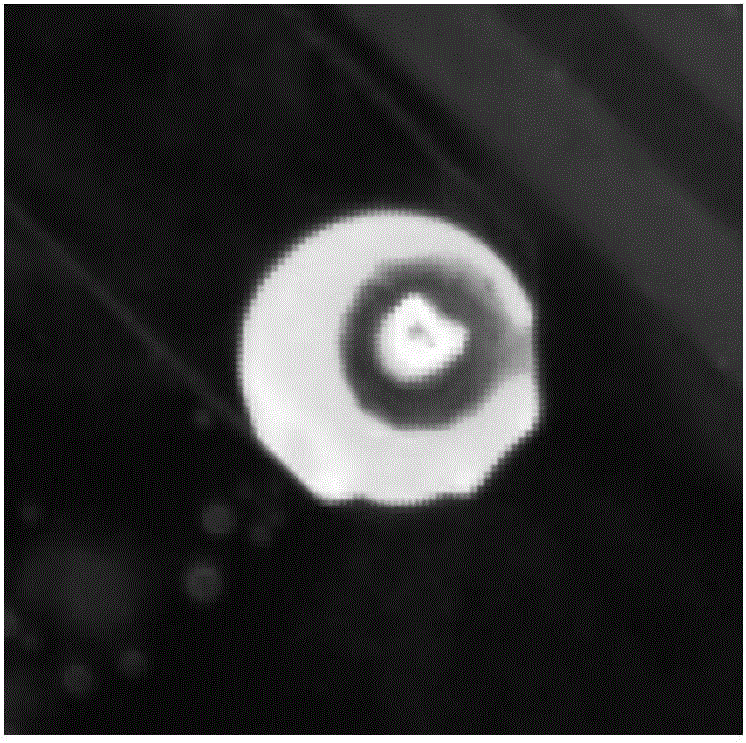

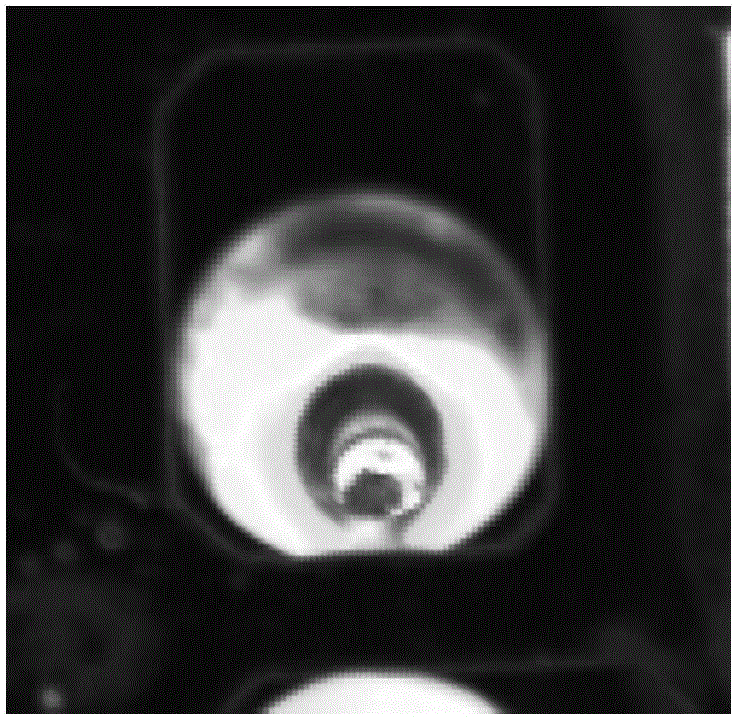

[0029] Wherein, at least two types of solder joints can include two types of solder joints, for example, the solder joints can be divided into two types: normal and abnormal; of course, more than two types of solder joints can also be included, such as Figures 1B-1E As shown, the types of solder joints can be more finely divided, such as normal ( Figure 1B ), Shaoxi ( Figure 1C ), Lianxi ( Figure 1D ) and / or multi-tin ( Figure 1E ) and other types. It can be understood that the normal solder joint t...

Embodiment 2

[0040] Figure 2A It is a flowchart of an image recognition-based solder joint type detection method provided by Embodiment 2 of the present invention. Such as Figure 2AAs shown, in this embodiment, on the basis of the above-mentioned embodiments, it is preferable to further optimize the training sample set based on the obtained solder images of at least two types of solder joints to obtain at least two types of solder joints Data expansion is performed on the original solder image; a training sample set is established based on the original solder image and the solder image after data expansion.

[0041] On this basis, it is optional that before training the pre-built convolutional neural network based on the training samples in the training sample set, it also includes: constructing a convolutional neural network comprising a parallel first subnetwork and a second subnetwork , wherein the number of layers included in the first subnetwork is greater than the number of layer...

Embodiment 3

[0068] image 3 Shown is a structural block diagram of an image recognition-based solder joint type detection device provided in Embodiment 3 of the present invention. The device can be implemented by means of hardware and / or software, and generally can be independently configured in a user terminal or server The method of this embodiment is implemented. Such as image 3 As shown, the image recognition-based solder joint type detection device specifically includes: a training sample set establishment module 310 , a convolutional neural network training module 320 and a solder joint type identification module 330 .

[0069] Wherein, the training sample set building module 310 is used to set up a training sample set based on the obtained solder images of at least two types of solder joints; the convolutional neural network training module 320 is used to pre-construct the training sample pairs based on the training sample set The convolutional neural network is trained; the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com