Action mechanism of residual current operated circuit breaker

A technology of residual current and action mechanism, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of affecting the tripping sensitivity, slow tripping speed, small tripping force, etc., and achieve smooth and smooth accelerated tripping process and accelerated rotation. Speed, action sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

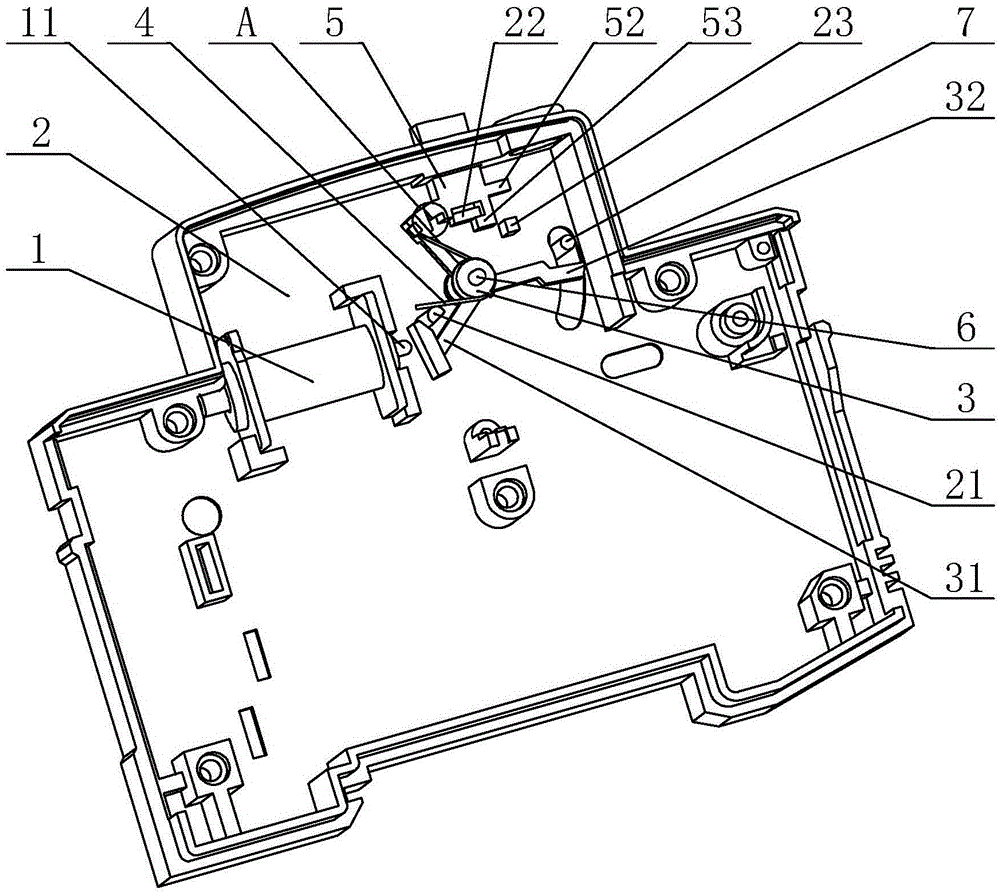

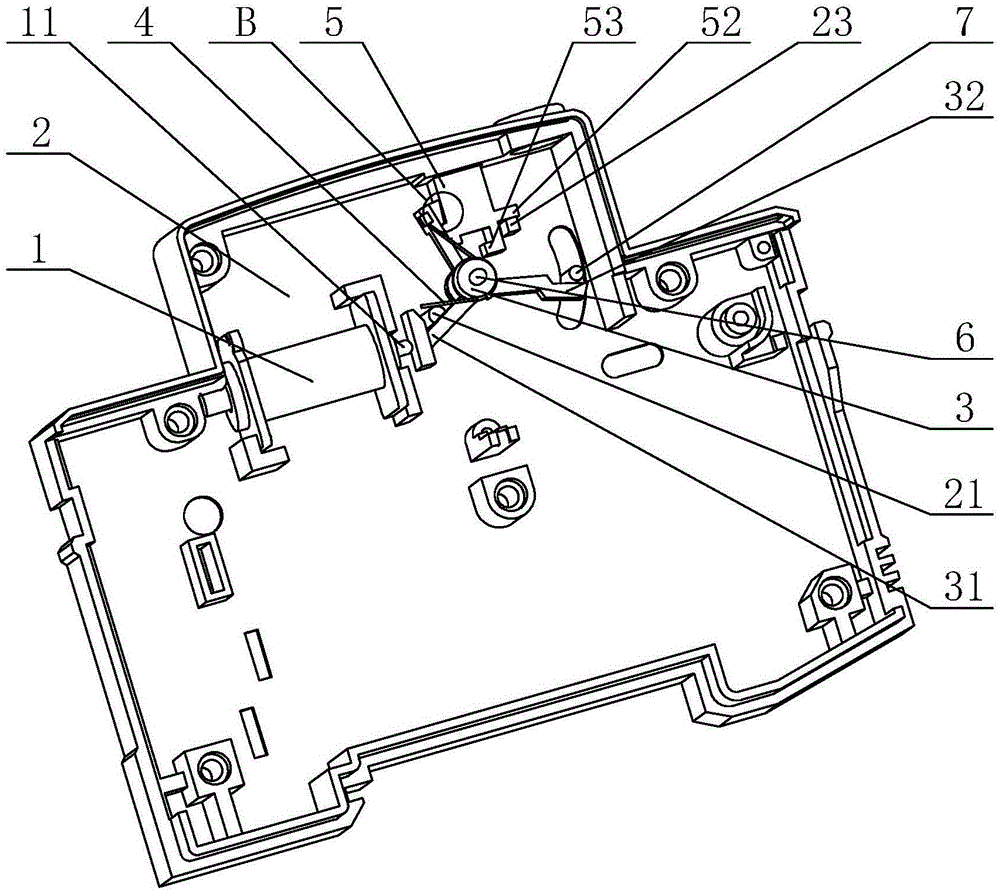

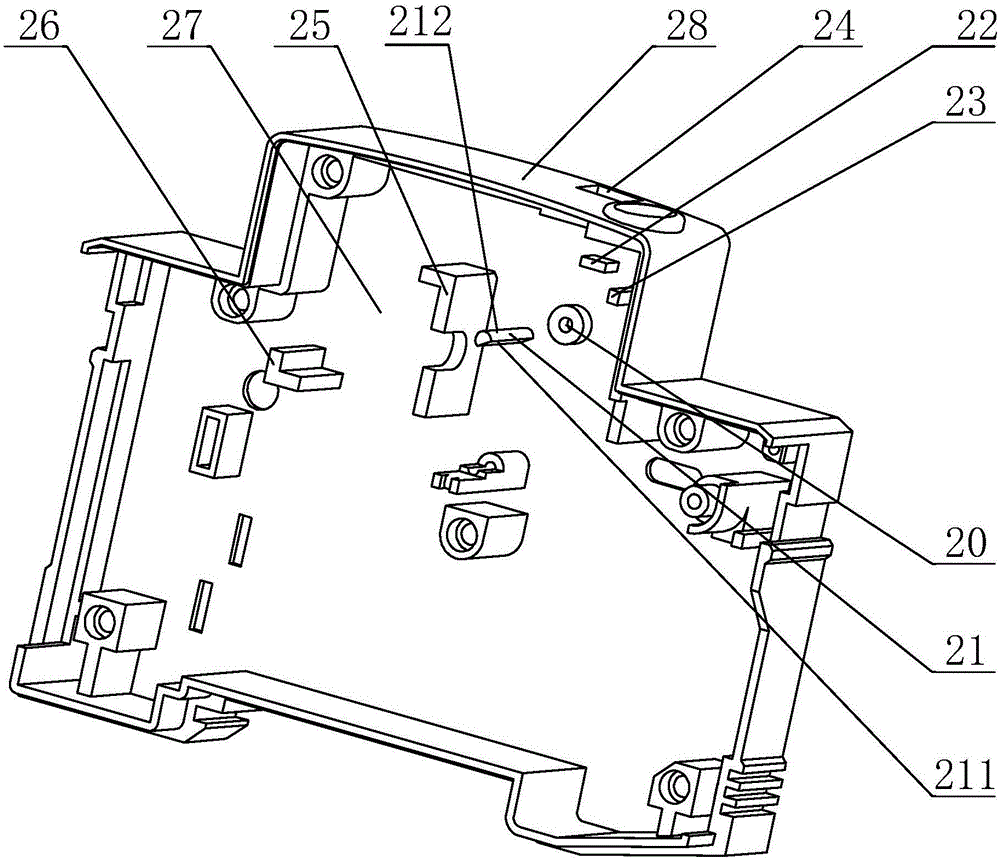

[0024] The following is attached Figures 1 to 7 The given examples further illustrate the specific implementation of the operating mechanism of the residual current operated circuit breaker of the present invention.

[0025] see figure 1 or figure 2 , the operating mechanism of the residual current operated circuit breaker of the present invention includes a tripping coil 1 fixed on the base 2 of the circuit breaker, a lever 3 pivotally installed on the base 2, and an indicator mounted on the base 2 in a linearly movable manner. Part 5, the return spring 4 that drives the lever 3 to rotate in the reset direction, and the energy storage spring (not shown) that drives the indicator 5 to move outward along the direction F in a straight line. combine Figure 3-7 In the illustrated embodiment, the lever 3 of the operating mechanism of the residual current operated circuit breaker of the present invention includes a shaft 30 that can pivot around the pivot 6 and a first arm 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com