Lead frame feeding device

A lead frame and frame technology, which is applied to the field of lead frame feeding devices, can solve the problems of uneven feeding spacing, easy wear of rails, and easy damage to products, and achieves the effects of not easy products and uniform feeding spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

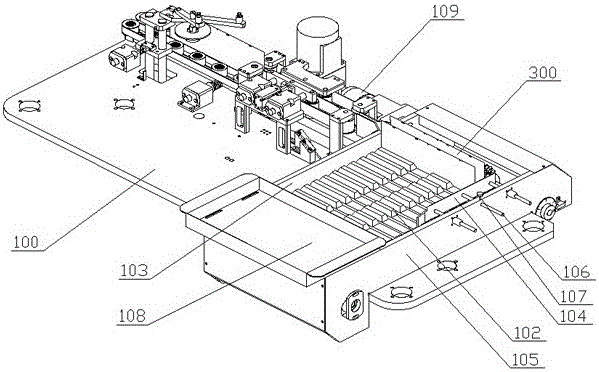

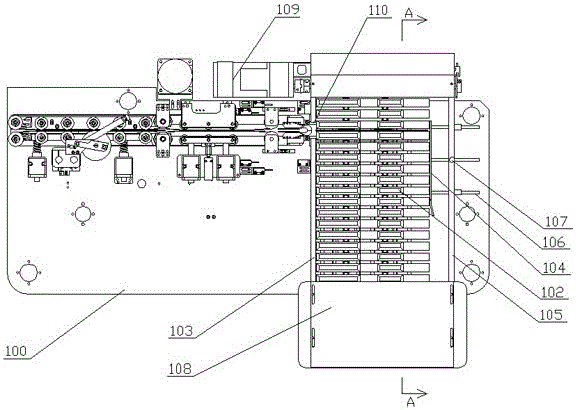

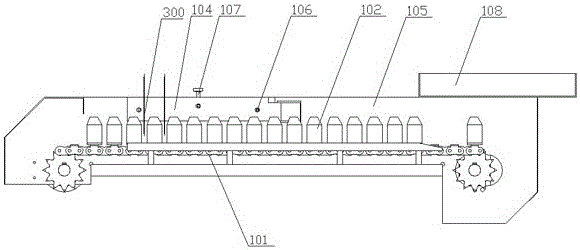

[0032] see Figure 1-Figure 10 , the present invention relates to a lead frame feeding device, which is arranged at the feeding end of the process tank of the steel strip vertical high-speed electroplating line, and the lead frame feeding device includes a lead frame feeding device arranged on the feeding device frame 100 Components and steel belt feeding components, the height of the feeding device frame 100 is adjusted by the lifting cylinder, the lead frame feeding component is arranged longitudinally, and the steel belt feeding component is arranged horizontally on the left side of the rear end of the lead frame feeding component the discharge end. The lead frame 300 is first sent to the steel strip feeding assembly through the lead frame feeding assembly, and then sent to the steel strip 400 of the vertical high-speed electroplating line for steel strip.

[0033] The lead frame feeding assembly includes a vertically arranged feeding conveyor chain 101, and a horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com