Organic light-emitting display panel, electronic equipment and manufacturing method thereof

一种发光显示、有机的技术,应用在电路、电气元件、电固体器件等方向,能够解决器件效率和寿命降低、效率降低、器件寿命降低等问题,达到提高发光效率和寿命、提高发光效率、提高产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

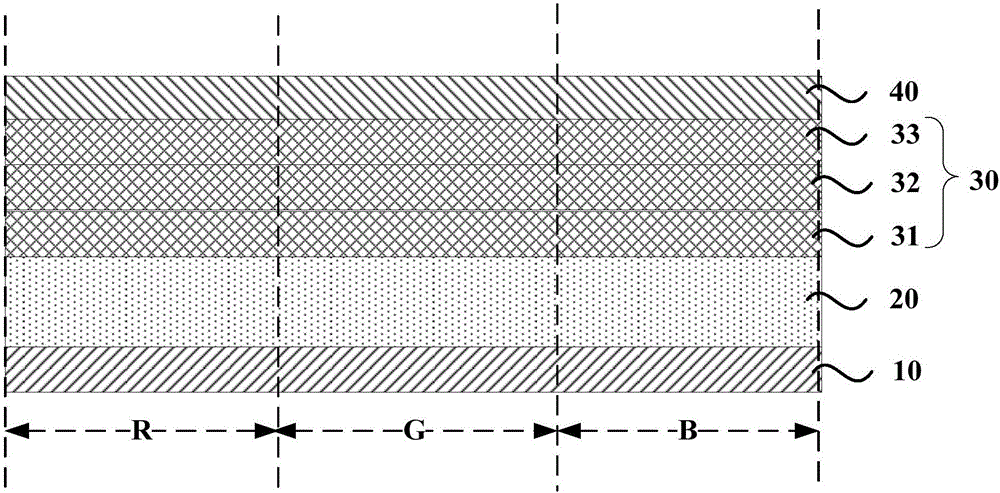

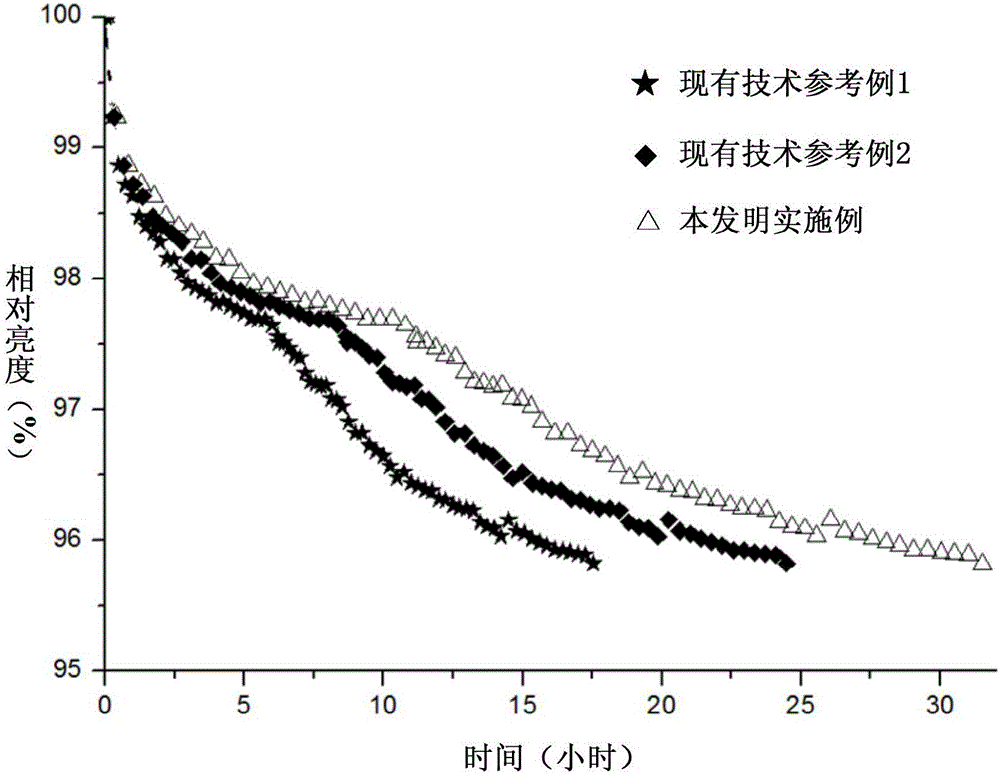

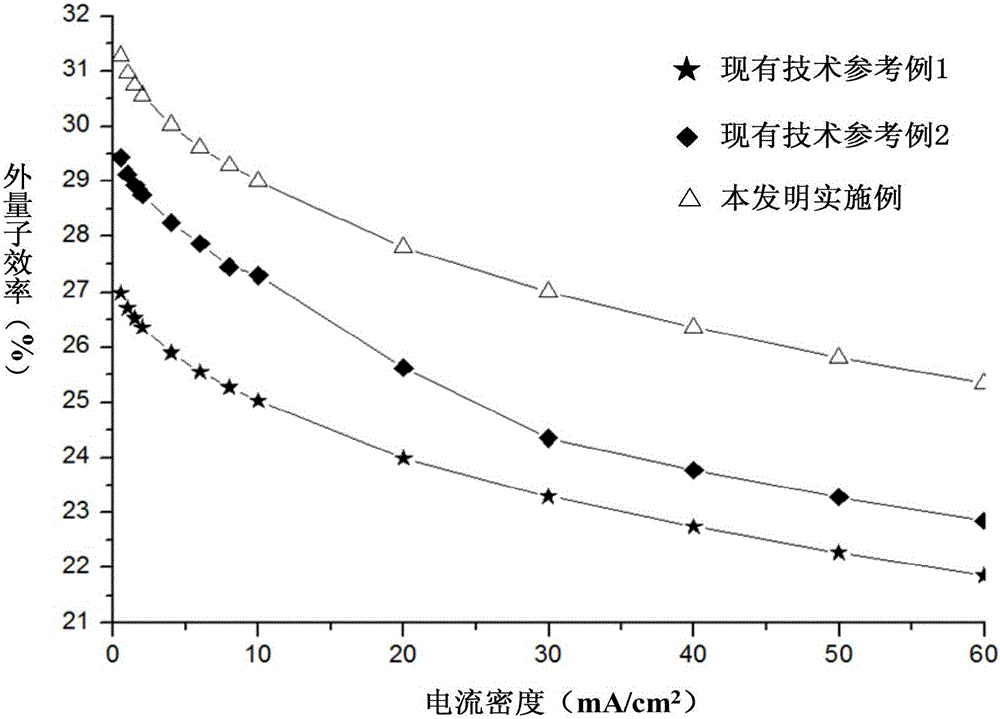

[0030] An embodiment of the present invention provides an organic light-emitting display panel, including at least a first electrode, a light-emitting layer, a first functional layer, and a second electrode that are stacked. Wherein, the first functional layer includes at least a first-type barrier layer, and the first-type barrier layer is disposed adjacent to the light-emitting layer. The first type barrier layer is doped with the first guest material; the ratio of the second type carrier mobility of the host ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com