Power distribution cabinet for workshop

A power distribution cabinet and power technology, which is applied in electrical components, circuit devices, emergency power supply arrangements, etc., can solve the problems of inconvenient operation and maintenance, lack of management, and difficulty in placing wire troughs, so as to facilitate timely observation and improve safety performance. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

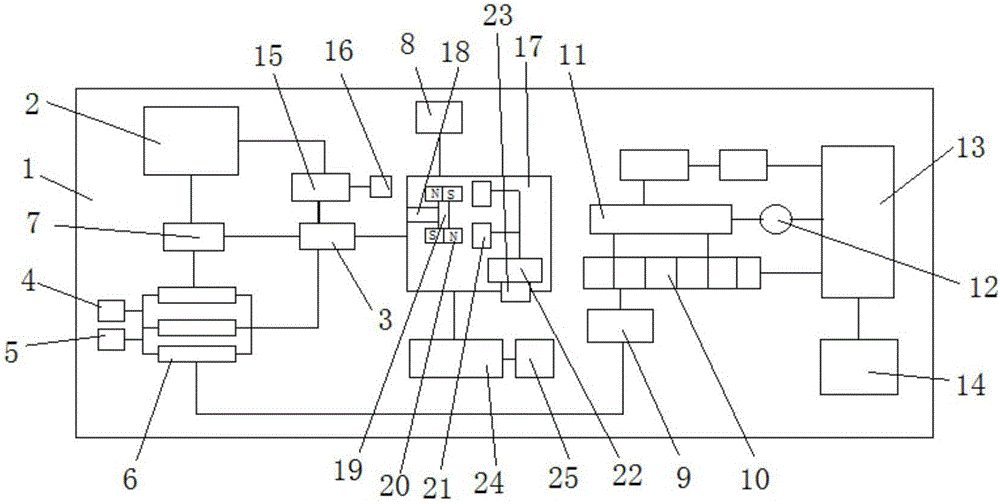

[0009] Referring to the accompanying drawings, a power distribution cabinet for a workshop includes a cabinet body 1, a mains power input terminal 2, the mains power input terminal 2 is connected to the mains, and an inverter switching module 3, and the mains power input module 2 is provided with a DC power input module 4, the DC power input module 4 and the AC power input module 5, the DC power input module 4 and the AC power input module 5 are respectively connected to a plurality of power UPS modules 6, the city Between the electric power source 2 and the power UPS module 6 are connected monitors 7 that can detect their respective performances. The monitors 7 are connected to the mains and inverter switching modules 3, and the three mains and inverter switching modules are connected to external The load 8, the power UPS module 6 and the mains power supply input terminal 2 are respectively connected to the charging module 9, and the charging module 9 is connected to the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com