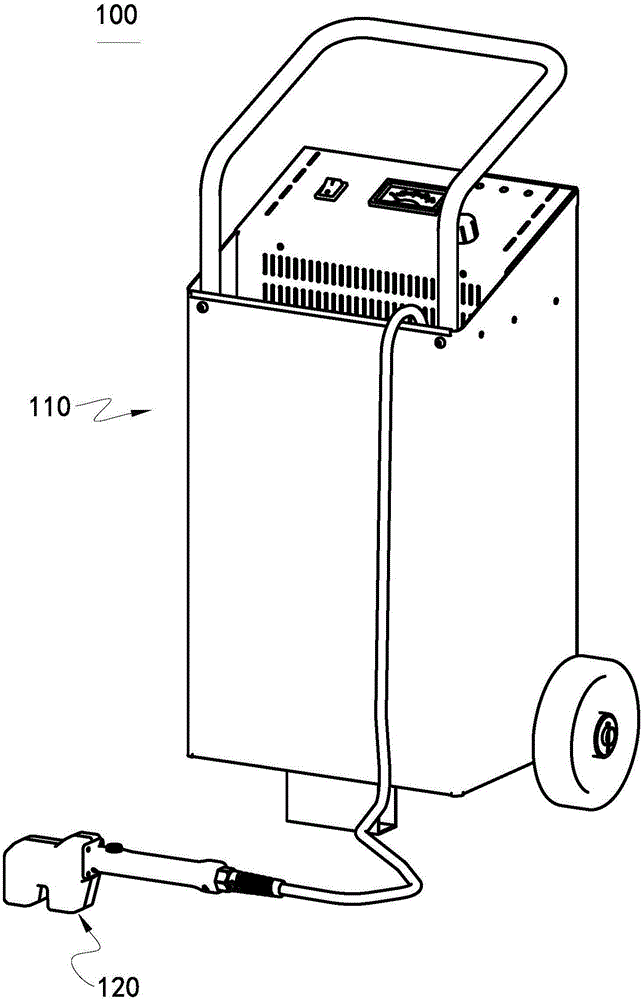

Inductive heating head and device for vehicle maintenance

A technology of automobile maintenance and heating devices, which is applied in the direction of induction heating devices, induction heating, induction heating control, etc., can solve problems such as sealing glue melting, achieve effective heat dissipation, avoid damage, and improve the effect of duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will be further described in detail in conjunction with the embodiments of the present invention and the accompanying drawings, especially to clarify and illustrate the unique structure and various possible implementation modes of the present invention, and the same parts of the embodiments as existing technologies such as CNCN203289678U are no longer To repeat, those skilled in the art can implement according to the structure and design common sense of existing products.

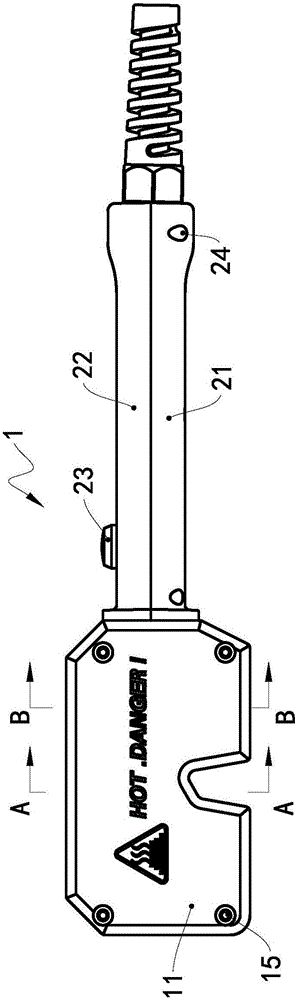

[0034] Example of Inductive Heating Head for Automobile Maintenance

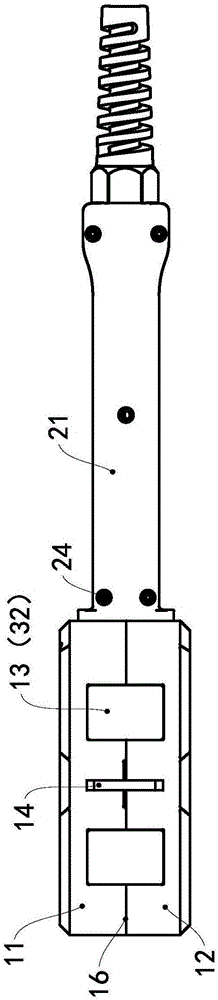

[0035] see figure 2 , image 3 , the induction heating head has two half-shells with the middle longitudinal section as the fastening surface, that is, the half-shell 11 and the half-shell 12 are in the image 3 The middle longitudinal section 16 is fastened, and the structure is basically symmetrical. In this example, the induction coil has a horseshoe-shaped magnetic core 32, and the two ends of the magnetic core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com