Ultrasonic breast inspection instrument

An ultrasonography instrument and examination instrument technology, applied in mammography, ultrasound/sonic wave/infrasonic wave diagnosis, ultrasound/sonic wave/infrasonic wave Permian technology, etc., can solve human discomfort, easy movement and deformation of the target body, and ultrasonic scanning The result does not add accuracy and other problems, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

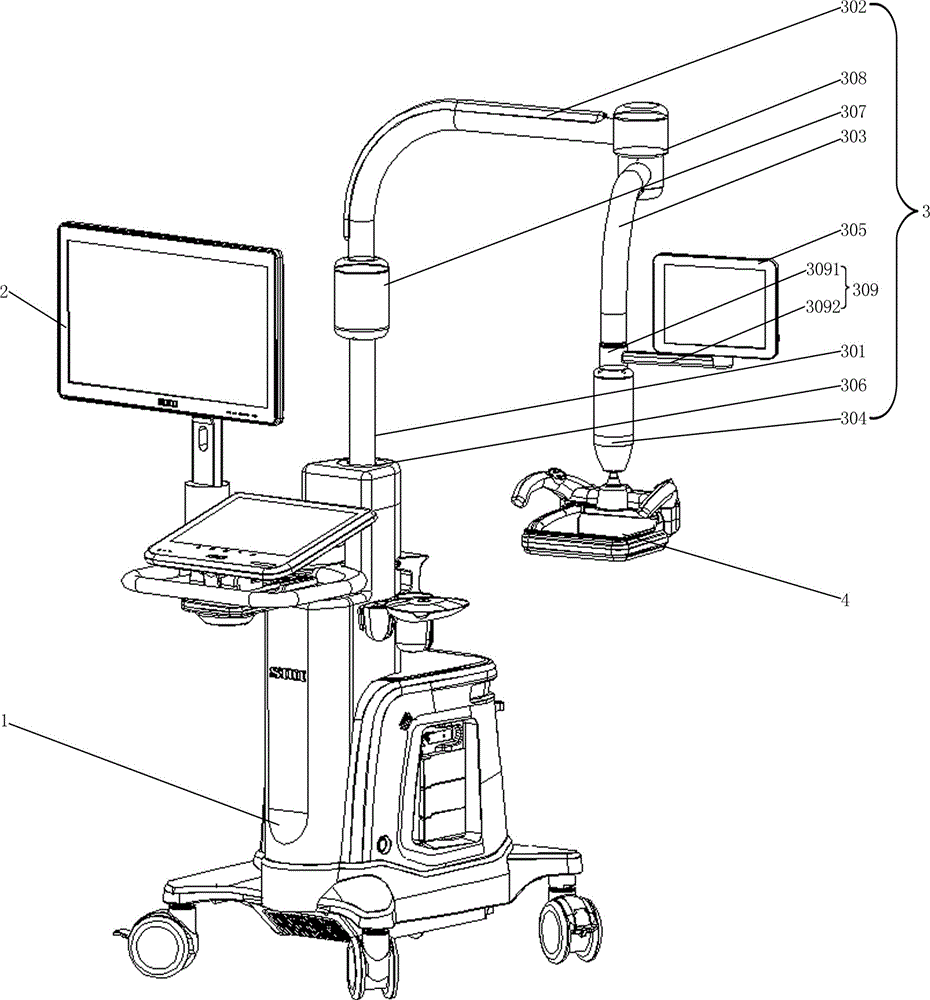

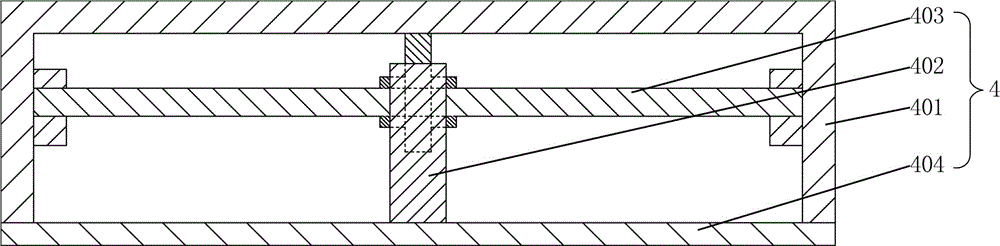

[0033] Such as figure 1 As shown, this mammary gland ultrasonography instrument includes an examination instrument main body 1, a first display 2, a support arm 3 and an ultrasonic scanning device 4, the first display 2 is installed on the examination instrument main body 1, and one end of the support arm 3 is installed on the On the inspection instrument main body 1, the ultrasonic scanning device 4 is installed on the other end of the support arm 3; as figure 2 As shown, the ultrasonic scanning device 4 includes a housing 401, an ultrasonic probe 402, and a probe moving device 403 capable of moving the ultrasonic probe 402. The bottom of the housing 401 is provided with a hard base plate 404; the ultrasonic probe 402 and the probe moving device 403 are all installed in the housing. In 401 , the lower end surface of the ultrasonic probe 402 is in contact with the upper surface of the hard base plate 404 and coupled through a coupling agent.

[0034] The above-mentioned prob...

Embodiment 2

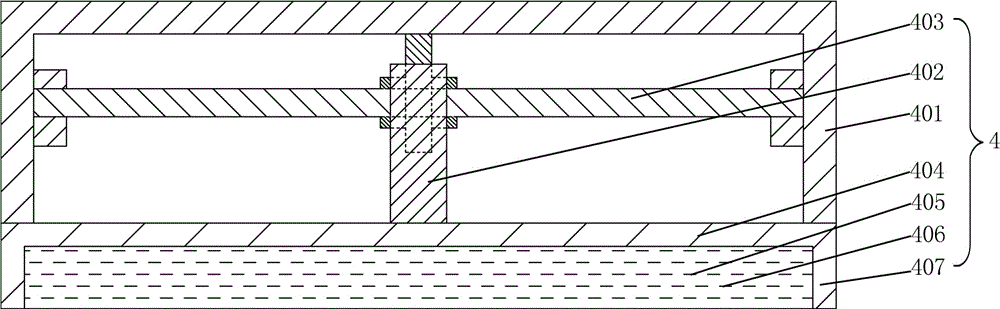

[0040] Such as image 3 As shown, on the basis of Embodiment 1, the ultrasonic scanning device 4 adds a coupling capsule 405, and the coupling capsule 405 is filled with a coupling agent 406; wherein, the edge of the hard base plate 404 extends downward to form a coupling cavity 407, and the coupling capsule 405 is installed in the coupling cavity 407 , and the upper side of the coupling bag 405 is in close contact with the lower surface of the hard bottom plate 404 .

Embodiment 3

[0042] Such as Figure 4 , Figure 5 As shown, in the case that other parts are the same as in Embodiment 1, the only difference is that: the cross section of the hard base plate 404 of the ultrasonic scanning device 4 is set to be arc-shaped; the probe moving device 403 includes a driving device ( Figure 5 not shown in), transverse guide rail 4031, transverse slider 4032, transverse encoder 4033, longitudinal guide rail 4034, longitudinal slider 4035, longitudinal encoder 4036, pressure sensor 4037 and spring 4038; the driving device and transverse guide rail 4031 are installed on In the inner cavity of the housing 401, the transverse slider 4032 is installed on the transverse guide rail 4031 and can move along the transverse guide rail 4031, the transverse encoder 4033 is arranged on the transverse slider 4032, and the power output end of the driving device is connected to the transverse slider 4032; The longitudinal guide rail 4034 is installed on the horizontal slider 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com