Reinforced bamboo sheet cover production method and reinforced bamboo sheet cover thereof

A production method and reinforcement technology, applied in the direction of wood heating, manufacturing tools, wood processing utensils, etc., can solve the problems of service life impact, shortened product service life, easy to grow insects, etc., to achieve good reinforcement, prolong service life, The effect of preventing mold and insects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0022] Specific embodiment one: a kind of manufacture method of reinforced type bamboo sheet lid is characterized in that finishing according to following steps:

[0023] (1) Pretreatment of bamboo chips: including anti-mildew and anti-moth treatment and drying treatment;

[0024] (2) The interface and shape of the bamboo slices are trimmed, and the bamboo slices are put into the reinforcement ring butt-jointed to form the original body of the lid;

[0025] (3) The original body of the lid is put into the shaping mold and baked to shape;

[0026] The anti-mildew and anti-moth treatment includes soaking the bamboo chips in the anti-mildew and anti-moth treatment liquid for 18-30 hours, keeping the temperature at 40-55° C., and then taking out the bamboo chips and draining the water.

[0027] The anti-mildew and anti-moth treatment solution is prepared from the following raw material components:

[0028] 7 parts of edible vinegar, 5 parts of alcohol, 5 parts of alum, 3 parts o...

specific Embodiment 2

[0033] Specific embodiment two: a kind of manufacture method of reinforcement type bamboo sheet lid is characterized in that finishing according to following steps:

[0034] (1) Pretreatment of bamboo chips: including anti-mildew and anti-moth treatment and drying treatment;

[0035] (2) The interface and shape of the bamboo slices are trimmed, and the bamboo slices are put into the reinforcement ring butt-jointed to form the original body of the lid;

[0036] (3) The original body of the lid is put into the shaping mold and baked to shape;

[0037] The anti-mildew and anti-moth treatment includes soaking the bamboo chips in the anti-mildew and anti-moth treatment solution for 30-48 hours, keeping the temperature at 40-55° C., and then taking out the bamboo chips and draining the water.

[0038] The anti-mildew and anti-moth treatment solution is prepared from the following raw material components:

[0039] 7 parts of edible vinegar, 5 parts of alcohol, 5 parts of alum, 3 pa...

specific Embodiment 3

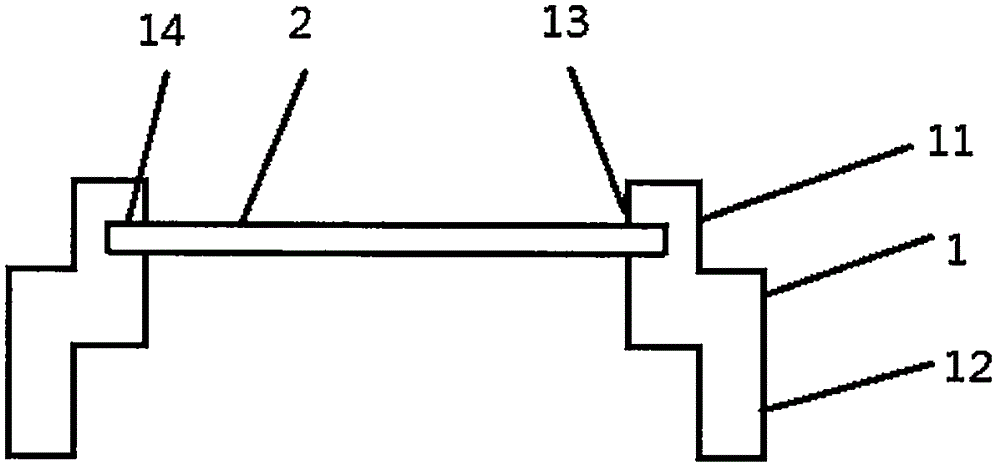

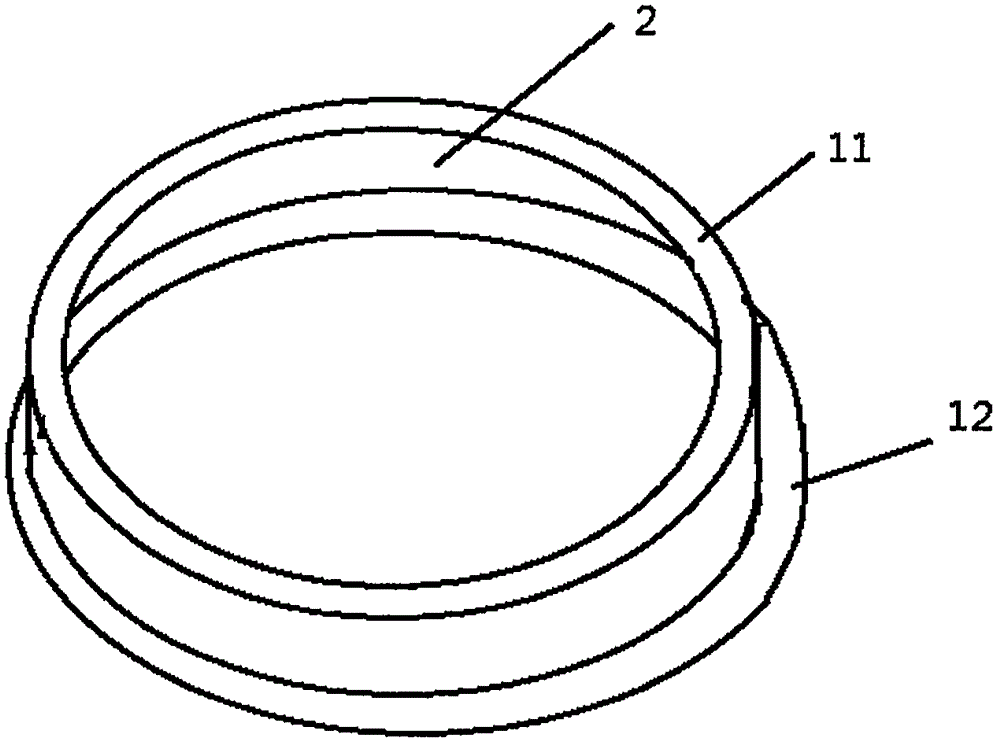

[0046] A reinforced bamboo cover includes a bamboo cover body 2 and a reinforcing ring 1 clamping the edge of the bamboo cover body. The reinforcing ring 1 includes an upper ring 11 and a lower ring 12, the upper ring 11 and the lower ring 12 are connected in a relative dislocation, and the inner surface 13 of the upper ring is provided with a card slot 14, and the card slot 14 can hold bamboo pieces lid edge.

[0047] The beneficial effects of this specific embodiment are: the reinforced bamboo sheet cover of the present invention has a stable structure, and the cover will not be scattered due to splitting of the spliced parts, and the cover will not be moldy or moth, and has a long service life; the bamboo sheet cover can be shaped made into different surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com