An integral compartment structure liquid propellant delivery device

A liquid propellant and delivery device technology, applied in aerospace vehicle propulsion system devices, transportation and packaging, fuel tanks of power devices, etc., can solve problems such as large mass and volume, restrictions, large system mass and space volume, etc., to achieve Realize the effect of gas-liquid isolation and prevent air entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

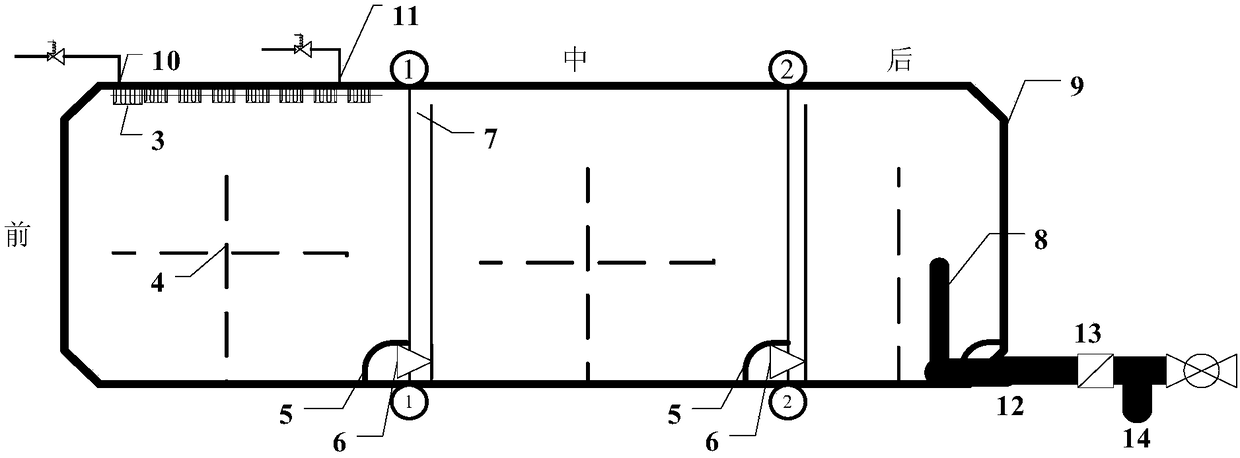

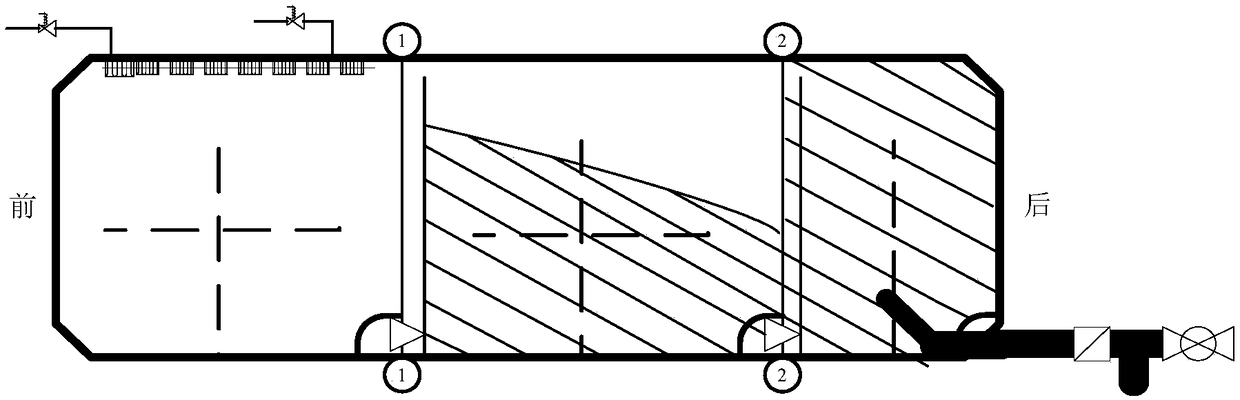

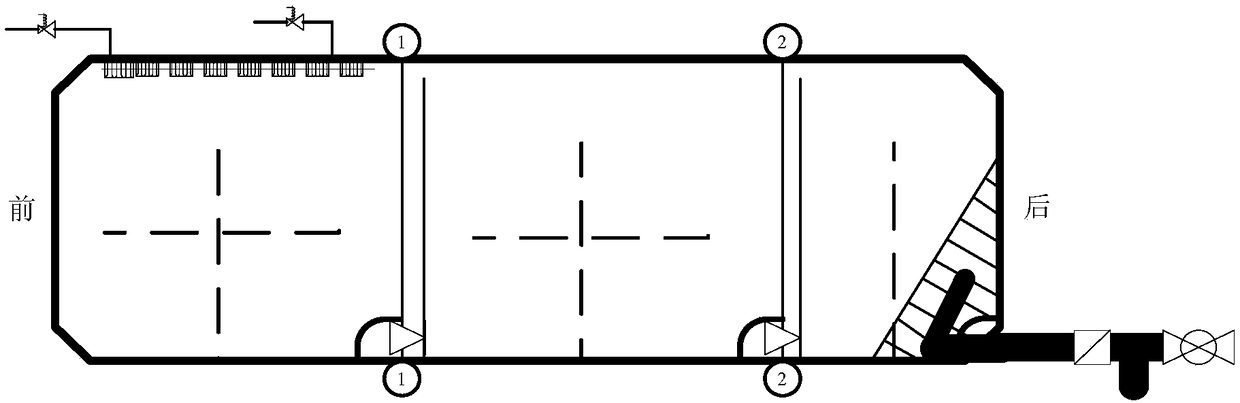

[0024] like figure 1 Shown is a schematic diagram of the overall structure of the liquid propellant delivery device in the empty oil state. It can be seen from the figure that a liquid propellant delivery device with an integral compartment structure includes a first partition 1, a second partition 2, and an energy-dissipating air guide groove 3. Anti-sway baffle 4, air bubble screen 5, baffle one-way valve 6, diversion channel 7, swing liquid collector 8, tank shell 9, pressurized air inlet 10, pressurized exhaust port 11 , Oil outlet pipeline 12; Wherein, storage tank shell 9 is the shell structure of liquid propellant conveying device; It is fixedly installed inside the storage tank shell 9; the energy dissipation air guide groove 3 is fixedly installed on the inner wall of the top of the storage tank shell 9; one end of the energy dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com