Air-out noise abatement system for soundproof room

A technology of silent room and muffler, which is applied in the direction of sound insulation, indoor acoustics, noise suppression, etc. It can solve the problems of high installation cost, small ventilation and small size of silent room, etc., and achieve low production cost, large noise reduction, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

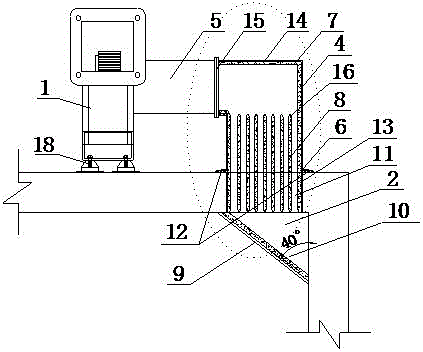

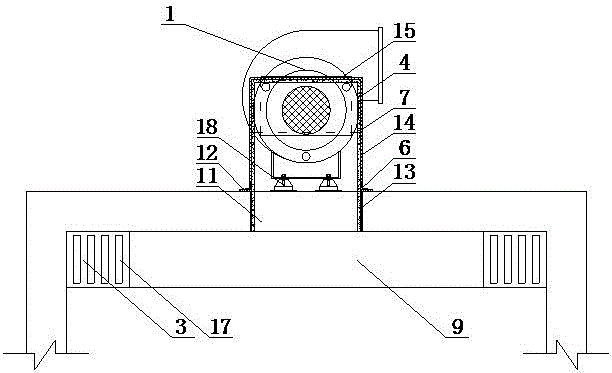

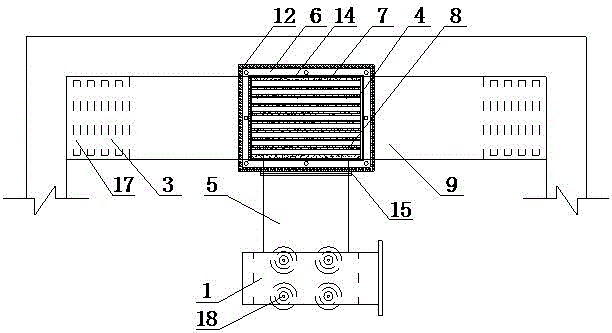

[0038] Such as figure 1 , 2 . As shown in 3, a kind of air outlet noise reduction system for a quiet room, including a centrifugal fan (1), an impedance composite muffler, a noise elimination channel (2), and a perforated sound-absorbing panel (3), the impedance composite muffler is composed of a muffler Housing (4), centrifugal fan interface (5) mounting part, mounting flange (6), internal sound-absorbing material (7) and high-density sound-absorbing inserts (8) with a thickness of 10mm and a spacing of 15-25mm, The impedance compound muffler is installed on the top side of the silent room; the muffler channel (2) is set inside the silent room, and consists of a sound insulation board (9) and a perforated sound absorption board (3). The surface forms an included angle of 40°, and the sound insulation board (9) is equipped with a low-density sound-absorbing board (10) and the top of one side in the quiet room to form a cross-sectional area of a right-angled triangle wind-ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap