Silencer pipe

一种消音、管道的技术,应用在声衰减领域,能够解决外壳沉重、难以制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

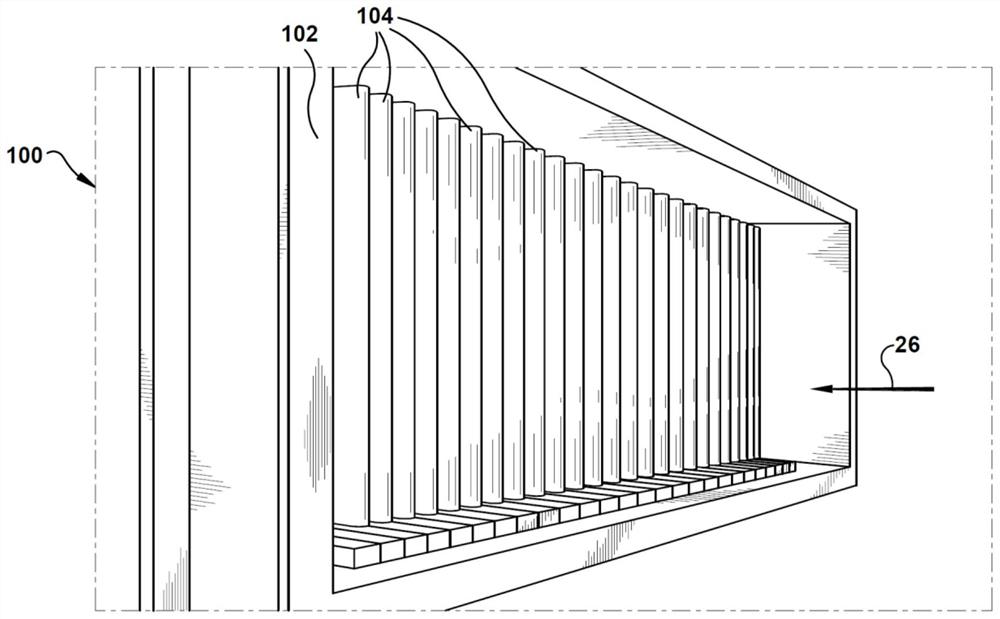

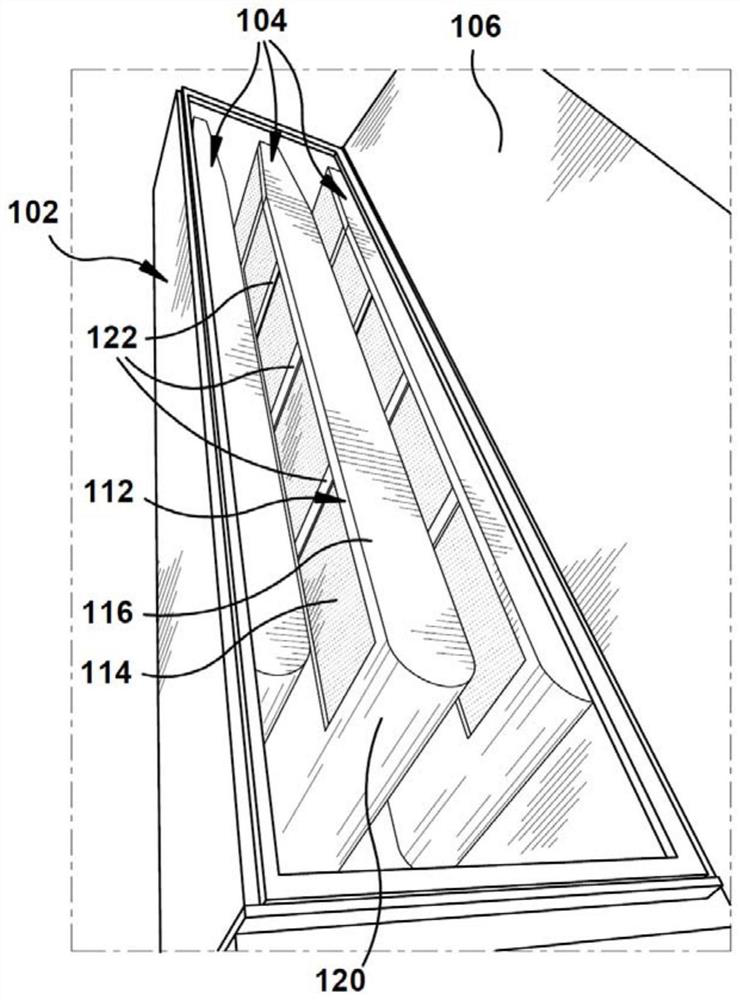

[0052] As described above, the present invention provides a sound dampening panel and sound dampening system comprising at least one plastic perforated side wall. In addition, the invention comprises acoustic panel sections or sections, (modular) acoustic panels and acoustic ducts which can slidably receive the acoustic panels.

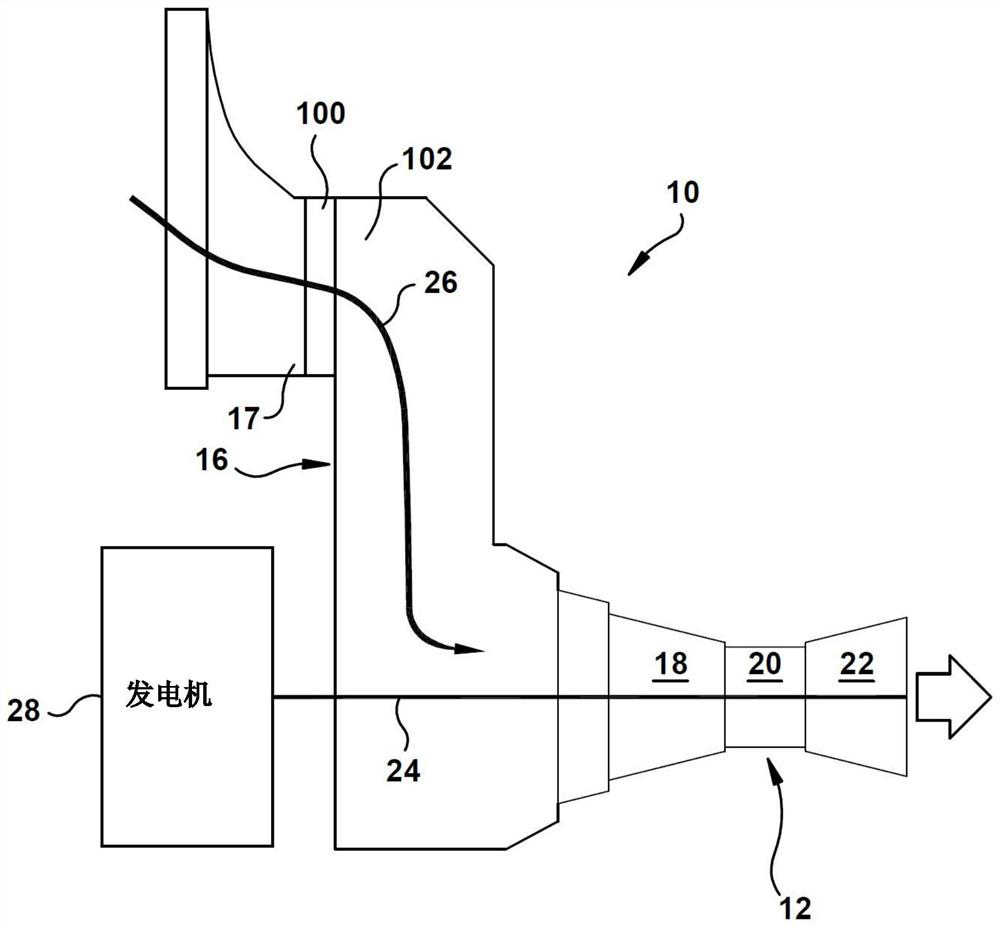

[0053] With reference to the accompanying drawings, figure 1 An exemplary industrial machine in the form of a turbine system 10 (eg, a single cycle gas turbine power generation system) in which a gas turbine system 12 may be included is depicted. Gas turbine system 12 may combust a liquid or gaseous fuel, such as natural gas and / or hydrogen-rich syngas, to generate hot combustion gases to drive gas turbine system 12 . Gas turbine system 12 includes an air intake section 16 , a compressor 18 , a combustor component 20 , and a turbine component 22 . Turbine member 22 is drivingly coupled to compressor 18 via shaft 24 . In operation, air (eg, ambient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com