Safety Wrapped Cam Handles

A technology of safety bag and cam, applied in the direction of mechanical equipment, coupling, etc., can solve the problem of Teflon property damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

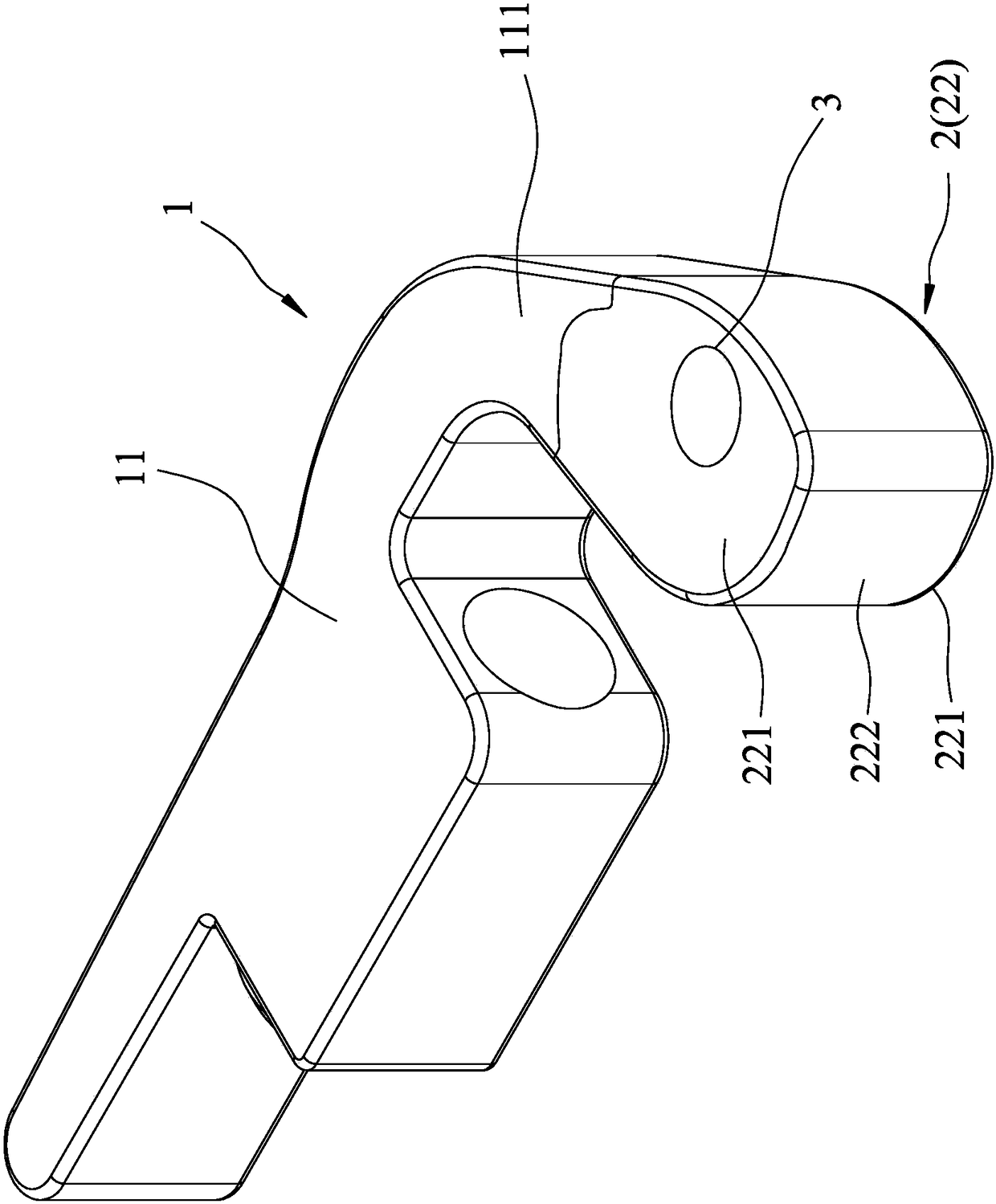

[0029] refer to figure 2 , A first embodiment of the safety-covered cam handle of the present invention includes a handle body 1 , a cover body 2 , and a shaft hole 3 .

[0030] refer to image 3 , the handle body 1 includes a locking seat 11 having a front end 111 , and a cam frame 12 formed on the front end 111 . The cam frame 12 has two opposite side surfaces 121, multiple groove surfaces 122 perpendicular to the side surfaces 121, a grasping structure 123 defined by the groove surfaces 122, and a peripheral surface 124 connected to the edge of the side surfaces 121. , and an inner shaft hole 125 passing through the side surface 121 . Wherein, each embedded groove surface 122 forms at least one embedded engaging portion 131 . It should be noted that the purpose of the engaging portion 131 is to engage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com