A leather processing method for making upper leather from inner leather

A processing method and leather technology, applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problem of insufficient material fineness of two-layer pigskin materials, low economic benefits of leather materials, and low gloss of leather materials Advanced issues, to achieve the effect of increasing added value, increasing product added value, and increasing double-color feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The leather processing method of making top leather from lining leather in this embodiment includes the following steps:

[0058] (1) Material selection: select lining materials;

[0059] (2) First spin-off: Put the selected lining into a drum for spin-off processing to destroy the dermal tissue fibers of the lining and make the leather soft;

[0060] (3) Paste particle film: paste a layer of particle film on the leather surface;

[0061] (4) Spray adhesive resin: spray adhesive resin material on the surface of the particle film to form an adhesive resin layer;

[0062] (5) Pasting metal film: Paste a metal film on the surface of the resin layer;

[0063] (6) The second spin-off: Put the metal film-laminated leather into a rotating drum for spin-soft processing, so that the grain surface of the leather is exposed;

[0064] (7) Spray color rubbing: spray color rubbing paint on the soft leather material for the second time;

[0065] (8) Polishing: Throw away the raised parts of the le...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is that the adhesive resin of this embodiment is composed of the following parts by weight of raw materials:

[0073] 50 parts of ethyl orthosilicate, 10 parts of aliphatic hydrocarbons, 10 parts of lower alcohols, 3 parts of titanate-silane coupling agent.

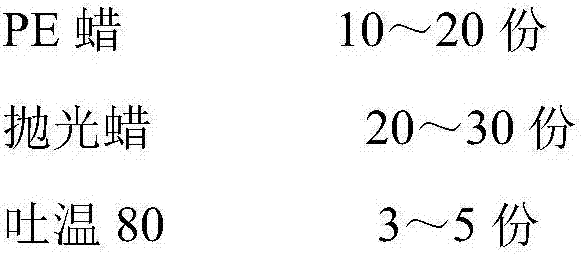

[0074] Among them, the rubbing paint is a mixture of wax agent and nitrocellulose in a mass ratio of 3.5:6.5. The wax agent is composed of the following parts by weight of raw materials:

[0075] PE wax 12 parts

[0076] Polishing wax 22 parts

[0077] Tween 80 4 parts

[0078] Six polyglycerol monostearate 11 parts

[0079] 9 parts of polyolamine

[0080] Sodium dodecylbenzene sulfonate 12 parts

[0081] 160 parts of deionized water.

[0082] Among them, the fixing resin is cetylpyridinium chloride.

[0083] The rest of the content of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0085] The difference between this embodiment and embodiment 1 is that the adhesive resin of this embodiment is composed of the following parts by weight of raw materials:

[0086] 52 parts of ethyl orthosilicate, 12 parts of aliphatic hydrocarbons, 12 parts of lower alcohols, 5 parts of titanate-silane coupling agent.

[0087] Among them, the rubbing paint is a mixture of wax agent and nitrocellulose in a mass ratio of 4:6. The wax agent is composed of the following parts by weight of raw materials:

[0088] PE wax 15 parts

[0089] Polishing wax 25 parts

[0090] Tween 80 3.5 parts

[0091] Six polyglycerol monostearate 10 parts

[0092] 9 parts of polyolamine

[0093] Sodium dodecylbenzene sulfonate 13 parts

[0094] 170 parts of deionized water.

[0095] Among them, the fixing resin is a mixture of a binary copolymer of cetylpyridinium chloride, acrylamide and acrylic acid in a mass ratio of 1:3.

[0096] The rest of the content of this embodiment is the same as that of Embodiment 1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com