Method of preparing composite material substrate by mixing glass and acrylic, and products thereof

A composite material and acrylic technology, which is applied in the field of the manufacturing method of glass and acrylic to make composite material substrate and its products, which can solve the problems of easy breakage, poor rigidity and insufficient hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

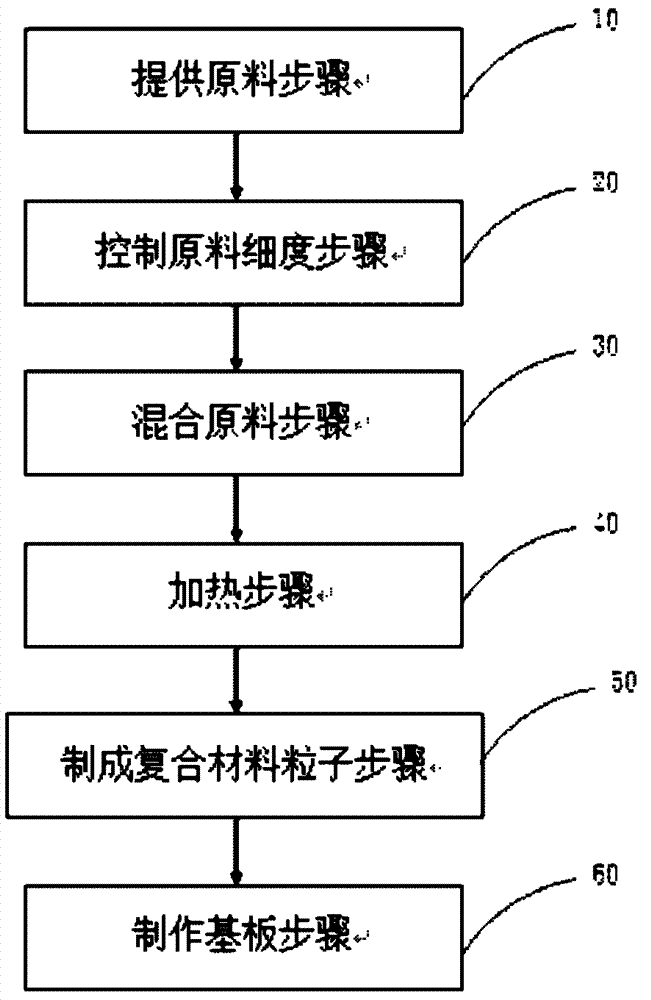

[0021] The invention provides a method for preparing a composite material substrate by mixing glass and acrylic, which comprises the following steps:

[0022] Provide raw material step 10, provide glass and acrylic;

[0023] The step 20 of controlling the fineness of raw materials includes the step of grinding glass and grinding acrylic, and making the ground glass and acrylic both nano-sized;

[0024] Mixing raw materials step 30: mixing the ground glass and acrylic, and controlling the proportion of acrylic to the total raw materials below 30%;

[0025] Heating step 40: heating the mixed raw materials to melt, and melting the mixed glass and acrylic;

[0026] Making composite material particles step 50: making the molten material into composite material particles; and

[0027] Step 60 of making the substrate: using the composite material particles to make a substrate using a molding machine, the molding machine is a plastic injection molding machine.

[0028] The above ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com