Single-crystal cast multi-wing blade

A blade and single crystal technology, applied in the field of multi-wing blades, to achieve the effects of easy production, avoiding casting difficulties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

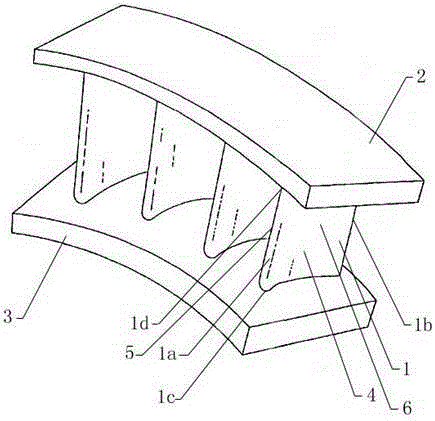

[0012] The present invention will be further described below in conjunction with the accompanying drawings: a single-crystal cast multi-wing blade, including: four blades (1), which are coupled to end wall parts (2, 3), and the blades (1) can be is a hollow single-cast single-crystal structure, can also be a solid single-cast single-crystal structure, each blade (1) has internal fluid flow channels suitable for cooling medium channels, each blade (1) has a leading edge (1a ) and the trailing edge (1b) and the outer surface (4) extending therebetween, the leading edge (1a) and the trailing edge (1b) of the blade between the first end (1c) and the opposite second end (1d) Extended, the outer surface (4) includes a convex side (5) and a concave side (6), the blade (1) is a single crystal structure, which is produced by single crystal casting technology using directionally solidified alloy composition materials, said The alloy is a second-generation directionally solidified alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com