Exposure apparatus

The technology of an exposure device and an adjustment device is applied in the field of integrated circuit equipment manufacturing, which can solve the problems of surface error and deformation of the substrate surface, and achieve the effect of realizing the adjustment of high-order wave aberration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below with reference to the drawings.

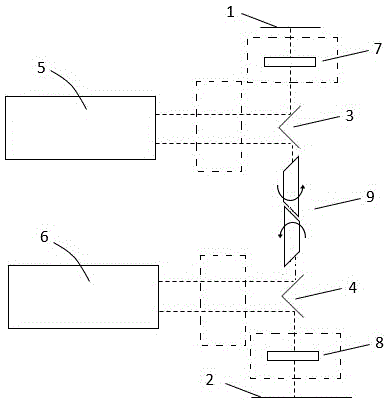

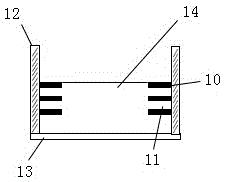

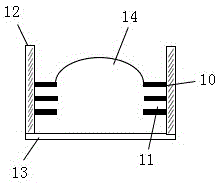

[0024] figure 1 It is a schematic diagram of the structure of the exposure device of the present invention. Such as figure 1 As shown, the exposure device sequentially includes an object plane 1, a focal plane adjustment device 7, a plane mirror group 3, a Dyson optical system 5, a prism group 9 composed of two Dove prisms, a plane mirror group 4, and a Dyson type optical system. Optical system 6, magnification adjustment device 8, image plane 2, and field diaphragm (not shown).

[0025] The dotted box shown in the figure is the possible placement position of the electroactive lens or the liquid lens, but it is not limited to the position shown in the figure. The electroactive lens or the liquid lens can also be placed in all optical paths that may adjust the image field.

[0026] The plane mirror group 3, the plane mirror group 4, the focal plane adjustment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com