A kind of porous carbon material for lithium-sulfur battery and its preparation and application

A porous carbon material and lithium-sulfur battery technology, which is applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems that cannot meet the needs of electric vehicle battery life, achieve improved sulfur fixation effects, improve overall performance, and improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

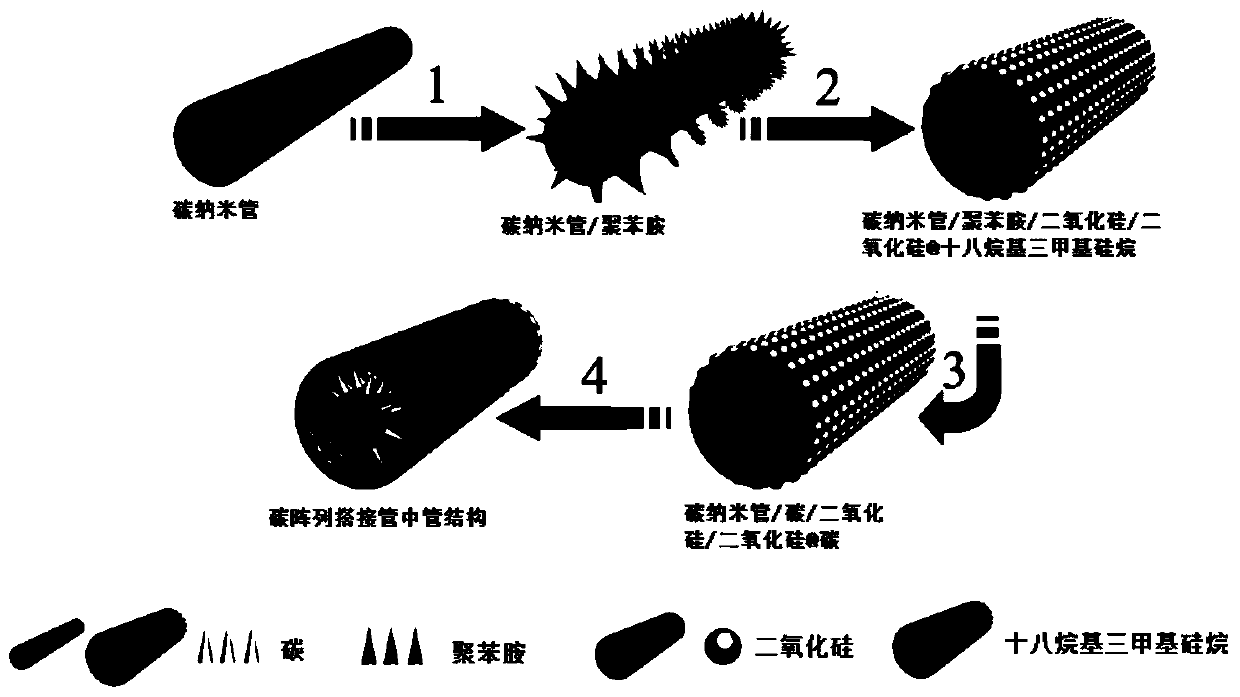

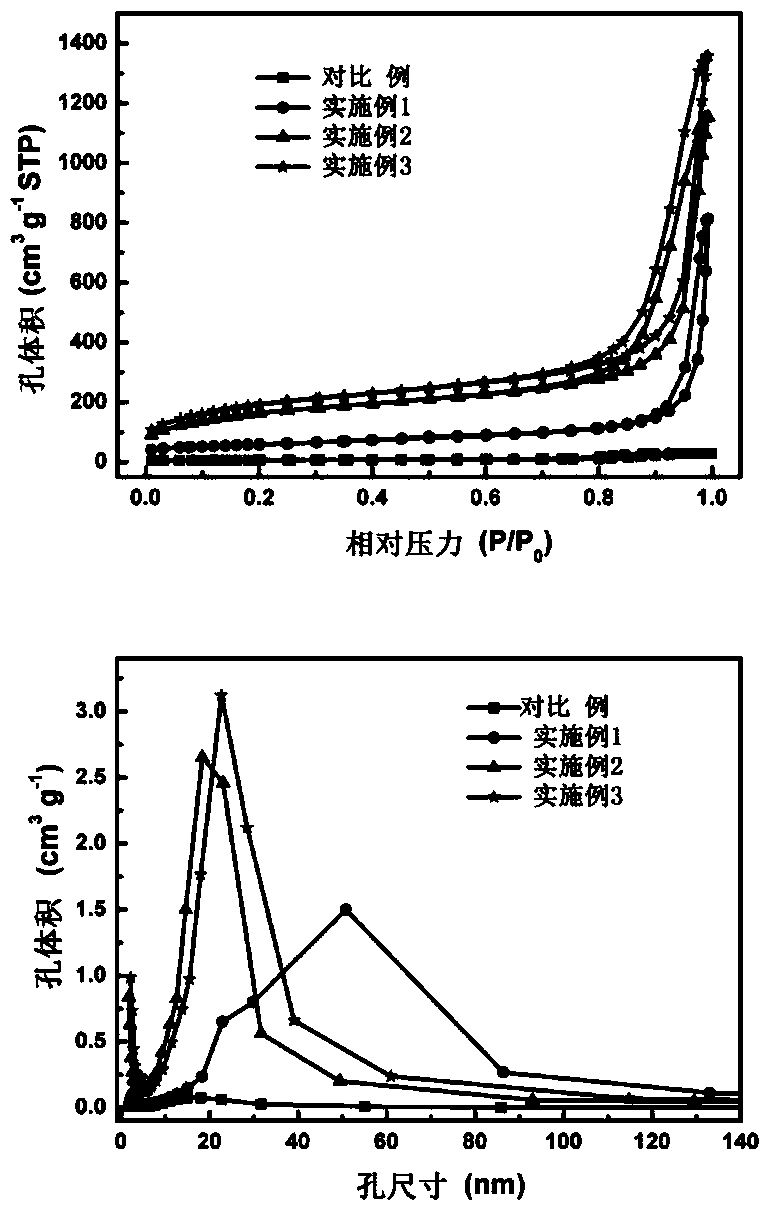

[0056] Weigh 3g of carbon nanofibers (D=100-300nm) and place them in 300mL of concentrated nitric acid, stir and reflux at 120°C for 4h, cool, and wash until neutral to obtain acidified carbon nanofibers; weigh 0.2g of acidified carbon nanofibers and add to 160mL 1M H 2 SO 4 In the solution, ultrasonic 20 ~ 60min, after fully dispersed, add 146μL aniline and 234.3mg (NH 4 ) 2 S 2 o 8 , stirred in an ice-water bath for 24 hours to obtain carbon nanofiber materials with polyaniline arrays grown on the surface; weigh 110 mg of carbon nanofiber materials with polyaniline arrays grown on the surface and place them in a mixed solution of 160 mL of ethanol and 16 mL of water, under stirring conditions , add 2mL ammonia water and 1.36mL tetraethyl orthosilicate (TEOS) solution, stir for 24h, then add 0.8mL TEOS and 0.53mL octadecyltrimethylsilane (C 18 TMS) mixed solution, stirred for 24h, suction filtered, washed, and dried to obtain carbon nanofiber materials with polyaniline a...

Embodiment 2

[0059] The carbon nanofibers in Example 1 were changed to carbon nanotubes, and other steps were the same as in Example 1.

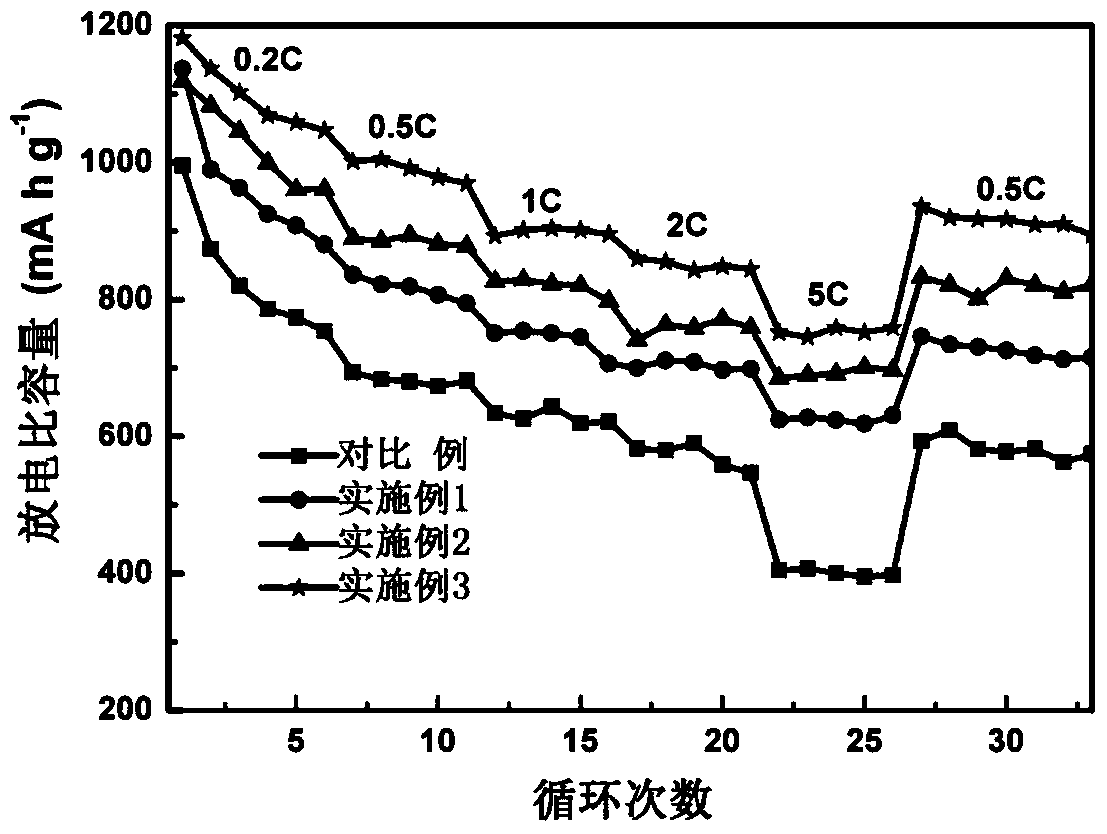

[0060] Under the discharge rate of 0.1C, the specific capacity of the first cycle discharge is 1133mA h g -1 , when the discharge rate is increased to 5C, the reversible discharge specific capacity remains 724mA h g -1 , when the discharge rate is adjusted to 0.5C, the specific capacity can be recovered to 822mA h g -1 , at 2C rate, after 100 cycles, the specific capacity is 688mA h g -1 , the capacity retention rate was 70.9%.

Embodiment 3

[0062] Weigh 3g of carbon nanotubes (D=100-300nm) and place them in 300mL of concentrated nitric acid, stir and reflux at 120°C for 4h, cool, and wash until neutral to obtain acidified carbon nanotubes; weigh 0.2g of acidified carbon nanotubes and add them to 160mL 1M H 2 SO 4 In the solution, ultrasonic 20 ~ 60min, after fully dispersed, add 146μL aniline and 234.3mg (NH 4 ) 2 S 2 o 8 , stirred in an ice-water bath for 24 hours to obtain carbon nanotubes with polyaniline arrays grown on the surface; weigh 300 mg of carbon nanotubes with polyaniline arrays grown on the surface and place them in 300 mL deionized water for ultrasonication for 1 hour, add 100 mg Tris, and then add 180 mg Dopamine, stirred for 24h, then added 200mg of sucrose, stirred for 24h. In an ultrasonically mixed solution,

[0063] Under the discharge rate of 0.1C, the specific capacity of the first cycle discharge is 1181mA h g -1 , at a discharge rate of 0.1C, the specific capacity of the first cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com