Device and method for testing bond performance between reinforced bar and concrete under repeated load

A bonding performance and test device technology, which is applied in the direction of measuring device, testing material strength by applying repetitive force/pulsation force, and analyzing materials, can solve the problems of cumbersome loading operation process, increase test error, test error, etc., and achieve It is convenient for loading and unloading and test operation, improves the efficiency of disassembly and assembly, and improves the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

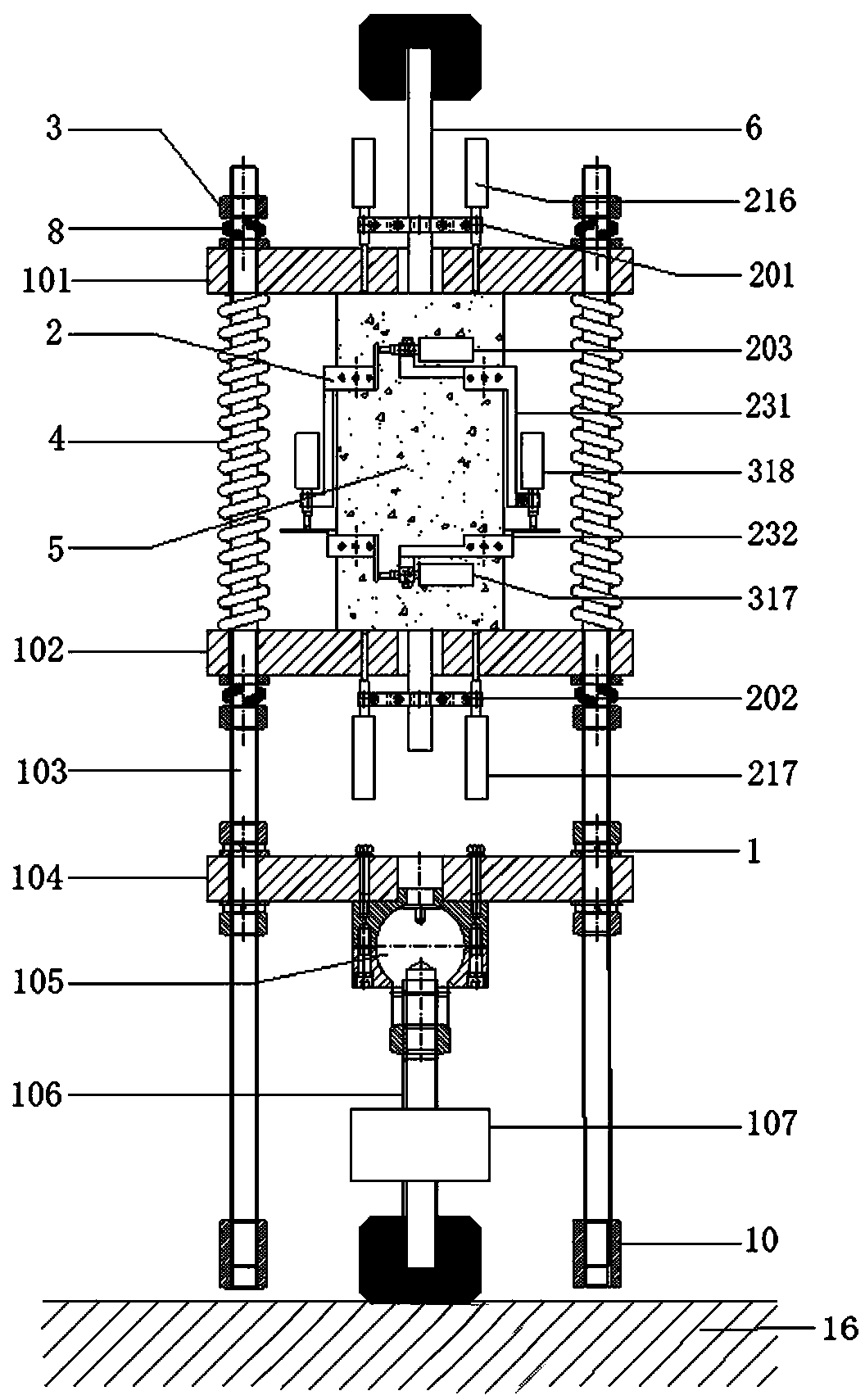

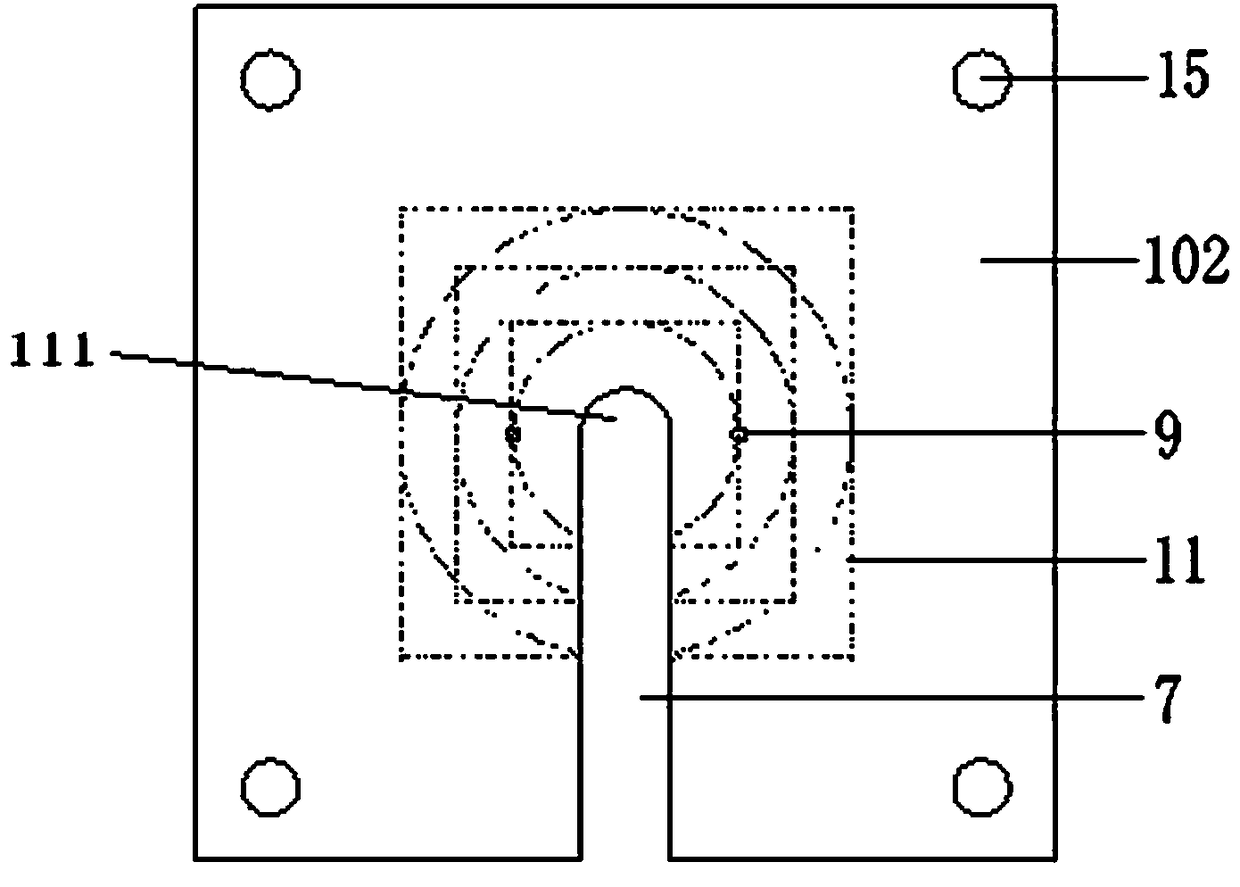

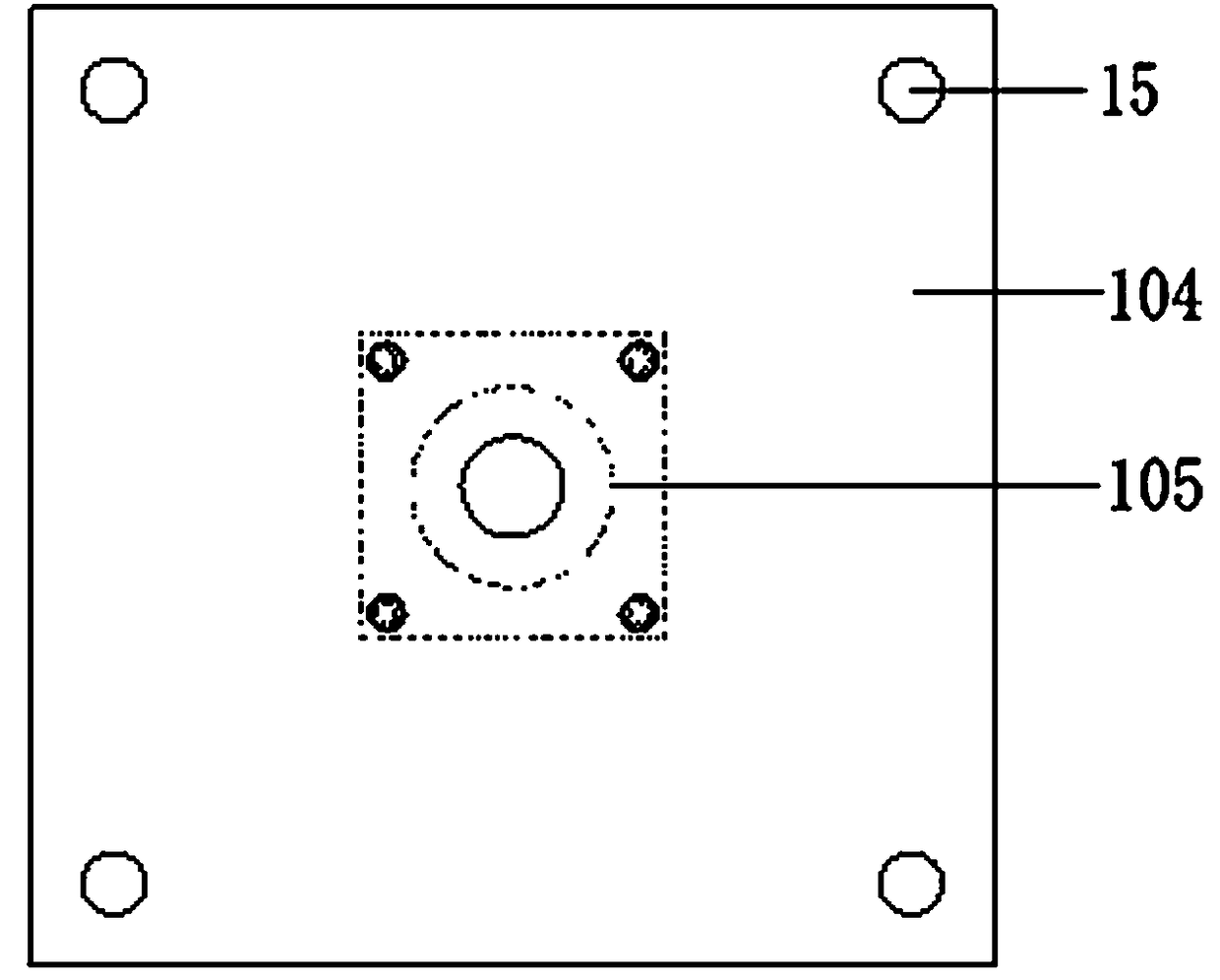

[0045] The device for testing the bonding performance of reinforcement and concrete under repeated loads of the present invention includes a loading frame 1 and a strain sensor mechanism 2; the loading frame 1 includes an upper loading plate 101, a lower loading plate 102, a screw rod 103, and a force transmission plate 104 , a ball hinge assembly 105 and a connecting rod 106, the four corners of the upper loading plate 101, the lower loading plate 102 and the force transmission plate 104 are provided with screw holes 15, and the screw holes 103 pass through the screw holes 15 and pass through the screw holes respectively. The fastening nut 3 arranged on the rod 103 is connected to form an integral loading frame, and the screw rod 103 between the upper loading plate 101 and the lower loading plate 102 is equipped with a spring 4 to support the upper loading plate 101. The center of the upper and lower loading plates 101, 102 is provided with a reinforcement through hole 111 for...

Embodiment 2

[0063] The same as Embodiment 1 will not be repeated, the difference is: the screw rod 103 between the upper loading plate 101 and the lower loading plate 102 is sleeved with supporting nuts 12 to support the upper loading plate 101, so A spring washer 8 is arranged on the screw rod 103 between the support nut 12 and the upper loading plate 101 .

Embodiment 3

[0065] The same as Embodiment 1 will not be repeated, the difference is: the center of the upper and lower loading plates 101, 102 is provided with a rib through hole 111 for the passage of the ribs, and the upper loading plate 101 and the lower loading plate 102 No test piece mounting groove 7 is provided on the edge of the plate from the center to one side. When installing the test piece base 5 , the upper loading plate 101 needs to be disassembled from the screw rod 103 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com