Shoe pad

A technology of insole and support layer, applied in the field of insole, can solve the problems of lack of insole comfort, insole flexibility, poor durability, etc., and achieve the effect of improving comfort, good elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

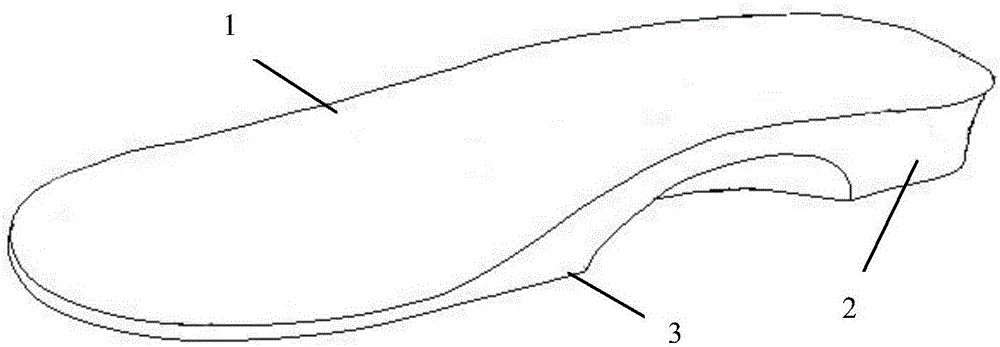

[0030] Such as figure 1 As shown, the insole of the present invention includes a surface layer 1, a support layer 2 and a bottom layer 3. The support layer 2 can be integrally formed by 3D printing, or can be manufactured by other technologies. The surface layer 1 is located on the upper surface of the support layer 2 and is in direct contact with the sole of the foot. The surface layer 1 can be directly manufactured with the support layer 2 by 3D printing to form an integrated structure, or rubber, leather, EVA and other materials can be used to attach to the surface of the support layer. The bottom surface layer 3 is located on the bottom surface of the support layer 2 and is in contact with the sole. The bottom surface layer 3 can be directly manufactured with the support layer 2 by 3D printing to form an integrated structure. It can also be attached to the support layer by using materials such as rubber, leather, and EVA. bottom surface.

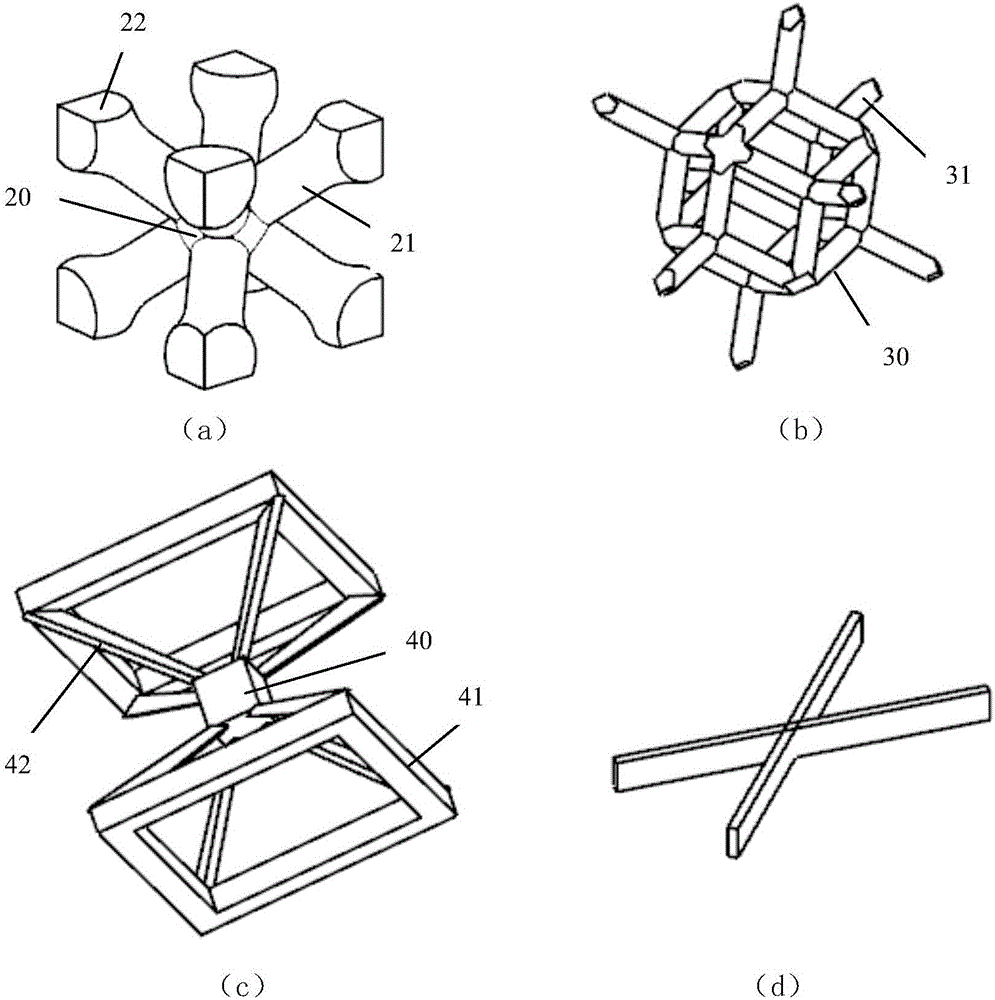

[0031] The support layer is wov...

Embodiment 2

[0035] The principle and structure of this embodiment are basically the same as that of Embodiment 1, except that different filling units are used to weave at different positions on the longitudinal section and / or cross section of the support layer, so as to realize different elasticity of different parts of the insole and improve wearing comfort. comfort.

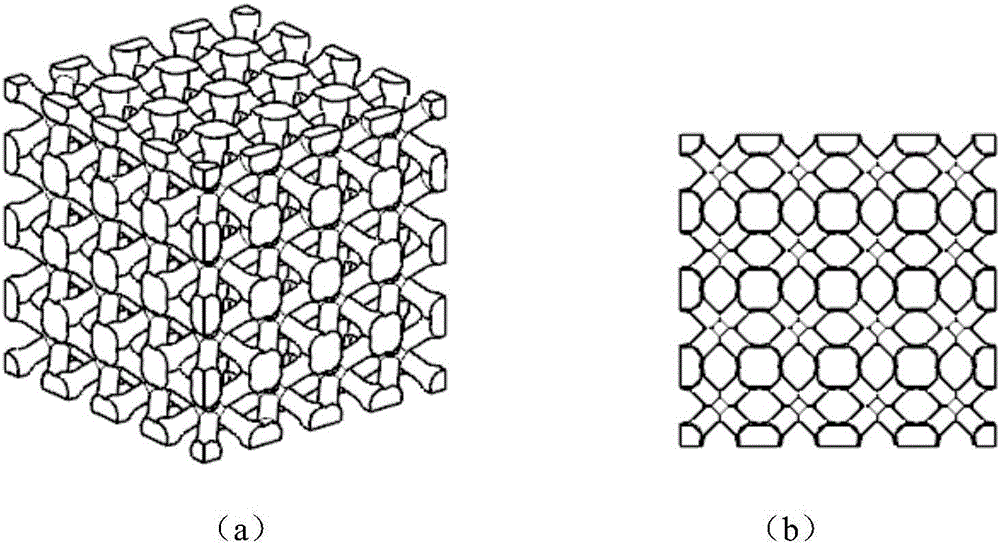

[0036] A variety of structures of filling units are woven to form a support layer, such as Figure 8 , 9 and 10. Figure 8 The shown insole support layer, its sole position 83, heel position 80, foot arch position 82 and other positions 81 of the foot are woven by using different filling units respectively, as Figure 9 shown. In addition to the different structures of the filling units, the weaving density can also be different, such as Figure 10 As shown, the weaving density of the support layer part near the sole is smaller than that of the support layer part near the sole. exist Figure 10 In the filling structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com