Boxing sandbag with improved structure

A boxing and sandbag technology, applied in the field of fitness equipment, can solve the problems of high manufacturing cost, cumbersome installation, and high transportation cost, and achieve the effects of improving safety in use, saving transportation costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

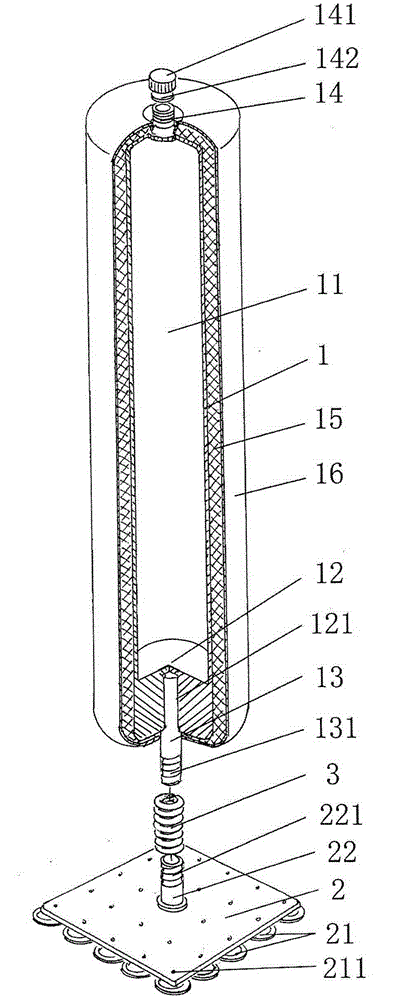

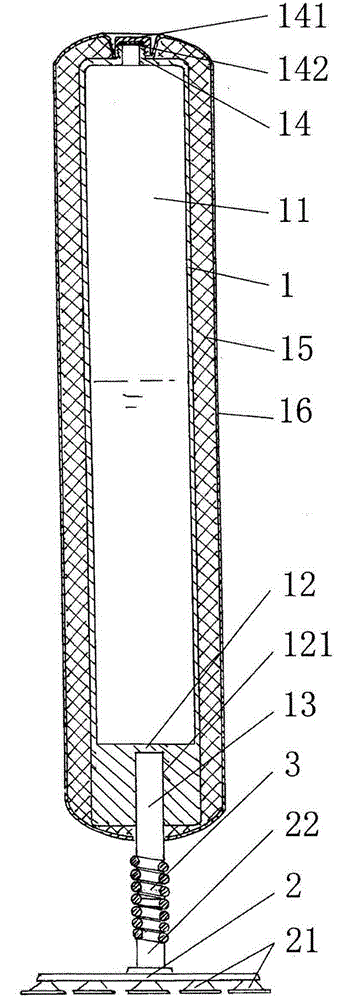

[0021] see figure 1 , figure 2 , the present invention relates to a boxing sandbag with improved structure, comprising a cylinder 1, a base 2 and a spring 3, the cylinder 1 is connected to the base 2 through the spring 3, and the characteristics are: the cylinder 1 There is a medium cavity 11 inside, and an upper column fixing seat 12 is formed at the bottom of the column cylinder 1 in the height direction. An upper column insertion cavity 121 is opened at the center of the upper column fixing seat 12. The opening of the upper column insertion cavity 121 faces Next, one end of an upper column 13 is embedded in the upper column insertion cavity 121, and the other end of the upper column 13 extends downward and protrudes from the lower bottom surface of the column tube 1, and at the same time forms a There is an upper spiral groove 131, and a medium inlet and outlet 14 protrudes from the center of the top of the cylinder 1 in the height direction. The medium inlet and outlet 1...

Embodiment 2

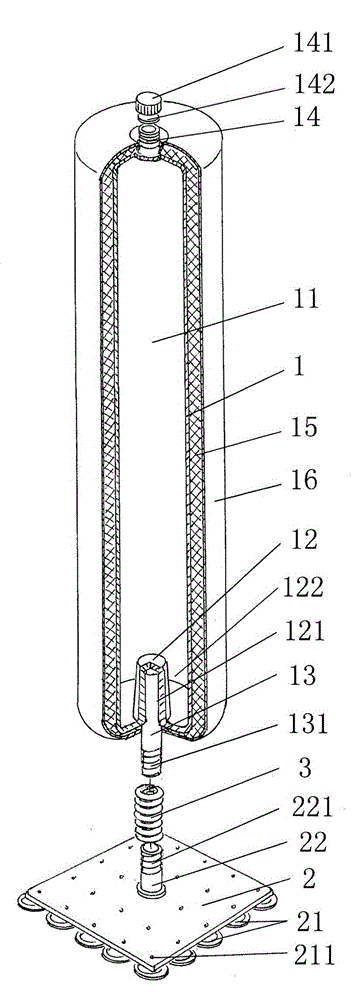

[0027] see figure 1 , figure 2 and combine image 3 , the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that: the bottom of the cylinder 1 in the height direction is recessed into the medium chamber 11 with an upper column fixing seat 12, and the center of the upper column fixing seat 12 is There is an upper column insertion cavity 121, and there is a certain space between the upper column fixing seat 12 and the wall of the column tube 1 and forms a circle of medium relief groove 122, which communicates with the medium chamber 11, so that The medium relief groove 122 reduces the production cost of the column 1 and further reduces the weight of the column 1, which is more conducive to reducing the transportation cost.

Embodiment 3

[0029] see figure 1 , figure 2 and combine Figure 4 The structure of the third embodiment is basically the same as that of the first embodiment, except that the lower end of the lower column 22 is fixedly connected with the connection plate 23, and the connection plate 23 is installed on the connection seat 24 through the connection plate fixing screw 231, And this connection base 24 is fixed on the pile base 25 by the connection base fixing screw 241 again, and described pile base 25 is comparatively heavy and difficult to overturn, has good grip performance, has improved the stability of boxing sandbag.

[0030] see figure 1 , figure 2 , image 3 and combine Figure 4 , describe the use method of the present invention: when in the transportation state, there is no medium in the medium chamber 11, the weight of the sandbag is reduced to the minimum, which can effectively reduce the transportation cost; and when it is put into use, the column cylinder 1, Base 2 and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com