Powder catalyst dipping method

A catalyst and powder technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as poor impregnation effect and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

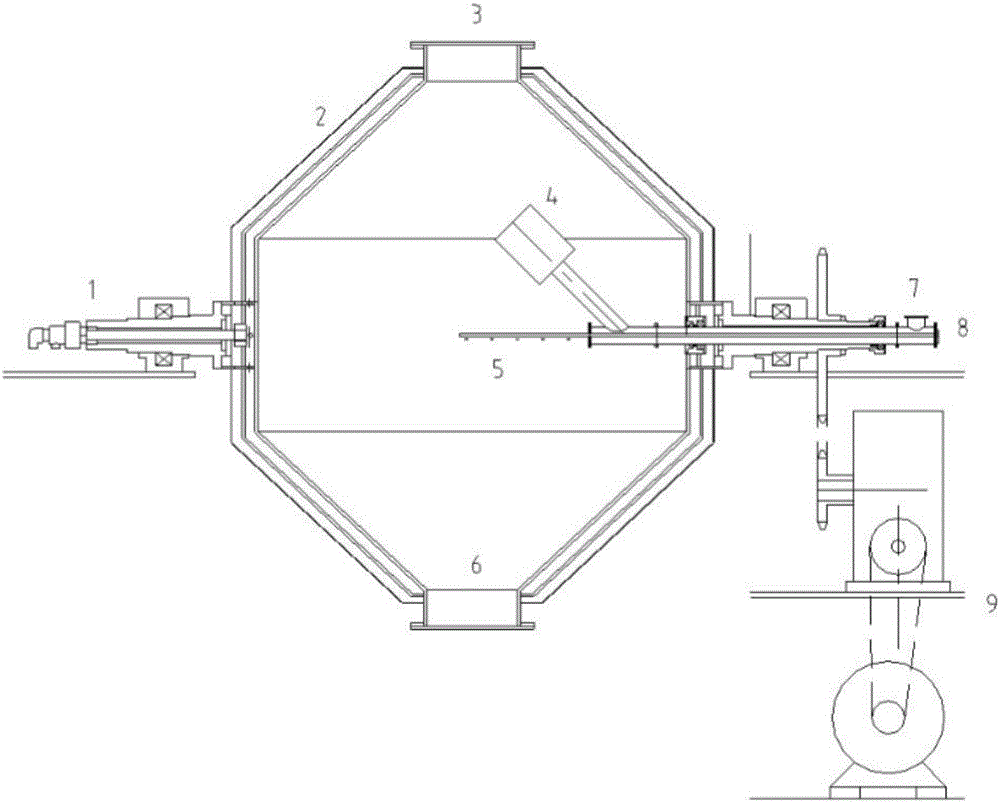

Image

Examples

Embodiment 1

[0017] The invention is applied to the impregnation preparation process of a coal chemical (methanol to aromatics) catalyst. The catalyst has an average particle size of 80 μm and a bulk density of 0.8 g / cm 3 . The impregnation body equipment is connected to the weighing system through the quick-connect flange, and after 400kg of catalyst carrier is put in, the flange is disconnected and the feed inlet is closed; steam is introduced to heat the container, and the temperature is controlled at 60°C; through the impregnation liquid pipe Add 410kg of measured impregnating solution, and the equipment starts to turn over for 20 minutes, shake for 30 minutes, and shake for 10 minutes according to the program requirements; after the impregnation is completed, age for 2 hours; after aging and reduction, turn on the vacuum system for vacuum drying, and set the temperature at 60°C , when turning over and drying, the equipment performs three cycles of movement for a total of 60 minutes ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com