Side-fixed wheel guard flanging die

A flanging mold and wheel cover technology, which is applied to wheels, forming tools, manufacturing tools, etc., can solve problems such as low production efficiency, poor product quality, and difficult mold debugging and maintenance, and achieve simple operation, simple structure, and stable state Effect

Inactive Publication Date: 2017-04-05

宋琳

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problems of difficulty in mold debugging and maintenance, low production efficiency and poor product quality, the invention provides a laterally fixed wheel cover flanging mold

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

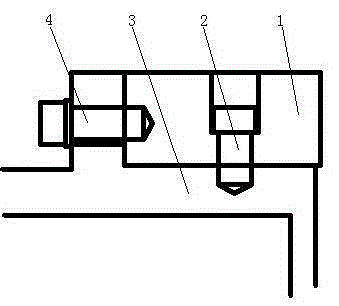

[0009] As shown in the figure, a transverse screw 4 is added between the side of the insert 1 and the mold base 3 . When assembling, install the insert 1 on the mold base 3 with the vertical screw 2 first, and then fix the insert 1 through the mold base 3 with the transverse screw 4 on the side. During mold maintenance, it is easy to adjust the mold flanging clearance by adjusting the length of the side transverse screw 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A side-fixed wheel guard flanging die comprises a die seat and an insert. The side-fixed wheel guard flanging die is characterized in that a transverse screw is additionally arranged between the side face of the insert and the die seat. The side-fixed wheel guard flanging die overcomes the defects that a die is difficult to debug and repair, low in production efficiency and poor in product quality and is widely suitable for being used for assembly of automotive wheel guard flanging dies.

Description

technical field [0001] The invention relates to the field of automobile moulds, in particular to a side-fixed mould, which is used for wheel cover flanging. Background technique [0002] At present, for the flanging molds of products such as automobile wheel covers, the front vertical positioning pins are usually used to fix the positioning when designing and manufacturing the molds. It is difficult to adjust the clearance of the mold flanging, which makes it difficult to debug and maintain the mold, and affects the production efficiency and product quality. Contents of the invention [0003] In order to solve the problems of difficulty in mold debugging and maintenance, low production efficiency and poor product quality, the invention provides a laterally fixed wheel cover flanging mold. [0004] The technical solution of the present invention is a side-fixed wheel cover flanging mold, including a mold base and an insert, and the special feature is that a transverse scre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21D37/10B21D53/32

Inventor 宋琳

Owner 宋琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com