Device for rotary cutting of blocky dry ice

A rotary cutting device and dry ice technology, which is applied in metal processing and other directions, can solve the problems of unable to carry out regular rotary cutting, pollute dry ice, and difficult to maintain the shape, etc., and achieve the effect of simple and controllable path, uniform transportation, and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

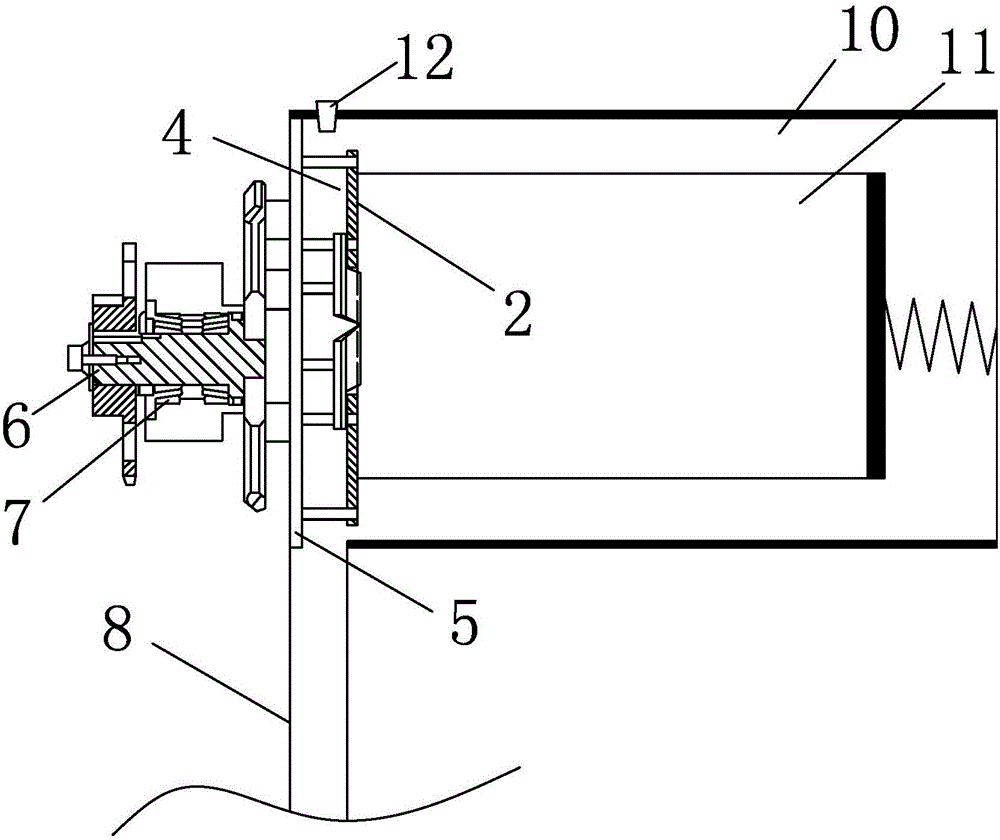

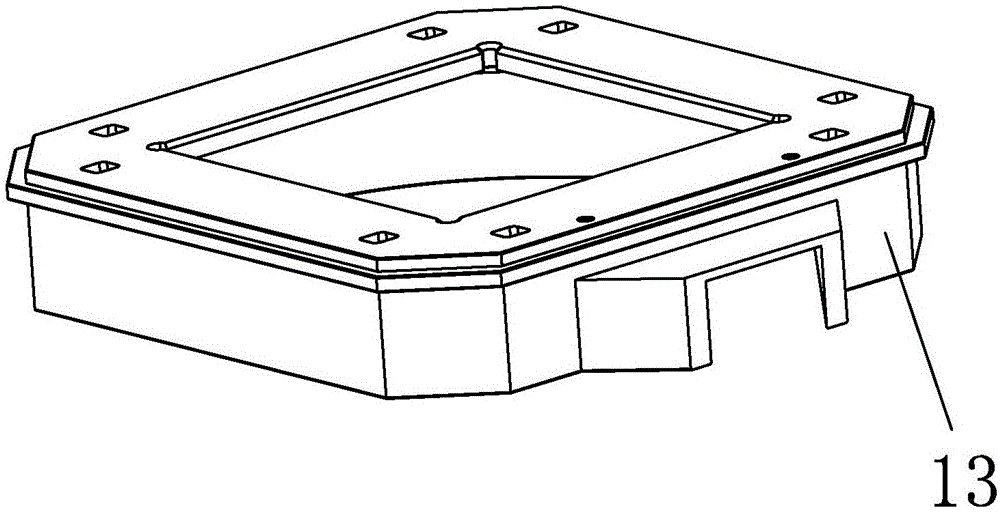

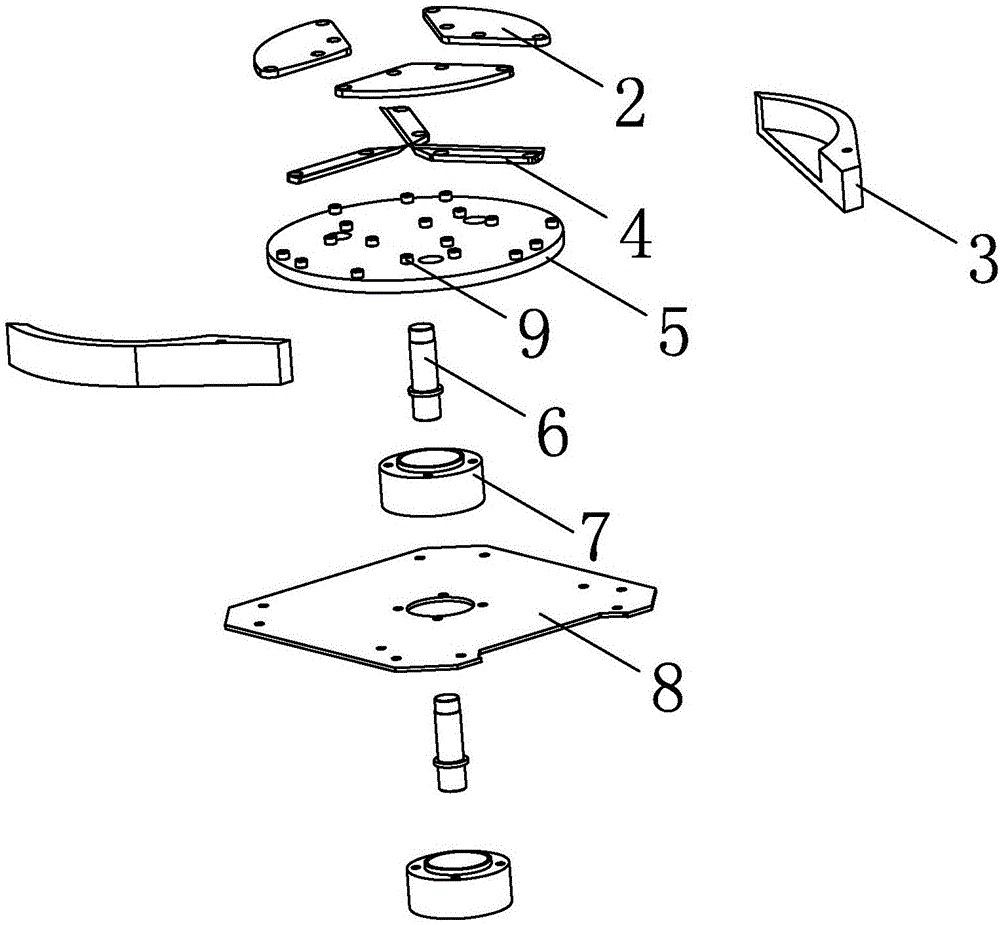

[0019] like figure 1 As shown, the block dry ice rotary cutting device of the present embodiment includes: a container (10), used to place dry ice (11), the first side of the container is provided with a pressing device (12), which pushes the dry ice to the second side, the second side is provided with a rotary cutting plate as a rotary cutting side plate, which is a side plate of the container, and the side plate includes a rotatable rotary cutting plate (5), such as figure 2 , image 3 As shown, it is generally circular, and it is fixed with a blade (4), a support plate (2), the blade (4) and the support plate (2) are generally on the same plane, and the sharp end of the blade (4) protrudes outward. Support plate (2), can stretch out 0.5-2 millimeter, or carry out proper adjustment according to the loose degree of dry ice. Between the rotary cutting board (2) and the blade (4) and the supporting board (3), there is a retaining column (9), whose function is to leave a cer...

Embodiment 2

[0020] Embodiment 2: as Figure 4 , 5 , shown in 6, it is different from embodiment 1 in that the support plate is canceled, and the blade is changed to a scraper, and the scraper is as Figure 7 As shown, it includes a plane (2.1), an opening (2.2), and a blade (2.3), the scraper (2) is fixed on the rotary cutting board (5), and there is a post between the scraper (2) and the rotary cutting board ( 9), the scraper rotates with the rotary cutting plate (5), and the blade (2.3) protrudes out of the plane (2.1), and the dry ice is rotary-cut and dropped from the opening (2.2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com