High-precision heating furnace steel drawing positioning control method

A positioning control and heating furnace technology, which is applied in heat treatment process control, heat treatment furnaces, furnaces, etc., can solve the problems of excessively long advance of the steel pumping machine, unstable slab support, and steel jamming of the slab, so as to reduce positioning deviation , reduce the frequency of steel jamming, and improve the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

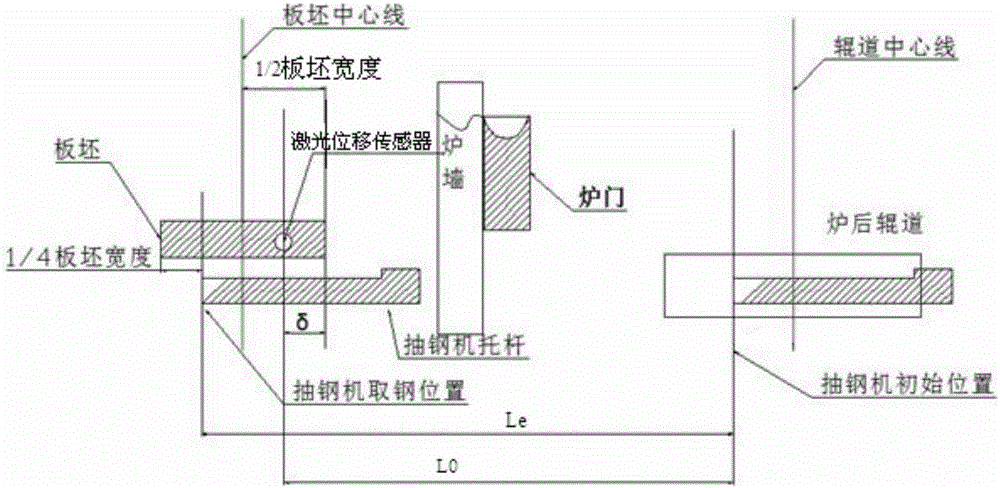

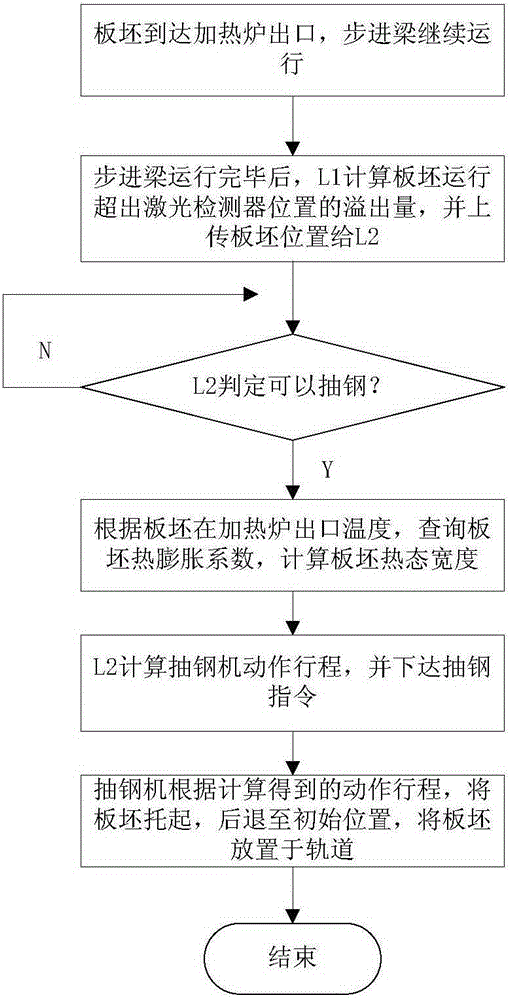

[0039] Such as figure 2 As shown, the specific control process of the present application is as follows:

[0040] Step 1. The laser displacement sensor at the discharge end of the heating furnace sends laser pulses in real time to detect the position of the slab. When the walking beam sends the slab to the exit of the heating furnace, the laser displacement sensor at the discharge end of the heating furnace detects the slab and heats it. The laser displacement sensor at the discharge end of the furnace is switched on, and the walking beam continues to walk in order to complete the running stepping cycle. At the same time, the first-level computer L1 reads the data measured by the laser displacement sensor at this time.

[0041] Step 2: After the walking beam runs, the first-level computer L1 reads the data measured by the laser displacement sensor again, calculates the overflow amount of the slab running beyond the position of the laser displacement sensor, and uploads the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com