Underwater garbage dredger with anti-wrap scraper

An anti-winding scraper and anti-winding technology, which is applied to special-purpose ships, warships, earth movers/shovels, etc., can solve the problems of high dredging quality, soft garbage entanglement, and damage to the cutter head, etc. The effect of high silt quality, reduced dredging cost, and improved dredging work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

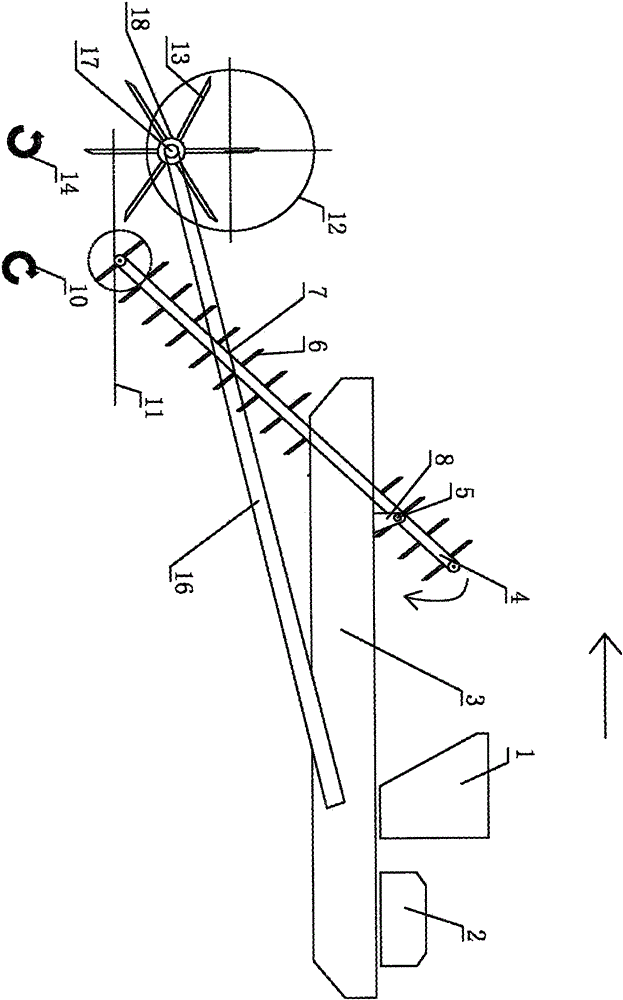

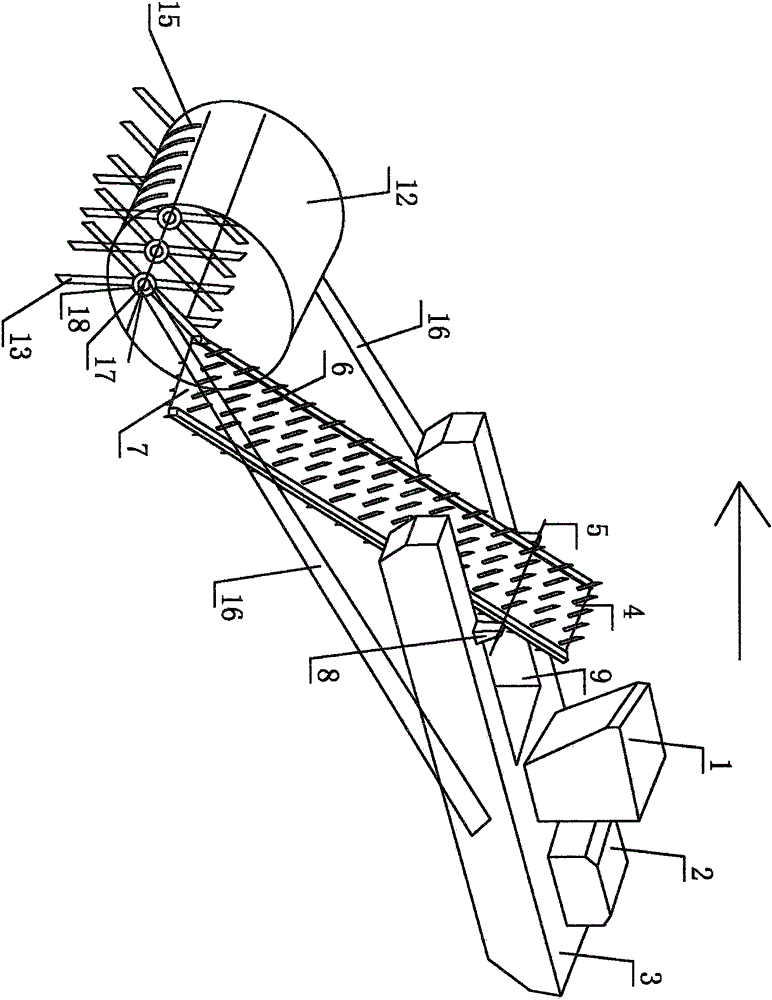

[0012] Such as figure 1 , figure 2 As shown, the present invention is an underwater garbage dredging ship with an anti-winding scraper, including an operating room 1, a power unit 2, a hull 3, a mud storage tank 9, a front cleaning device 4 with a knife-tooth conveyor belt, and a bracket 8. The anti-winding scraper 12 is characterized in that: the operating room 1 and the power unit 2 are arranged at the rear of the hull 3, the mud storage tank 9 is arranged in the middle of the hull 3, and the front cleaning device 4 is equipped with a knife-toothed conveyor belt. , the bracket 8 is arranged on the front part of the hull 3, the lower end of the bracket 8 is fixedly connected with the hull 3, the upper end of the bracket 8 is connected with the pre-type cleaning device 4 with the toothed conveyor belt through the bracket shaft 5, and the front-type conveyor belt with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com