Continuous variable valve lift system control method and system and vehicle

A valve lift and control method technology, applied in engine control, output power, machine/engine, etc., can solve problems such as affecting valve lift, single lift mode, and valve lift consistency, and achieve consistency. , to avoid the effect of machining tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

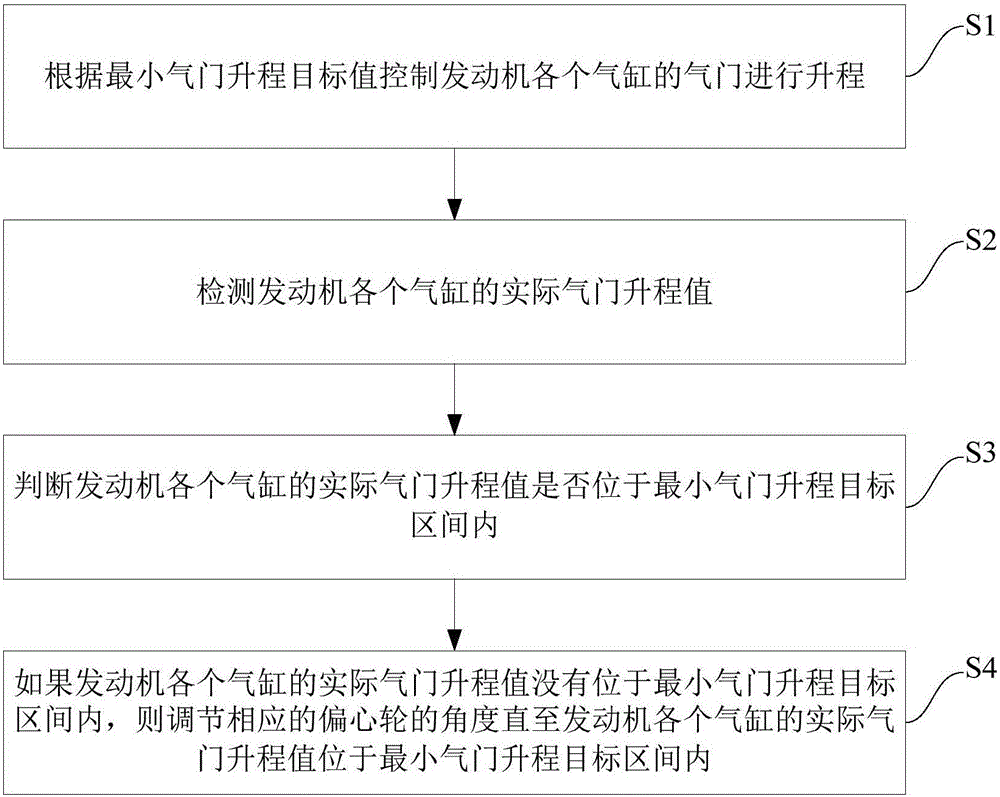

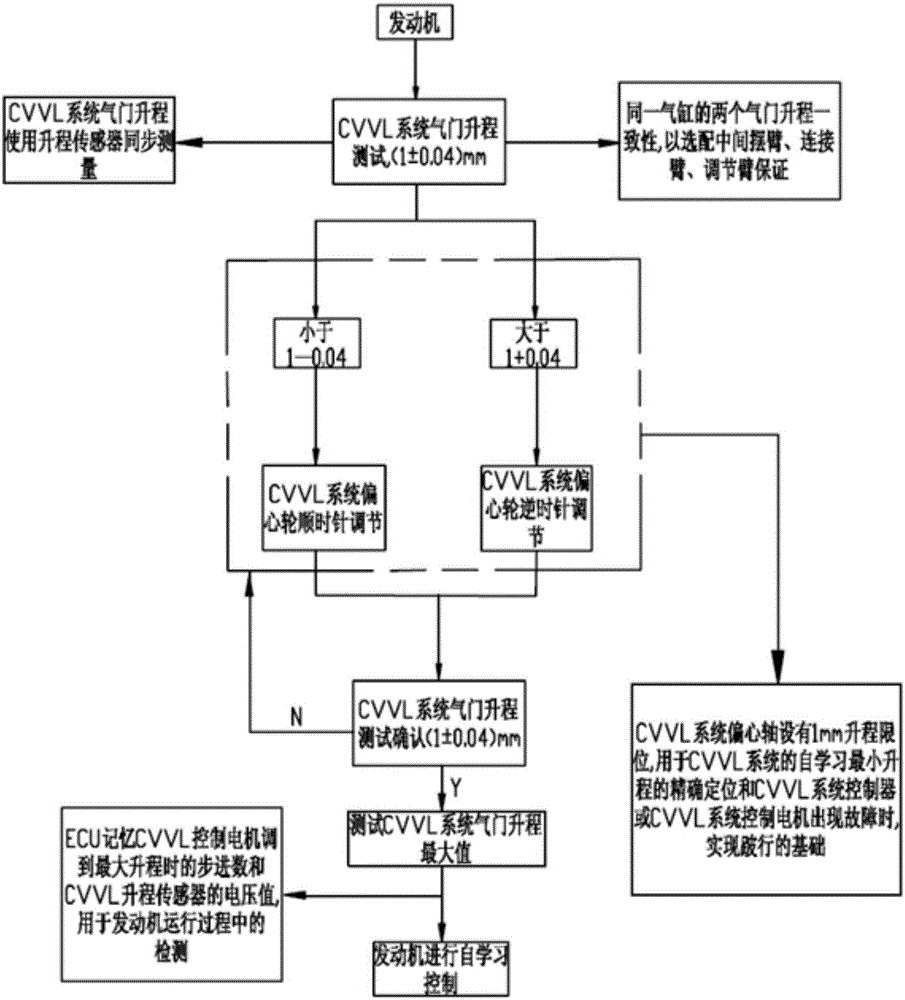

[0035] figure 1 It is an overall flow chart of the control method of the continuously variable valve lift system according to an embodiment of the present invention. figure 2 It is a detailed flowchart of a control method of a continuously variable valve lift system according to an embodiment of the present invention.

[0036] Such as figure 1 shown, combined with figure 2 , a control method for a continuously variable valve lift system according to an embodiment of the present invention, comprising the following steps:

[0037] S1: Control the lift of the valves of each cylinder of the engine according to the minimum valve lift target value.

[0038]S2: Detect the actual valve li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com