Industrial rubber drying device

A drying device and rubber technology, applied in the direction of heating devices, drying, dryers, etc., can solve the problems of unreasonable structural design of drying equipment, achieve good drying effect, reasonable structural design, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

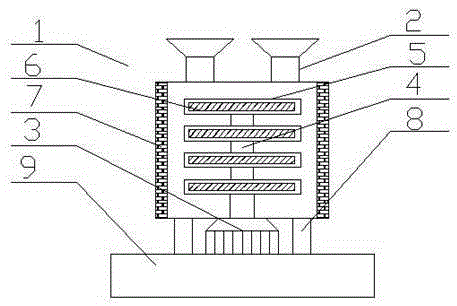

[0010] Such as figure 1 As shown, an industrial rubber drying device includes a body 1, the body 1 includes a feed port 2, a frequency conversion motor 3 and a pallet 5, and a plurality of feed ports 2 are arranged above the body 1; the body 1 is provided with a base 9; between the base 9 and the body 1 is provided with a frequency conversion motor 3; the output part of the frequency conversion motor 3 is connected to a connector 4; and the surface of the connector 4 is provided with a plurality of supporting plates 5 ; The inner wall of the body 1 is provided with a layer of heating layer 7 .

[0011] The electric heating tube 6 provided inside the supporting plate 5 can fully heat the material, effectively remove the moisture contained in the material, and improve the working efficiency.

[0012] The above are the embodiments of the present invention, so all equivalent changes or modifications made according to the structure, features and principles described in the scope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com