Cutting guide plate top mechanism

A positioning plate and cross-shaped technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unstable positioning and low production efficiency, and achieve the effect of convenient operation, simple structure and stable positioning state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

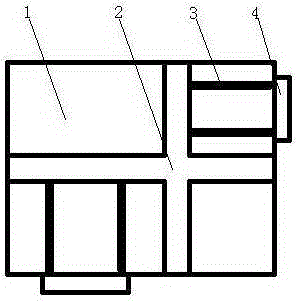

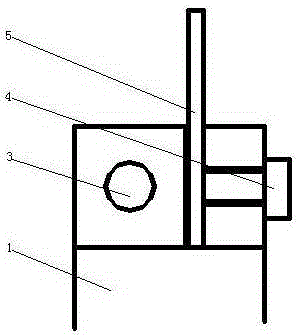

[0010] As shown in the figure, there is a cross-shaped notch 2 on the top of the positioning plate 1 where the positioning position is required, and threaded holes 3 are added in the front, rear, left and right directions.

[0011] During work, if it is necessary to increase the auxiliary pattern plate 5 in the front and rear directions, the auxiliary pattern plate 5 is put into the horizontal notch 2 and fixed with screws 4; Put it into the longitudinal notch 2 and fix it with screw 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com