Warm-hot forming method of seamless tunnel pipe with large radius-thickness ratio

A large diameter-to-thickness ratio, warm forming technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that the diameter-to-thickness ratio cannot be directly formed, the diameter ratio is limited, and the tunnel tube is too large to achieve shortening The production cycle and tooling are simple and easy, and the effect of eliminating longitudinal welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A method for thermoforming a seamless tunnel pipe with a large diameter-to-thickness ratio, comprising the following steps:

[0034] S1: Select the original pipe material, conduct mechanical performance test, wall thickness inspection, and meet the national standard of the corresponding material, intercept a part of the seamless pipe blank 1 from the selected original pipe material, clean it, and remove surface oil and impurities;

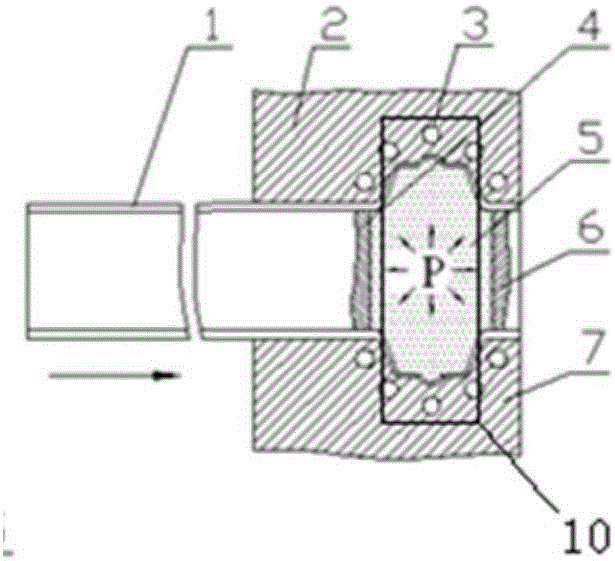

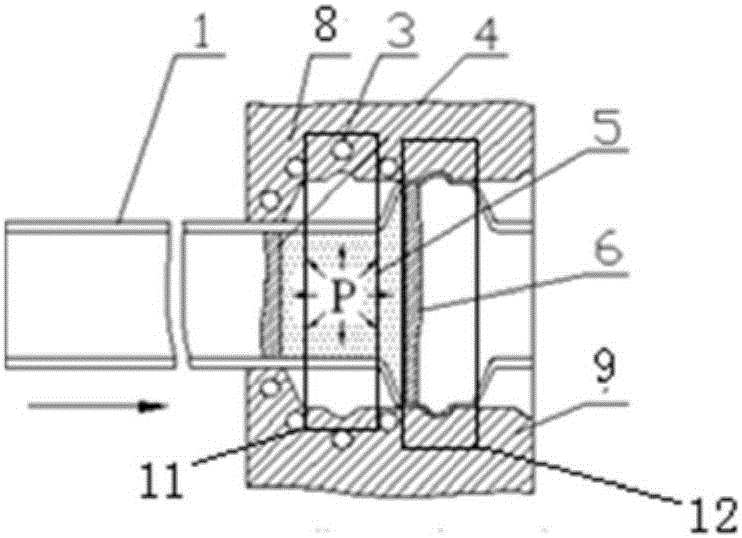

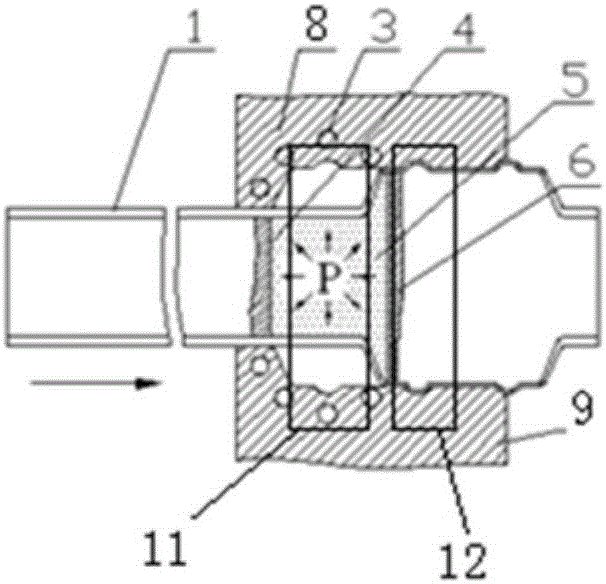

[0035] S2: heating the upper mold half A2 and the lower mold half A7 through the heating coil 3, and the upper mold half A2 and the lower mold half A7 can form a cavity A10;

[0036] S3: The first corrugation of the tube blank 1 is formed; open the upper half mold A2 and the lower half mold A7, place the tube blank 1, close the upper half mold A2, the lower half mold A7, place the left head 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com